Commercial Baking Equipment

AMF BakeTech, Den Boer, and Vesta commercial bakery ovens embody the precision of a master baker combined with the expertise of the industry’s top thermal engineers. With individually programmed temperature zones and controlled air flows, you have more control over your product for the most consistency. AMF’s industrial ovens are designed for optimal heat balance throughout the baking process while improving overall energy efficiency.

Continuous Ovens

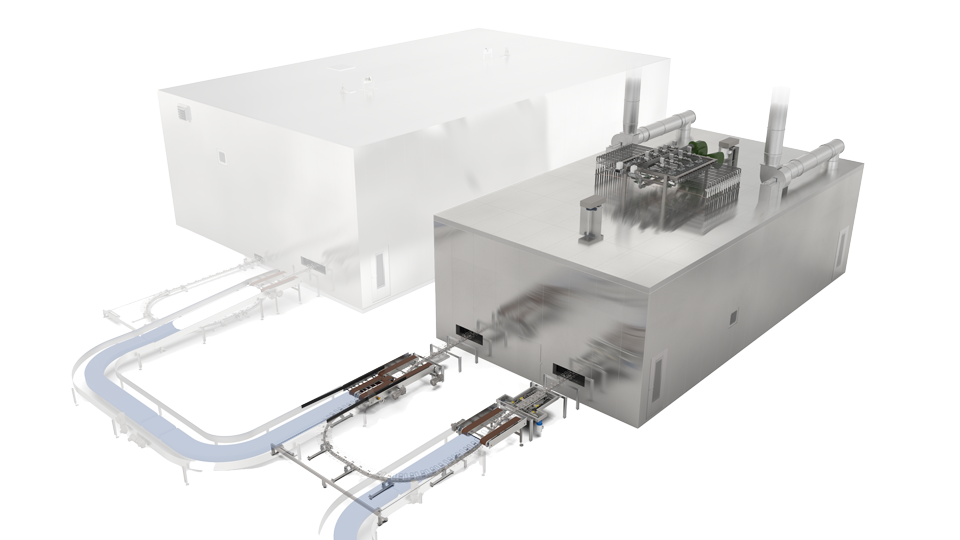

AMF BakeTech’s Continuous Ovens are designed so each pan of product travels one behind the other, exposing products to identical conditions to deliver the most uniformly baked products.

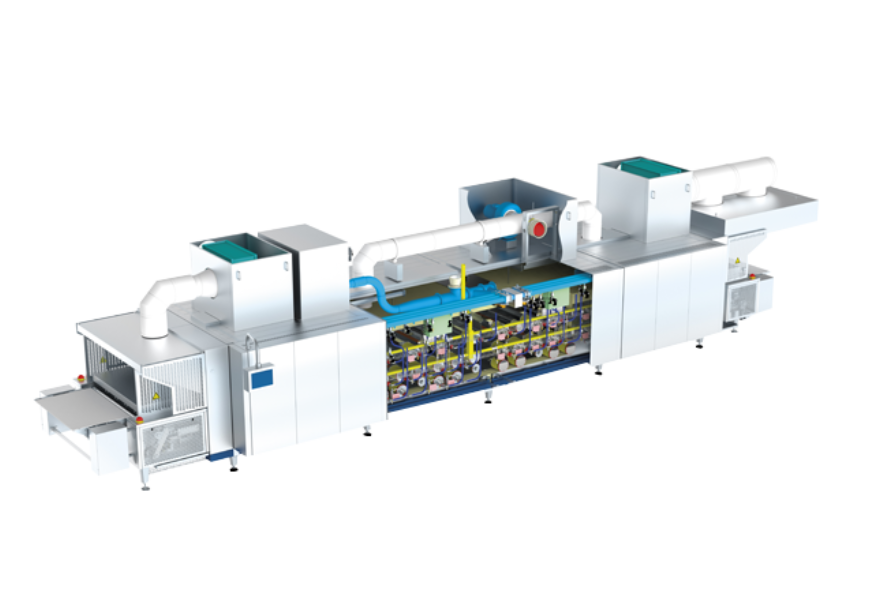

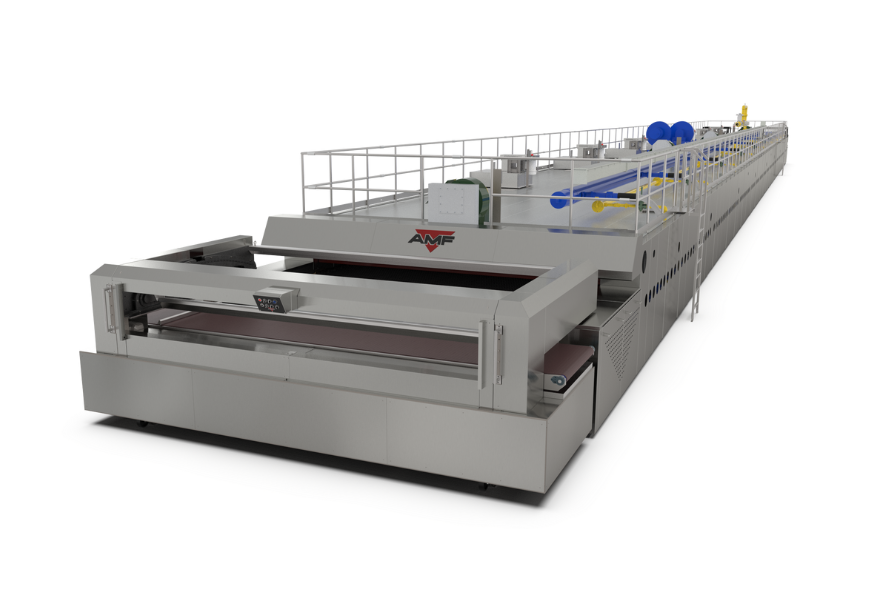

BakeTech Continuous Oven

AMF BakeTech’s Continuous Oven consistently bakes products with year-in, year-out reliability and the most available configurations and radiuses to fit virtually any layout and a range of product applications

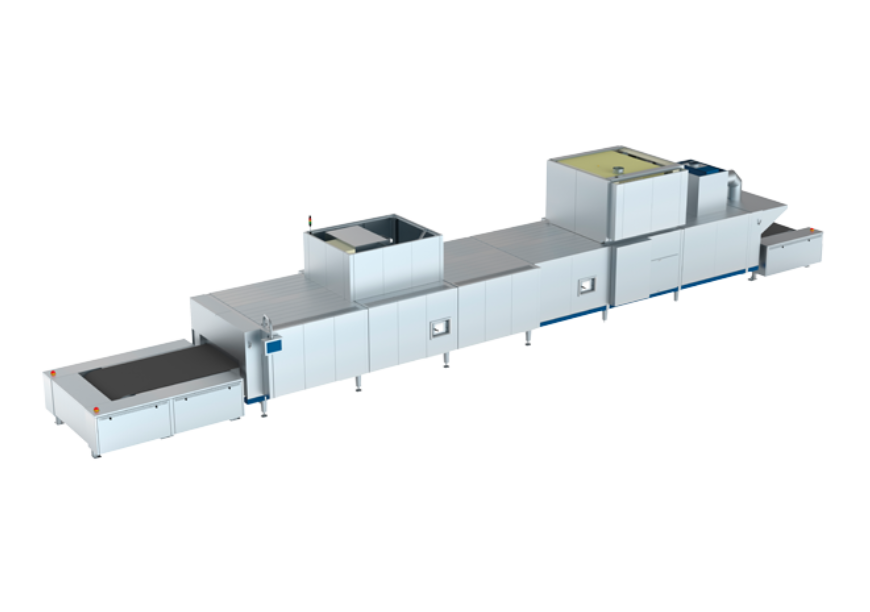

APEX Continuous Oven

Available for emerging consumer markets and designed for bun and roll production, the APEX Continuous Oven has functionality similar to that of the BakeTech Continuous Oven and radiuses to fit many layouts.

Tray Ovens

Maximize your industrial bread baking efficiency with AMF Tray Ovens, achieving precise control over your products for unparalleled consistency. Designed to optimize heat balance throughout the baking process while enhancing overall energy efficiency.

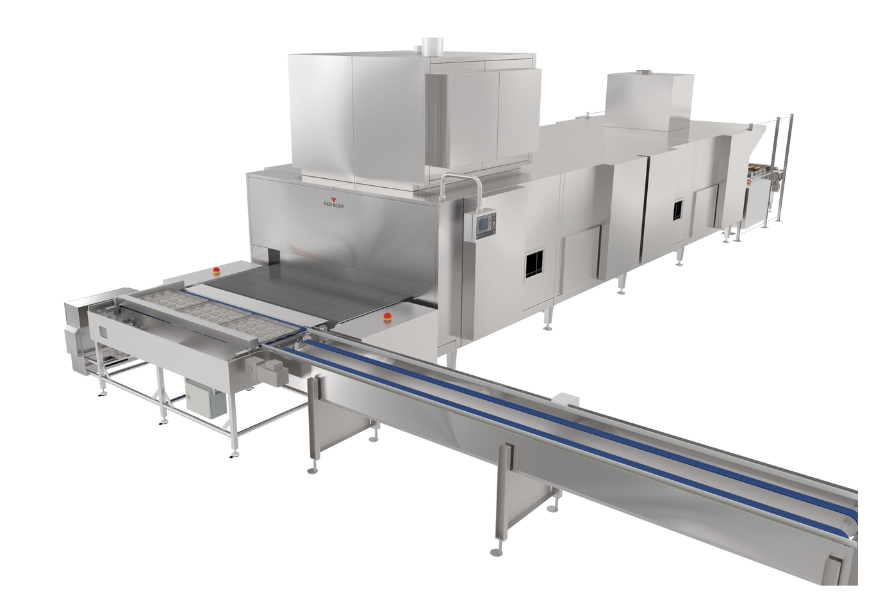

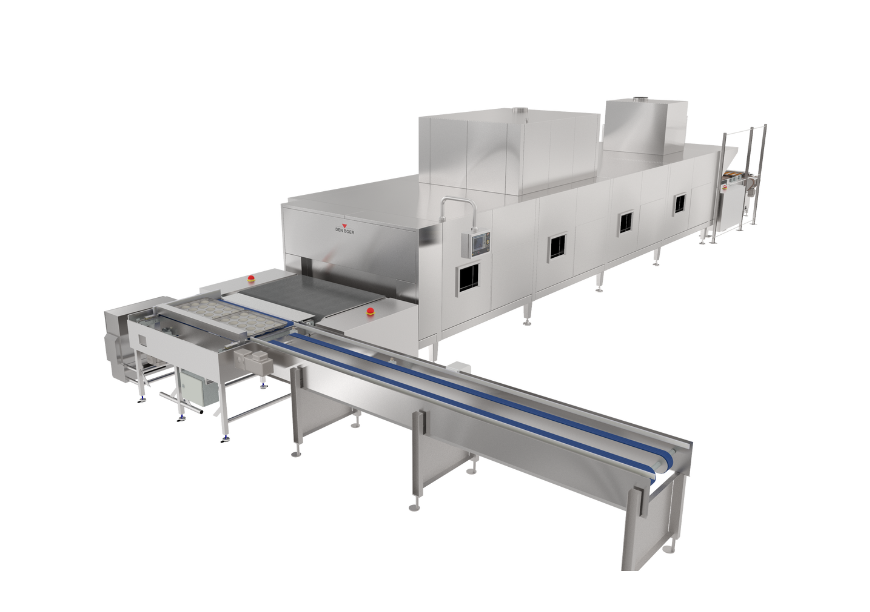

Vesta Tray Oven

The AMF Vesta Tray Oven offers the ideal high-speed, compact solution for quick product changeover. The PLC-controlled baking management system provides independent burner and exhaust control with operator-friendly diagnostics to ensure superior convection for bread and buns, especially those higher in density and requiring longer bake times. Customize your oven to perfectly match the specific needs of your production.

Complementary Equipment

Vesta Tray Oven Loader & Unloader

Our robust design, tailored for tray ovens, ensures side loading and unloading of bread and bun pans with unmatched accuracy and consistency, even at peak production rates.

Tunnel Ovens

Multibake® VITA Tunnel Oven

Introducing the world’s first zero CO2 emission, hydrogen-fueled oven, setting new standards in sustainable baking.

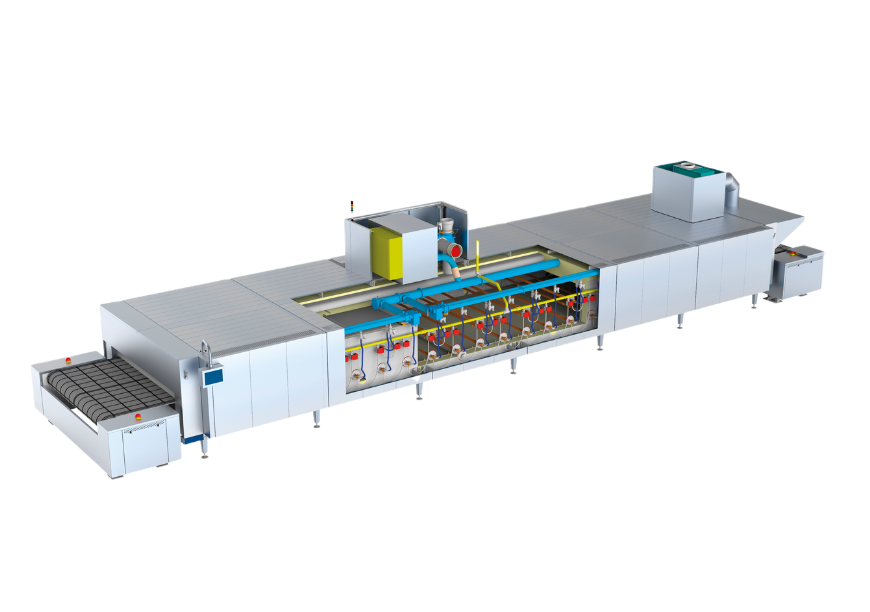

Multibake® Electric Tunnel Oven

The Multibake® E Tunnel Oven is an electrically heated oven for industrial bakeries. It can also be integrated in a hybrid combination with gas-fired modules.

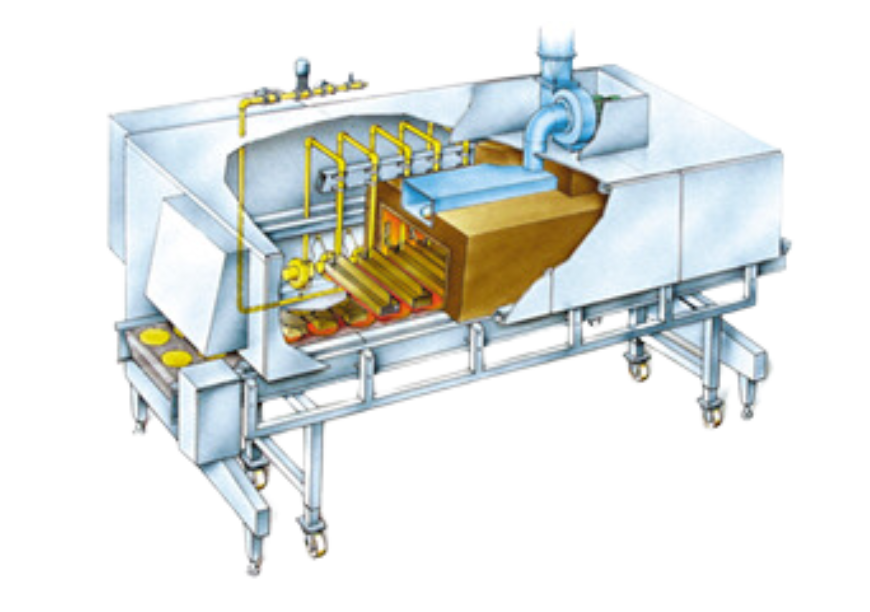

Multibake® Radiant Tunnel Oven

The Multibake® R Tunnel Oven’s heating is entirely indirect, using central burners outside the baking area, which is then transferred to the product using radiator tubes.

Multibake® Direct-Fired Tunnel Oven

The Multibake® D Tunnel Oven requires heat to be created by modulating multi-ribbon gas burners. If you need high temperatures and precise temperature and humidity, this is your solution. Multiple zones are very effective for baking a large variety of bakery products, like breads, buns, bagels, pizza, flatbreads, and more. Direct-fired ovens that apply directly to products are currently the most used oven technology in bakeries.

Multibake® Impingement Tunnel Oven

Multibake® I is an indirect-fired tunnel oven that employs hot air to the upper and lower sides of the product. It is very energy efficient, circulating air to product zones in the oven. The hot air is evenly distributed above and below the products through little nozzles and burner technology. It is very efficient in cake, muffin, and (Danish) pastry production.

Multibake® High-Temperature Tunnel Oven

The Multibake® HT Tunnel Oven is a high-temperature oven for pre-baked products like pizza, flatbreads, and naan. These industrial ovens reach temperatures up to 500 degrees Celsius or 932 Fahrenheit for effective and short high-temperature baking of Arabic bread, pita, pizza, and more.

Multibake® Hybrid Tunnel Oven

The Multibake® H Tunnel Oven is heated using several types of heat transfer combinations, mixing heating technologies for the best baking result. By using two heating technologies in one oven, such as direct-fired gas and hydrogen or electric, your bakery can improve its sustainability.

Multibake® Infrared Tunnel Oven

The Multibake® IR Infrared Tunnel Oven offers toasting, melting, and drying for a variety of products. Very suitable for industrial baking in high temp with products like pizza and flatbreads

Multibake® Dual-Fuel Tunnel Oven

Multibake®R and Multibake®I each have a dual fuel option to minimize downtime and reduce waste. For consistency and optimized oven availability, when one fuel is unavailable, the second one can take over, so the baking process is never disturbed. This option also helps bakeries maximize efficiencies with dynamic pricing in energy contracts.

APEX Series Tunnel Oven

Simple, modular direct-fired tunnel oven design offering maximum profitability and flexibility with independent zone control for precise temperature control for bun and roll products.

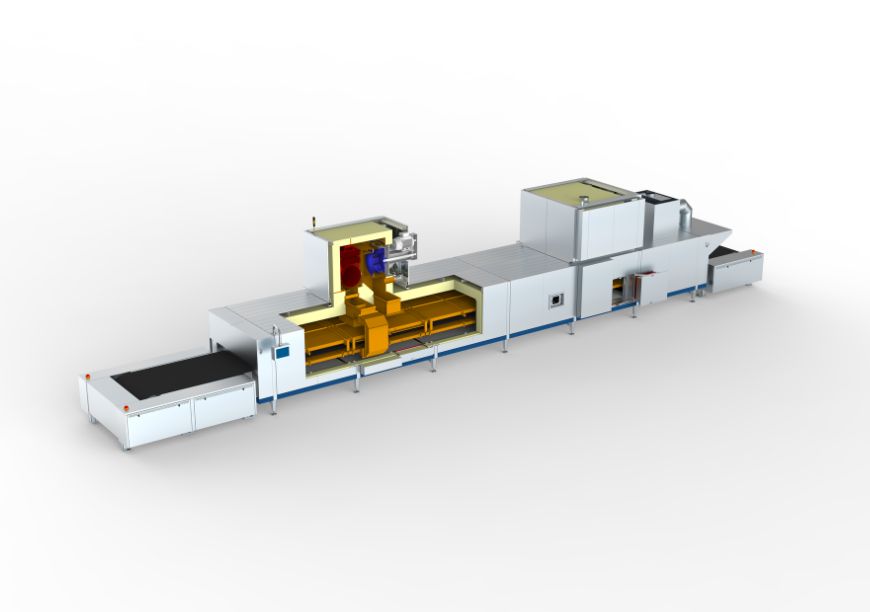

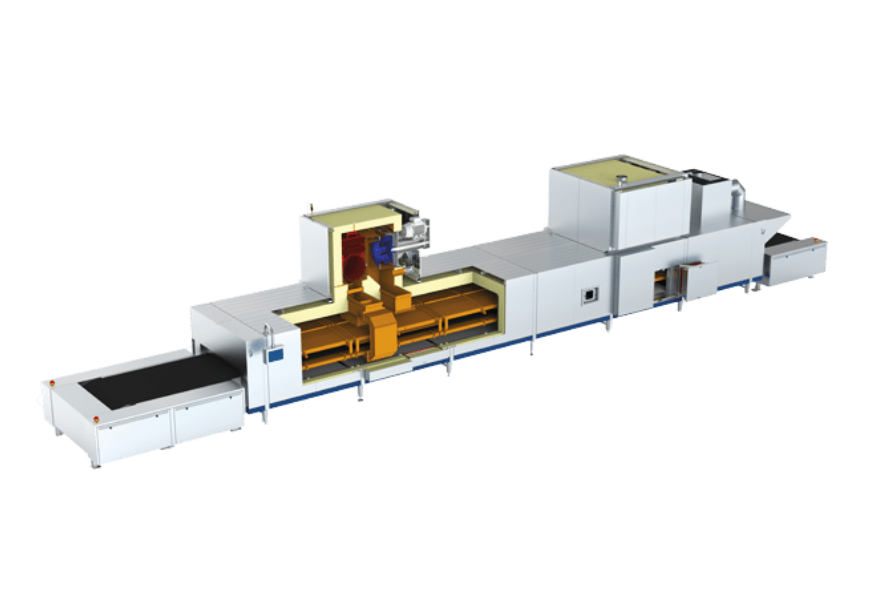

Vesta Direct-Fired Tunnel Oven

AMF Vesta Tunnel Oven offers the ideal straight-line, high-speed baking solution for quick product changeover. PLC-controlled baking management system provides independent burner control and exhaust control with operator-friendly diagnostics to ensure superior convection for bread and buns, especially those higher in density and requiring longer bake times. Customize your oven to perfectly match the specific needs of your production.

Complementary Equipment

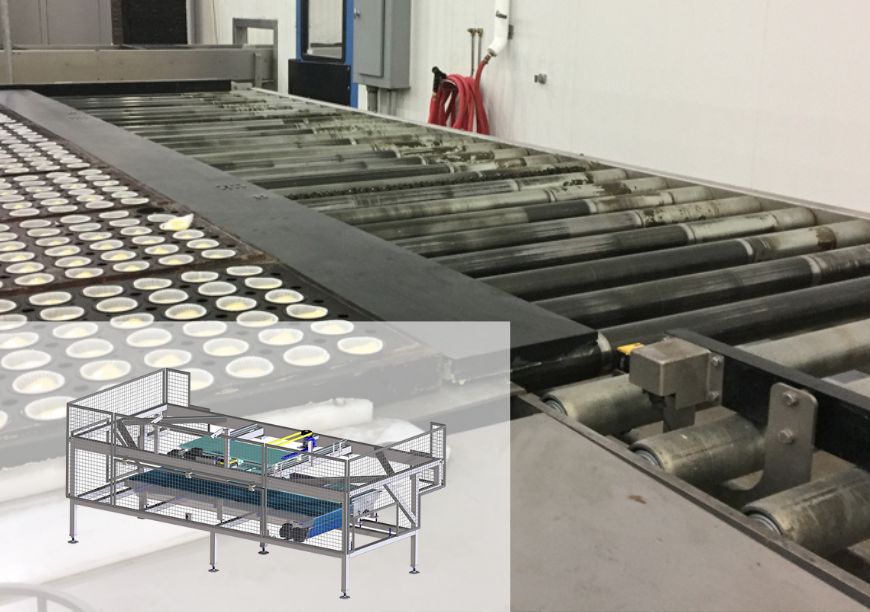

Den Boer Tunnel Oven Loader & Unloader

Streamline the oven loading and unloading process with this system, which has proven performance and reliable integration into your baking process. Trouble-free industrial oven loading for pans, trays, tins, and free-form products.

Vesta Tunnel Oven Loader & Unloader

Precision meets efficiency with our robust design for loading and unloading bread and bun pans in a single line with accuracy and consistency at high production rates.

Griddles

English Muffin Proofer & Griddle

Servo-driven walk-in proofer ensures the easiest sanitation and maintenance. The product is directly transferred from the proofer to a fully insulated Griddle.

AMF’s Commercial Oven Brands

BakeTech

AMF Baketech brings the efficiency, scalability, and consistent quality necessary for many large-scale industrial bakeries. Our continuous proofer and oven systems are leveraged to scale bakery operations and satisfy an ever-evolving market.

Vesta

AMF Vesta combines durability with innovation, making production changeovers effortless. Our custom-configured systems offer seamless solutions for product proofing, baking, cooling, and freezing in a continuous flow.

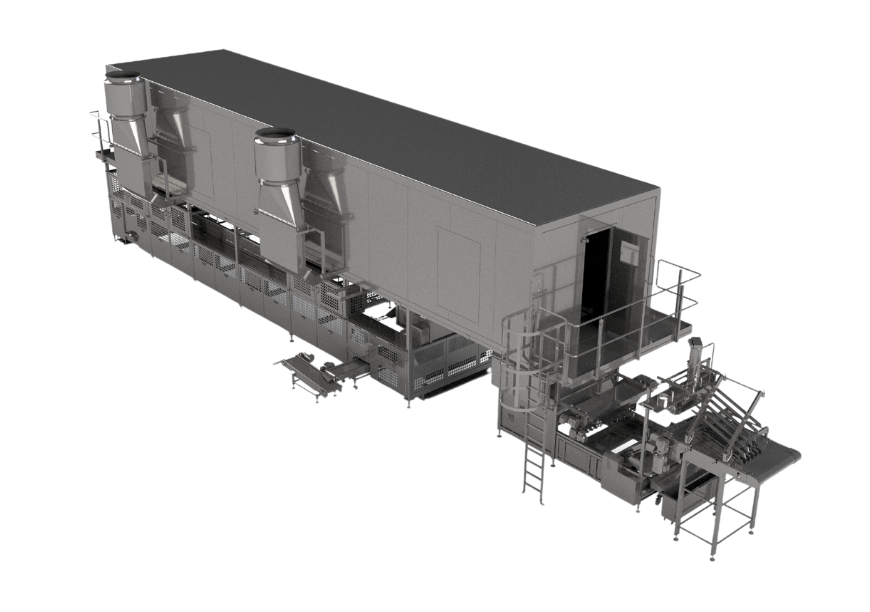

Den Boer

The most striking aspect of the Den Boer Tunnel Oven is its modular design. Modular ovens ensure flexibility as you grow your product portfolio. The pre-assembled modules enable quick turnaround time with more efficient installation.

Product Applications

Download the AMF Baking Technologies BROCHURE

"*" indicates required fields

Find Your Commercial Baking System Solution

Use our Bakery Solutions Finder to search for AMF equipment by Products, Processes, & Brands.