Choosing Your Oven System

AMF Bakery Systems has been pioneering the commercial baking industry with the most advanced baking solutions for over a century. Our complete thermal portfolio ensures that we are finding the best baking solution for your production needs. All of AMF’s thermal technologies are part of a complete system solution, ensuring seamless operation from mixer to marketplace. By choosing a complete system, you ensure complete control and visualization of your entire baking process. Our experienced team of bakers and process experts work with you to optimize the efficiency of your line while maintaining the perfect bake and product consistency.

There are several factors to consider when selecting the appropriate oven for your product:

- Product Requirements – Some baked products require heat application at specific stages in the baking process. Other products require moisture control in specific stages of the baking cycle to achieve the best bake. The air flow from the top or bottom of the product along with the stage of the baking cycle will dictate the product’s appearance. Some products, like brioche or hard rolls, require a steam application in the first section of the oven for optimal shine and crust development, which is not available in every oven. Different types of products requiring different baking profiles can be achieved with the correct choice of industrial oven.

- Type of Fuel – Direct-fired tunnel, tray, or continuous ovens are used only if electric, natural gas or LPG, and the products of combustion can be in the baking chamber. If you have any other type of fuel, your bakery will require an indirect-fired oven.

- Available Floor Space – Tray ovens are extremely compact for the capacity. Tunnel ovens are approximately 40% longer than a tray oven for the same capacity but offer the same width as tray ovens. Continuous ovens are similar length as tray ovens, however wider than both tray and tunnel ovens.

- Ceiling Height – Tray ovens are the most compact in height as well as length. Tunnel ovens are taller than tray and continuous ovens always require the most height. In many cases, the size and layout of your facility will dictate which oven is best suited for your bakery depending on height clearance and building column spacing.

- Production Rate – The higher-production lines require greater oven capacity than the largest available tray oven. Tunnel ovens can be extremely long, in excess of 200 feet or 60 meters, for large scale production lines.

Let’s now take a look at the various types of ovens available!

BakeTech Continuous Ovens

With proven performance and unmatched reliability, BakeTech Continuous Oven Systems remain the industry’s best solution to optimize floor space while offering maximum layout flexibility. BakeTech Continuous Ovens are also suitable for a wide range of specialty product applications including buns and rolls, bread, bagels, pastries, cinnamon rolls, and more.

With twice as many burners as competing ovens, BakeTech Continuous Ovens ensure complete zone control with each zone operating independently from the other. Pan tracking in the oven automatically raises or lowers burner output depending on the product flow ensuring the best baking profile.

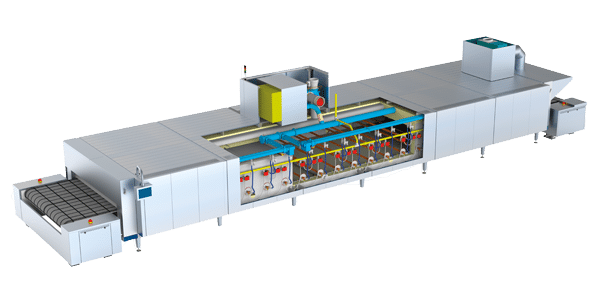

Den Boer Tunnel Ovens

AMF Den Boer Tunnel Ovens are built with modular configurations ensuring easy installation and flexibility as bakers look to grow their product line and production rates. From waffles, croissants, cupcakes, cookies, and more, the Den Boer Tunnel Oven offers maximum versatility with the ability to bake product directly on the oven belt.

The versatile Den Boer Tunnel Ovens are available in four main types of ovens. Multibake® D Direct Fired Ovens are available with gas or electric heat for high temperature baking. Multibake® R Radiant Ovens are best for mono production at the best price to performance ratio. Multibake® I Impingement Ovens are best when space and baking time is limited. Multibake® H Direct/Indirect Oven offers supreme control of your baking parameters ensuring higher baking quality and increased product uniformity.

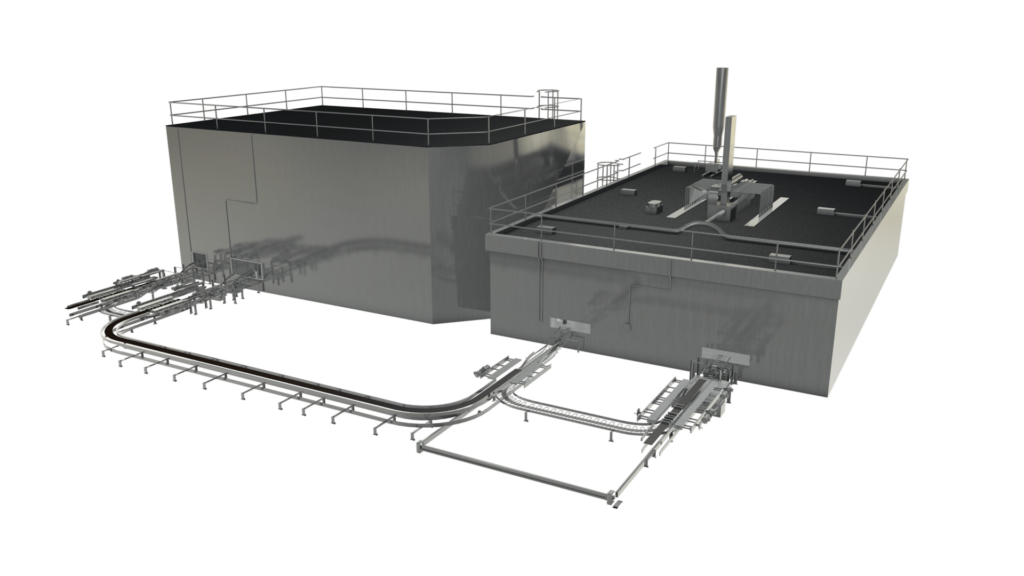

Vesta Tray Ovens

Of AMF’s complete array of thermal technologies, Vesta Tray Ovens are best used for high quality, high-speed production for products requiring longer bake times. These ovens are also great for really dense breads at high rates of production.

AMF’s Vesta Ovens utilize a patented Guardian Chain Management System to ensure equal tension on all three chains preventing jams and significantly extending chain life with predicative lubrication alarms. The exclusive chain design is the most durable chain available due to deeper hardening, higher-precision finishes and stronger alloys.

For the best baking solution for cookies,

Download BRAND BROCHURE

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

"*" indicates required fields

Relevant Resources

-

Maximizing Bakery Output with AMF BakeTech’s Continuous Systems

Enhanced production flow, proven durability, and repeatable quality are key to staying ahead in the competitive world of commercial baking. Large-scale industrial bakeries must continually adapt…

-

Container Handling Solutions With AMF Workhorse Automation

Optimize Bakery Efficiency with AMF Workhorse Container Handling Solutions. Automate your bakery’s post-packaging systems to boost productivity and reduce labor costs. The pressure to reduce labor dependency,…

-

AMF Workhorse Advanced Product Loading Solutions

Boost efficiency, reduce labor demands, and ensure product quality with AMF Workhorse’s advanced product loading solutions. Commercial bakeries face increasing pressure to deliver more with fewer…