Automation and Optimization For Pizza Production

Experts predict the global pizza market will reach $233.26B by 2027, growing at a CAGR of 11.6% from 2020 to 2027. As one of the most popular food items worldwide, the outlook for the pizza industry only continues to strengthen thanks to the rise in demand for home delivery services originating from the COVID-19 pandemic, an increase in fast casual pizza restaurants, and the adoption of technology like mobile apps and online ordering systems.

However, commercial pizza producers need help with post-packaging processes such as product loading, conveying, and palletizing.

Some of the most common automation challenges pizza bakers may encounter are the following:

- The complexity associated with integrating new systems or unit technologies

- Specialized operator training

- Regular maintenance and repair

- Product variability and equipment customization to accommodate a wide or growing range of products

AMF Workhorse, an AMF Bakery Systems brand, engineers seamlessly integrated, complete post-packaging solutions for a wide range of pizza and flatbread products so that bakers can streamline operations, reduce labor costs, minimize downtime, and improve overall efficiency. Read more to explore the benefits and possible solutions for your pizza post-packaging process.

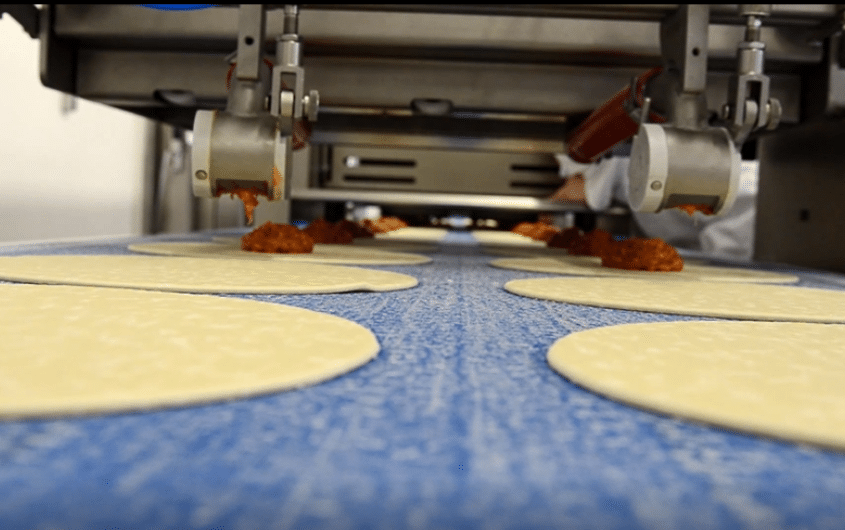

Product Loading

Product loading is a critical step in the post-packaging process. Designed with gentle product handling and layout flexibility, AMF’s product loading systems can be easily integrated into your current bakery processes or combined with AMF’s complete conveying and handling systems to achieve the most efficient post-packaging operation.

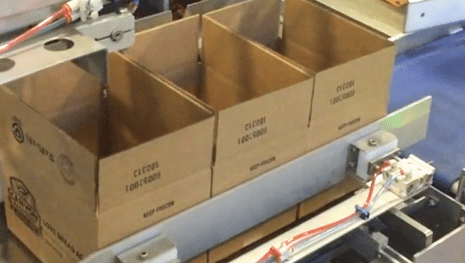

The ABL Case Loader handles various plastic, corrugate, and other container loading applications with high-speed pick and place capability, including U-board insertion. The ABL is equipped with an interchangeable, patented end-of-arm tool designed for specific product applications to gently compress packages into corrugate or other containers for a tight ratio. Recipe management software stores pattern configurations to accommodate multiple package patterns without a tool change, ensuring precise package placement and maximum reliability.

Conveying

Transferring products from one point to another can be challenging when dealing with heavy loads or delicate products. AMF Convay, an AMF Bakery Systems brand, engineers full Conveying System solutions to help transport pizza products, cases, baskets, or pallets quickly and safely.

AMF Workhorse has also developed Automated Storage and Retrieval Systems (ASRS) that deliver custom-configured, intuitive basket and case handling with or without freezer application.

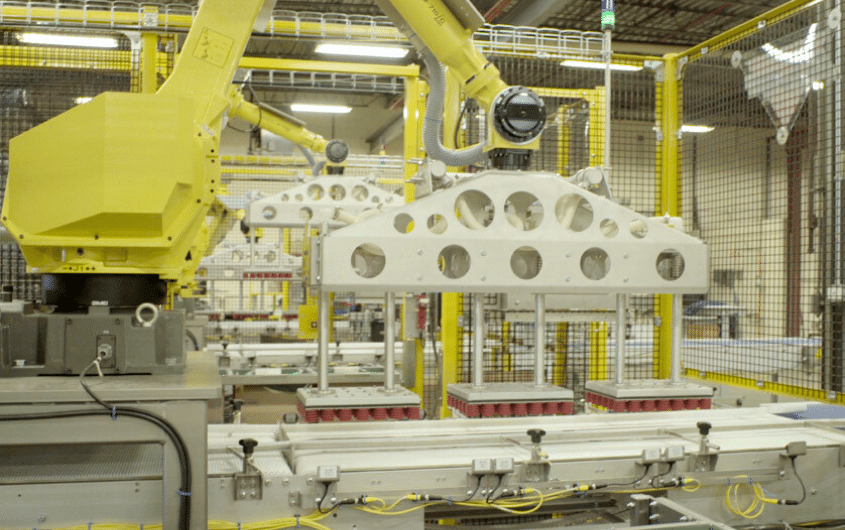

Palletizing Advancements in AMF’s palletizing solutions have improved the reliability and precision of post-packaging processes. Accurate and consistent pallet loading suited for a wide variety of baskets, cases, and pallets ensures maximum reliability for multiple loading patterns.

Delivering accuracy and consistency, AMF’s Robotic Palletizer loads single or multiple sealed boxes or bags onto plastic or wood pallets with several pre-programmed pattern configurations to reduce labor costs and improve operator safety. As an alternative, AMF’s Palletizer receives individual pallets and basket stacks to deliver a fully loaded pallet.

The post-packaging needs of pizza makers vary greatly depending on their product mix, throughput, bakery layout, and distribution method. Therefore, researching the full range of post-packaging options can make considerable differences in quality and cost over time. AMF Workhorse solutions are engineered for gentle product handling through downstream operations to ensure premium post-packaging quality for safe and efficient delivery of all your pizza or flatbreads products.

By delivering this fully-integrated post-packaging system, AMF Workhorse solves a range of the challenges pizza producers might face when scaling operations:

- Reduced Complexity

- A single project manager reduces the risk of miscommunication and project delays. Without having to communicate between multiple suppliers, AMF Workhorse ensures all units work together seamlessly while reducing your lead times for delivery and installation.

- On Demand Training

- With AMF Workhorse solutions, bakery teams have access to premium AMFMethod documentation and training tools empowering your teams and reducing employee turnover while providing easy access to on-demand training for tomorrow’s bakery operators.

- Rapid Customer Care

- As an AMF customer, you receive the unparalleled service and support that the AMF brand is known for to ensure the enduring success of your bakery. With localized backing globally, our teams are already in your region, rapidly responding to customer needs. Anytime. Anywhere.

- Customized Solutions

- Serving a wide range of bakery customers, from bread and rolls to pizzas, cakes, pies, pastries, and more, AMF Workhorse engineers custom-configured solutions for every bakery and application to ensure the most optimal solution.

Ready to automate and optimize your pizza production? Contact the AMF team today to discuss your current pizza project. Streamline your operations and enhance efficiency with our complete post-packaging solutions.

Download the Pizza Production Systems BROCHURE

"*" indicates required fields

Related Resources

-

Beyond Soft Bread and Bun Products

Renowned for its best-in-class make-up solutions, AMF Flex, an AMF Bakery Systems brand, stands out as a beacon of innovation and reliability. AMF Flex technology ensures high-capacity…

-

LaRosa’s Bakery’s Journey with AMF Bakery Systems

LaRosa’s Bakery, a family-owned establishment dating back to 1954, has evolved from a single pizzeria into a well-known chain with 65 outlets across the greater Cincinnati…

-

Celebrating Success at IBA 2023 – A Global Gathering of Bakers and Innovators

We express our sincere gratitude for the remarkable success of IBA 2023. This event was held at the Trade Fair in Munich from October 22nd to…