Bakery Container Handling

AMF Workhorse’s fully automated container handling equipment provides commercial bakeries with reliable, high-performance solutions that reduce manual labor and improve operational safety. Capable of integrating seamlessly into bakery environment, our container handling technology enhances plant efficiency while minimizing maintenance needs. With servo-driven technology, smooth operation is ensured, along with user-friendly touchscreen displays for easy recipe changes and precise control. The ergonomic design and self-monitoring system tools further enhance productivity, delivering consistent container handling with minimal intervention.

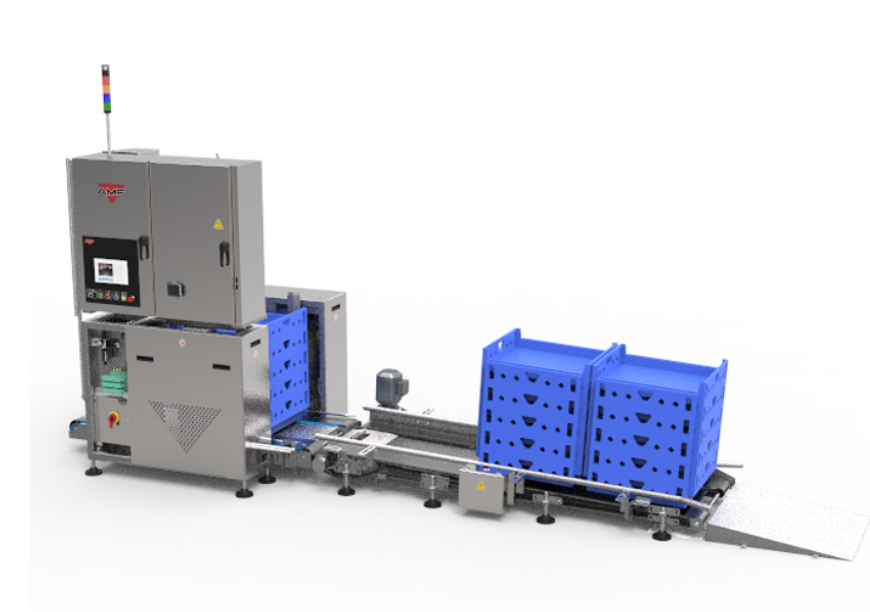

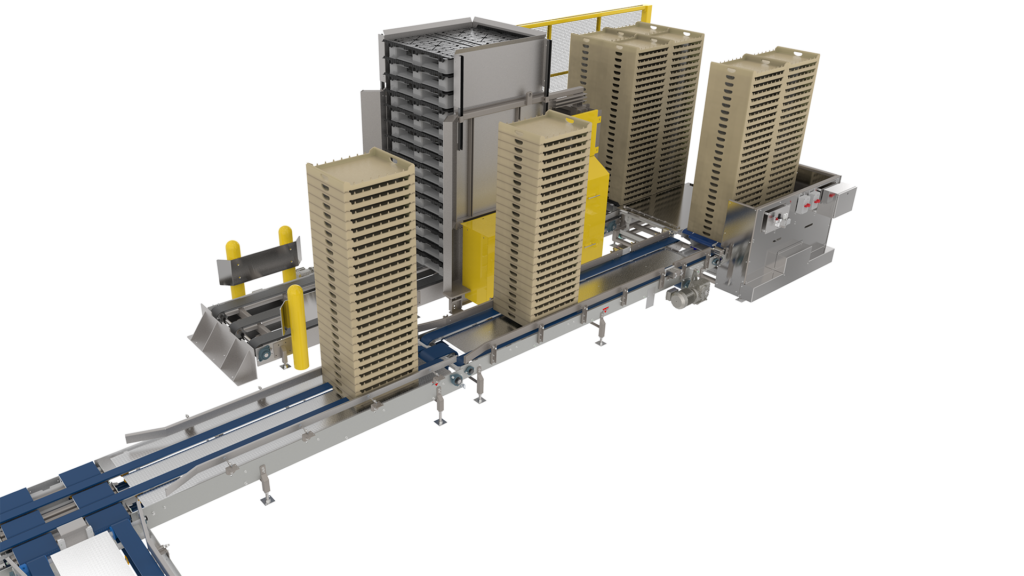

Container Stacking Systems

Fully automated stacking and unstacking technology that forms the foundation of a comprehensive, turnkey solution and ensures smooth, reliable handling of containers.

Bottom-Up Stacker

Engineered for high-speed, precise stacking of containers, ensuring that operations keep moving without unnecessary interruptions.

Bottom-out Unstacker

Accurate, consistent unstacking up to 40 baskets per minute for standard nested or cross-nested baskets.

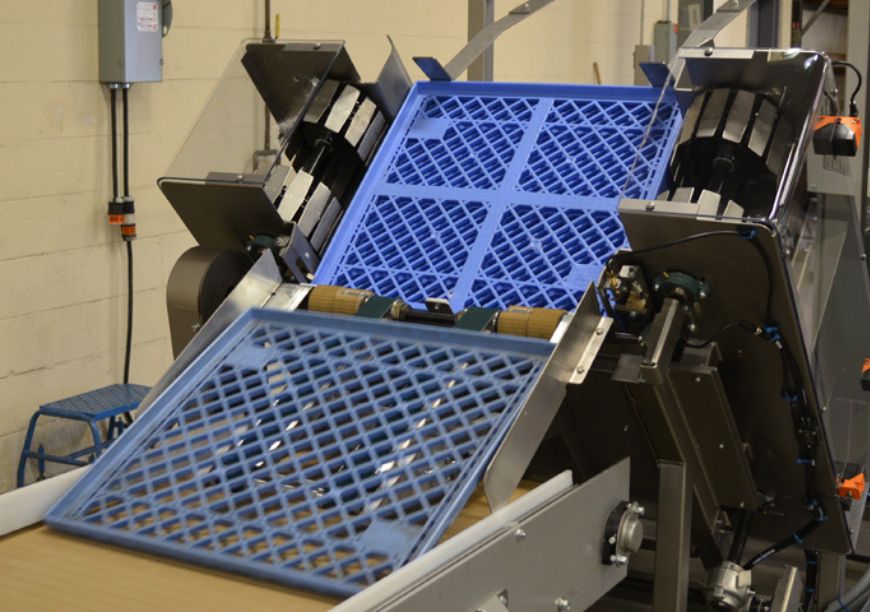

Plastic Tray Unstacker

It automatically unstacks plastic shipping trays to feed product loaders. A self-monitoring system prevents duplicates or damaged trays from entering the system.

Distribution Handling

AMF Workhorse’s distribution handling equipment is designed for the efficient storage and retrieval of post-packaged baked goods in containers, optimizing warehouse operations and ensuring seamless, automated movement from packaging to distribution.

Basket/Container ASRS for Freezer Storage

For products that need to be stored temporarily in freezers, bakeries can integrate an Automated Storage and Retrieval System (ASRS) to handle temporary basket storage before containers are moved back to production or shipping.

Automatic Guided Vehicle (AGV)

Automatic Guided Vehicles (AGVs) take over the task of transporting pallets or containers across the facility, reducing the need for manual intervention.

Dolly Loader

Containers can be loaded directly onto dollies, which can then be manually transported or wheeled to the next phase of production.

Discharge Conveyor to Pallet

Containers can be directed onto a conveyor that discharges them on to a pallet for operators to manually transport to distribution.

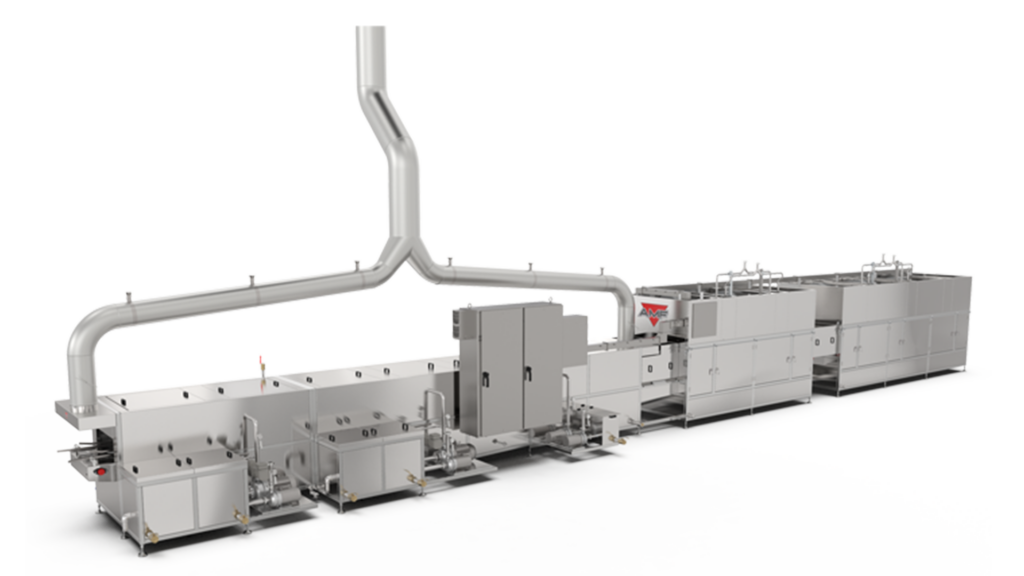

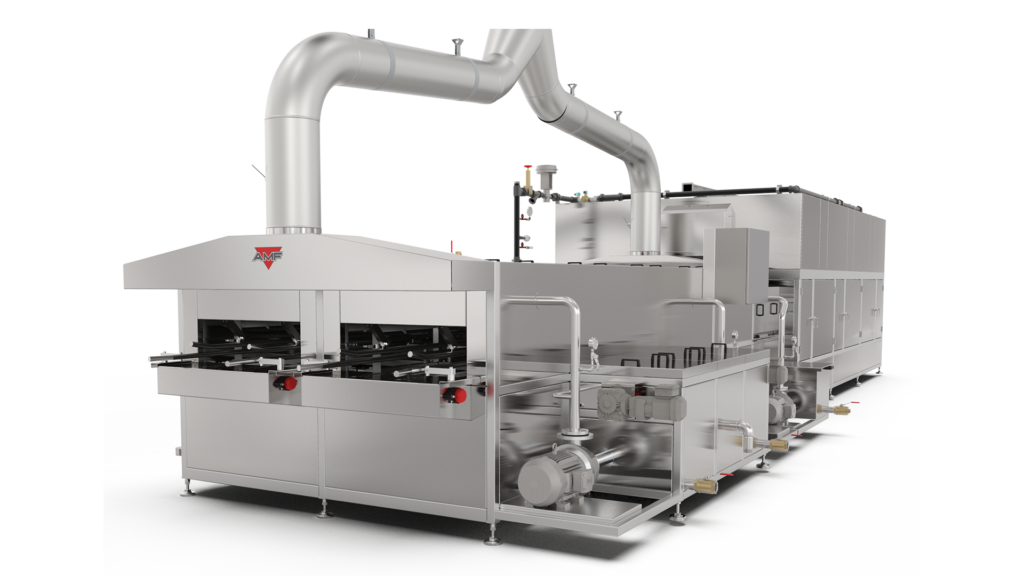

Basket Wash Systems

AMF Workhorse’s basket wash systems are designed to meet the specific needs of your bakery, accommodating various basket sizes and production rates of up to 80 baskets per minute. These flexible systems reduce manual labor and enhance plant safety while ensuring thorough cleaning and drying of baskets for a more efficient post-packaging process.

Single Tunnel Basket Wash System

Ideal for smaller bakeries, the Single Tunnel Basket Washing System offers high-quality cleaning in a compact design, helping you meet hygiene standards without sacrificing valuable production space.

Dual Tunnel Basket Wash System

With dual lanes, this system ensures faster throughput, reducing washing bottlenecks and keeping up with higher production volumes.

Dry Trash Removal System

Offers an effective way to remove dry trash and debris from baskets for optimum washing or stacking in a continuous flow without basket accumulation.

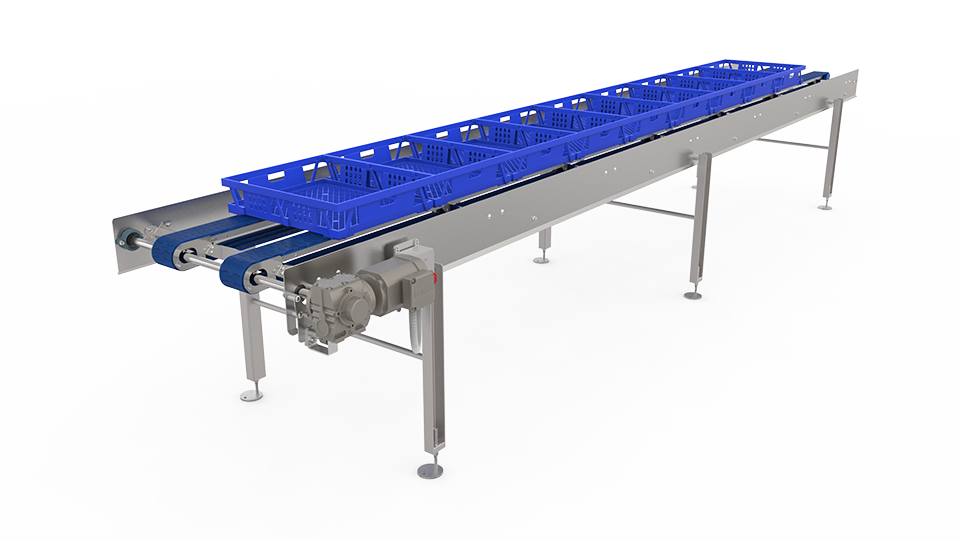

Container Conveyors

A-Series Basket/Case Conveying System

Designed for high operating efficiency and low maintenance, built with anodized aluminum side frames and rust-free materials to move baskets, cases, or trays through downstream processes.

S-Series Basket/case Conveying System

Highest sanitary design to move baskets, cases, or trays seamlessly through downstream processes.

AMF’s Container Handling Brands

Workhorse

Improve line efficiencies and operator safety while eliminating downtime with AMF Workhorse. Our post-packaging solution is your downstream partner that ensures the delivery of your most valuable assets, from pans to packaged products, containers, and more.

Convay

AMF Convay basket conveying systems are fully customizable to seamlessly fit your bakery’s production line, ensuring gentle handling that preserves product quality. Designed for automated operation, they enhance efficiency while protecting the integrity of your baked goods.

Find Your Bakery Container Handling Solution

Use our Bakery Solutions Finder to search for AMF equipment by Products, Processes, & Brands.