Vesta Spiral Freezer

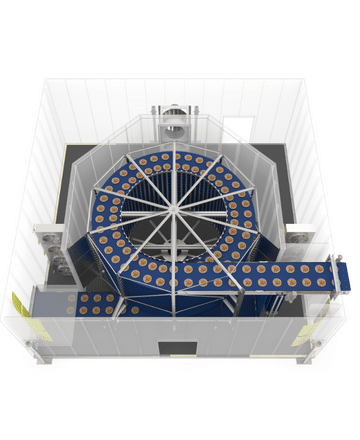

The Spiral Freezer by AMF Vesta achieves the perfect freezing conditions with exceptional continuous air displacement, creating a cold, smooth, and uniform flow of air around each product.

Key benefits

- Automatic defrost sequence — initiated one section at a time — allows for continuous operation.

- Blast Freezing System provides quick and even product freezing.

- Plastic modular belting mitigates potential jams or downstream process complications.

- Low-friction rails for belting minimize energy consumption.

- Optional internal drum access platform eases maintenance and sanitation.

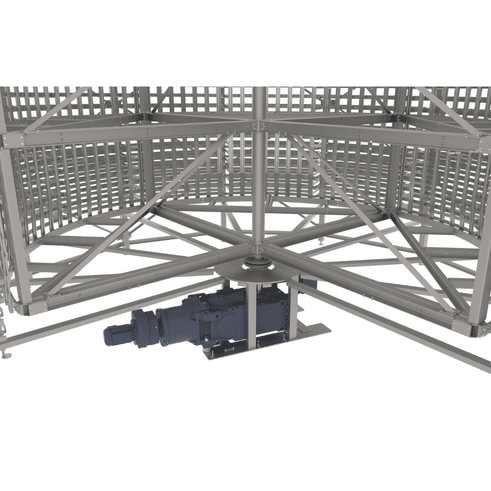

- Monopiece cage bar design offers efficient installation and improved access for cleaning and maintenance.

Product Applications

The Vesta Spiral Freezer is suitable for freezing a wide variety of baked products, including:

- Pizza

- Pastries

- English Muffins

- Croissants

- Pies

- Soft Bread, Buns, & Rolls

- Artisan Bread & Rolls

- and more!

Improved Air Movement & Automatic Defrost Sequence

Vesta Spiral Freezer Defrost Loop

The AMF Vesta Spiral Freezer defrost cycle helps prevent ice from building up and completely shutting down operations. Customized to meet your production needs, the automatic and distinct defrost cycle initiates heating elements one section at a time for optimal energy efficiency. Remaining operating coils guarantee an equal freezing flow to preserve products’ freezing quality, mitigate heat gain, and minimize temperature fluctuations. Melted frost is collected by related heated catch pan and drained outside the enclosure.

What’s New at AMF Vesta

Article

Article

Article

Access the Vesta Spiral Freezer Brochure

Request More Information About the Vesta Spiral Freezer

At AMF Vesta, we’re committed to supporting bakeries around the world with the highest quality equipment to optimize operations, improve product quality, and grow your bakery. Fill out this form to connect with a thermal services specialist.

Local Support,

Globally

At AMF, the proof of our success is when our customers rise to the top. AMF is the only complete baking solutions provider with locations worldwide. We help bakeries minimize their risks and stay online with local service and support around the globe.