AMF Den Boer Multibake D

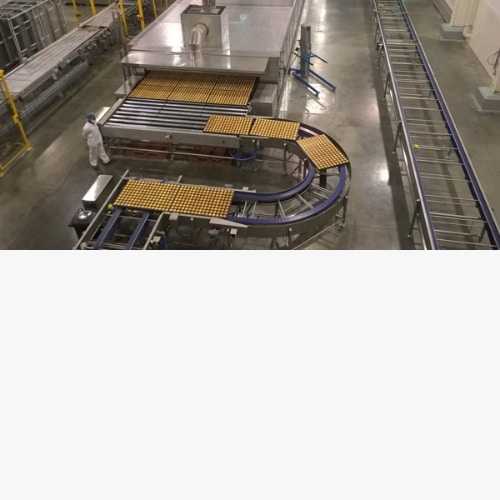

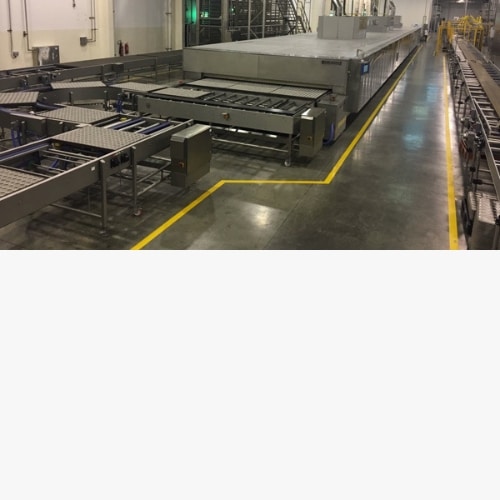

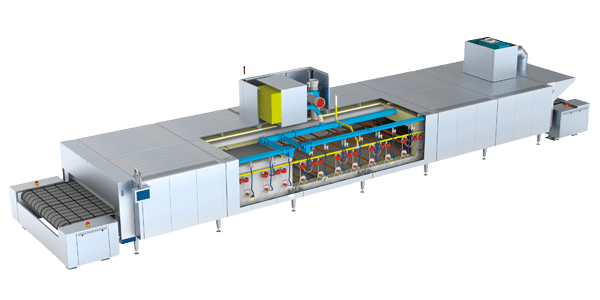

The Multibake® D Tunnel Oven by AMF Den Boer is a direct-fired oven for industrial bakeries. The required heat is created directly in the baking tunnel by means of modulating multi-ribbon gas burners. There are four burners in each standard module: two burners directly above and two burners beneath the products to be baked. The modular construction of the baking tunnel guarantees an even heat transfer to the product.

Key benefits

- Dependable, adjustable heat transfer from top and bottom.

- Optional moisture monitoring and steam injection.

- Automatic gap detection.

- Optional convection unit provides air movement between the burners.

- Diffusor pipes surrounding the top burners provides a gentle bake by the tubes’ radiation.

- Heat transfer from the combustion gases of the burners to the product is direct without any transfer losses.

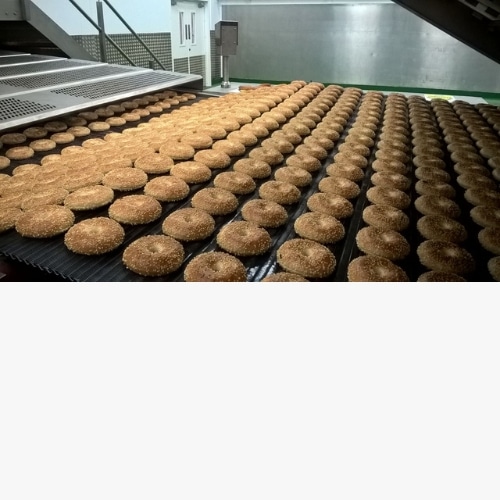

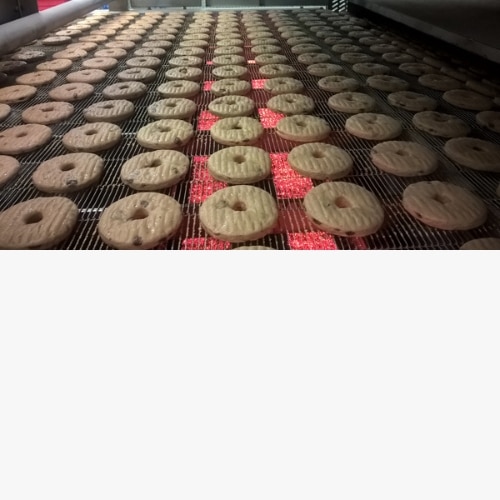

Product Applications

Achieve the Desired Baking Curve

PRECISE TEMPERATURE CONTROL

The temperature is measured via PT-100 sensors fitted in the baking tunnel in each zone above and below the product. The measured values for each zone can be read on the central control panel (touch panel).

The burners are controlled via a processor system, making it possible to control the top and bottom temperature in each zone. If the set temperature deviates from the measured temperature, the modulating burners are subsequently adjusted by means of P.I.D. temperature regulators, which regulate the burners indefinitely until the set temperature is reached.

Baked to Perfection, Every Time.

An automatic gap detection is available to prevent color differences on the edges of the product and provide a stable bake despite incidental stoppages during the normal flow of production.

The modulating burners consist of a specially rolled and profiled pipe fitted over its entire length with a stainless steel corrugated strip burner bed. Each burner is equipped with an electrically operated double gas valve and an air supply valve, an ignition pin, which also serves as an ionization pin, and a local burner control unit. These control units ensure ignition of the burner, gas valve control, and flame monitoring. The burners are operating following a zero gas pressure system.

Access the Den Boer Tunnel Oven Brochure

Request More Information About the Den Boer Direct-Fired Tunnel Oven

At AMF Den Boer, we’re committed to supporting bakeries around the world with the highest quality equipment to optimize operations, improve product quality, and grow your bakery. Fill out this form to connect with an AMF Den Boer specialist.