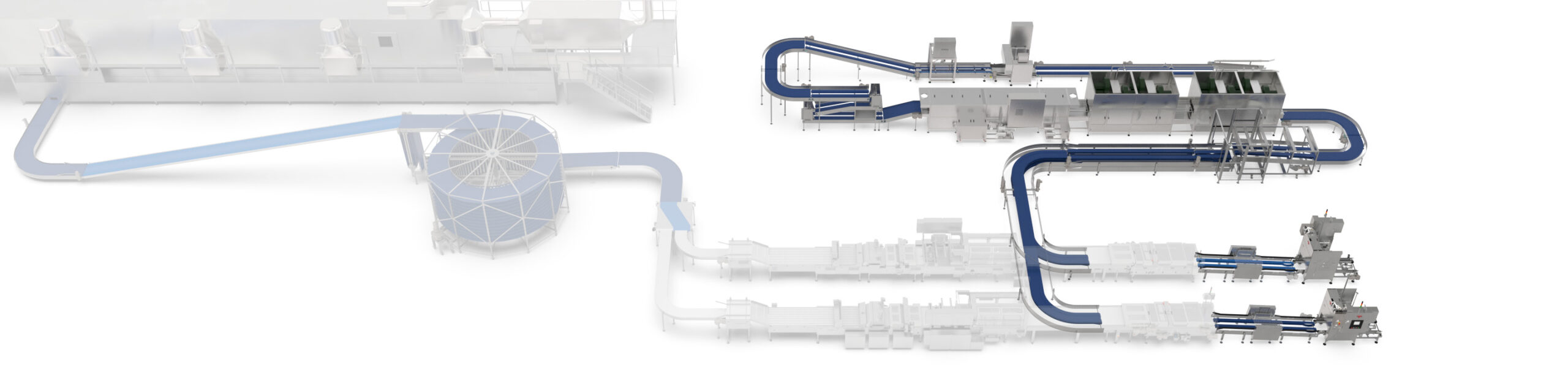

High-Speed English Muffin System

Product Applications

Explore the Bun & Roll System

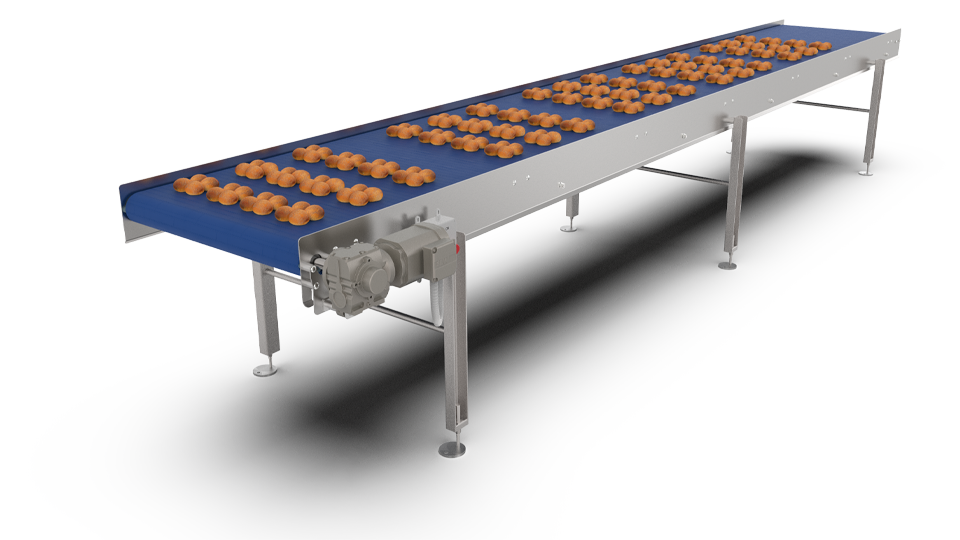

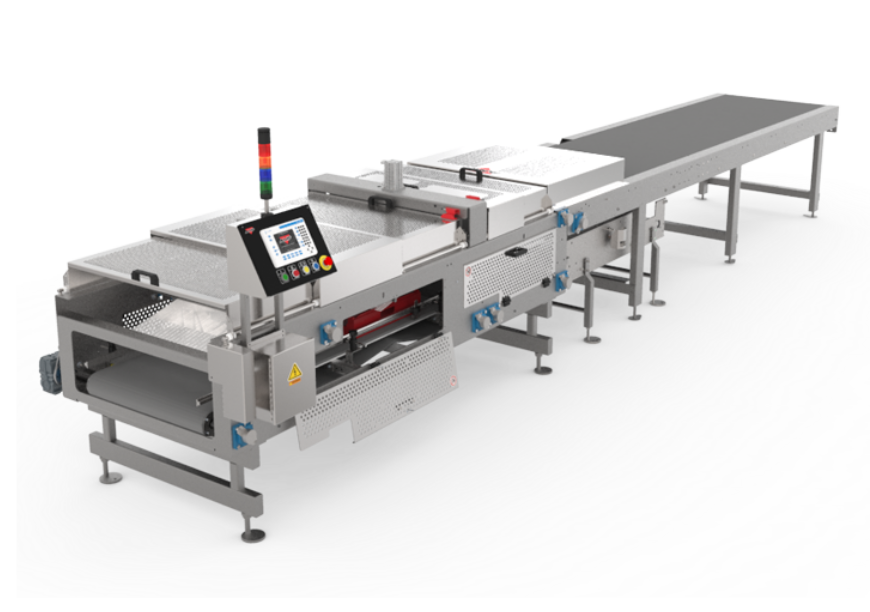

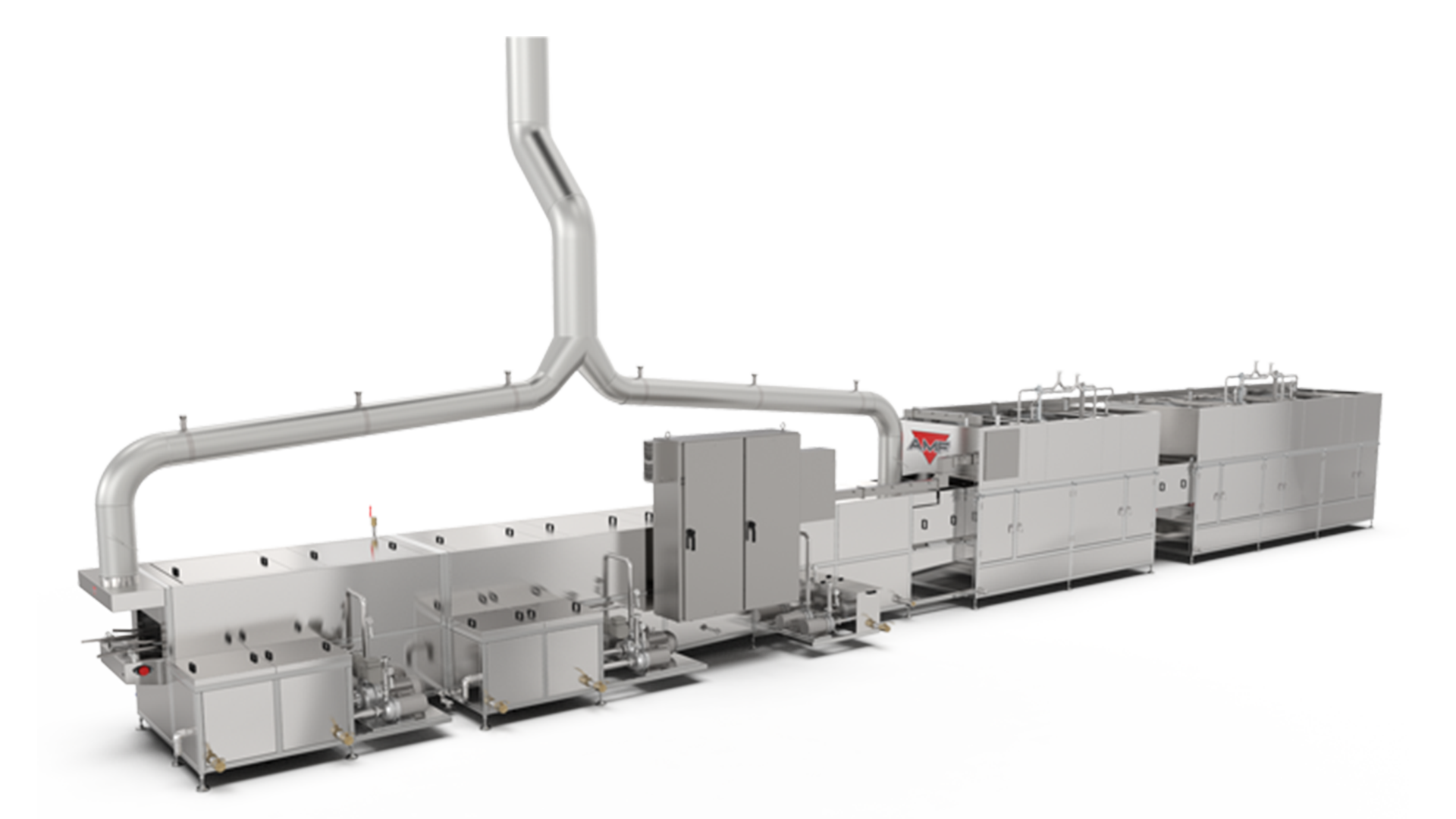

Make-up

Make-up

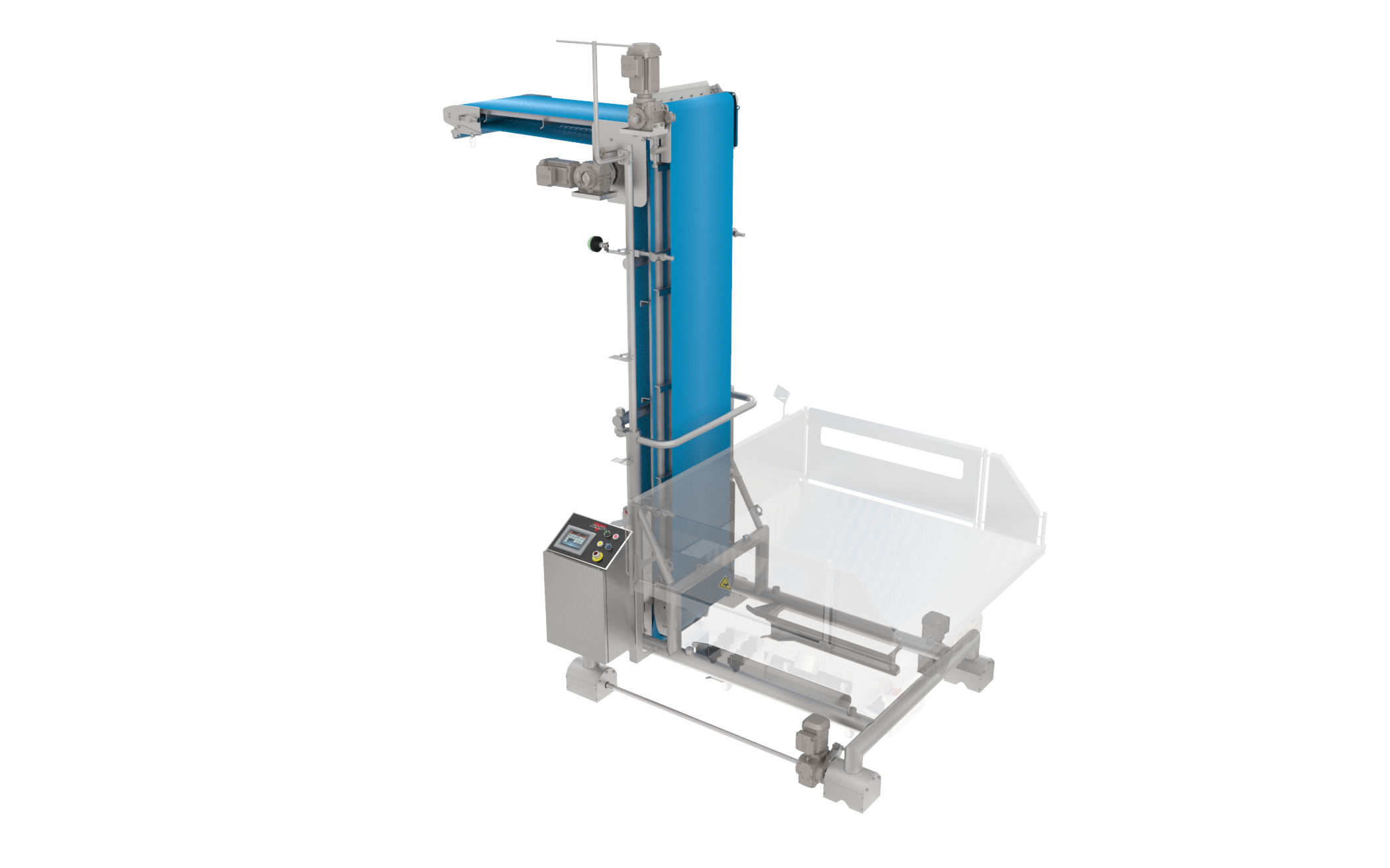

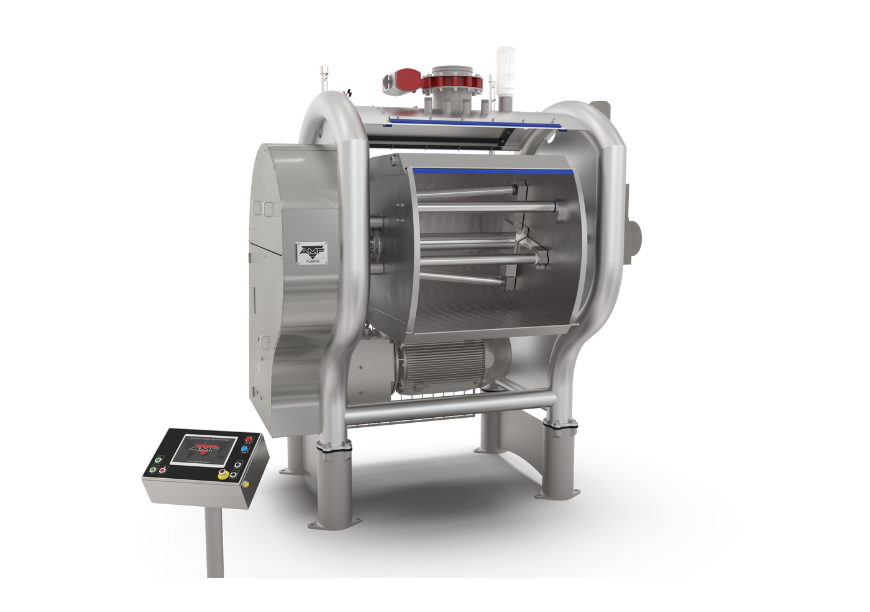

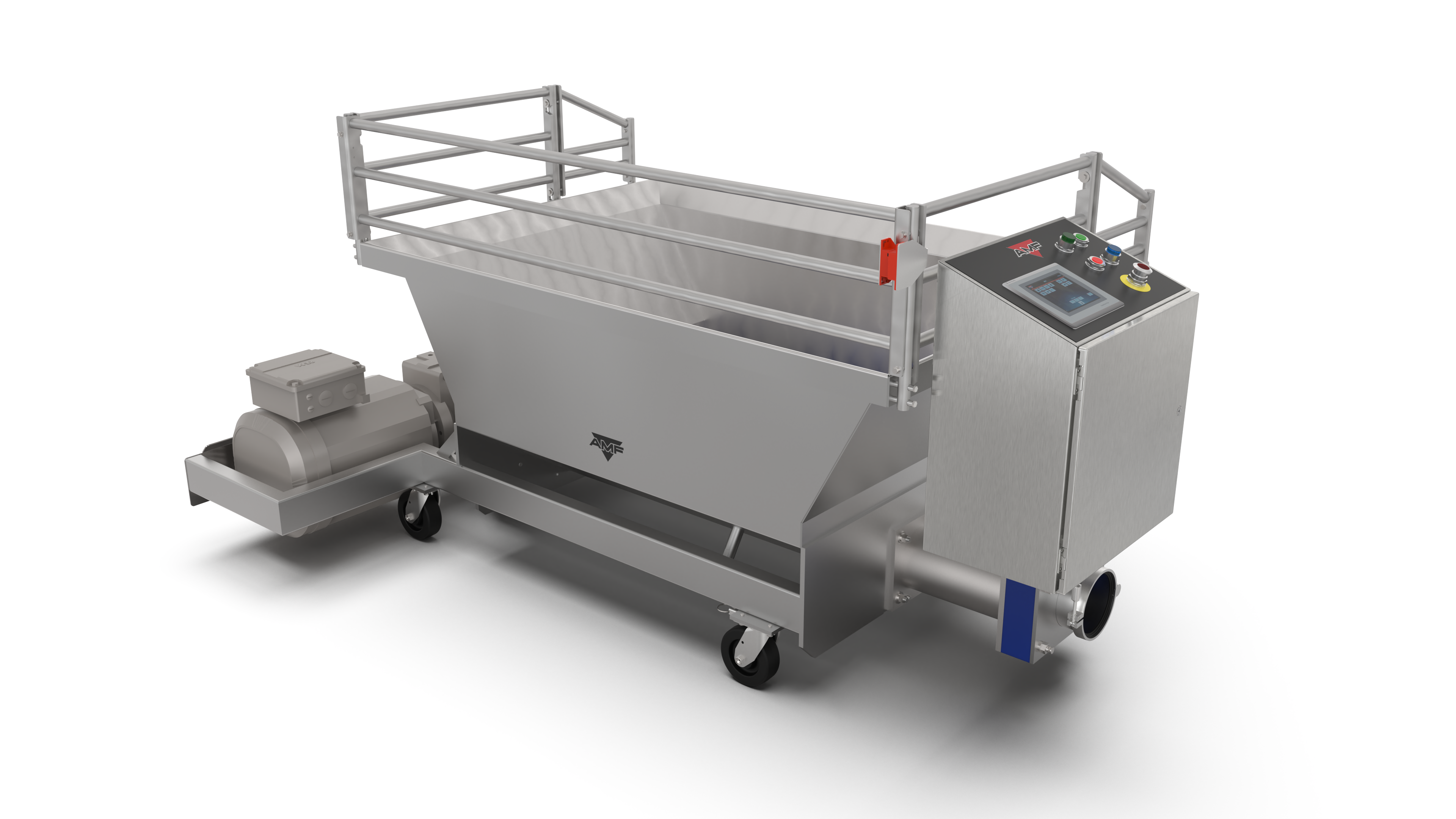

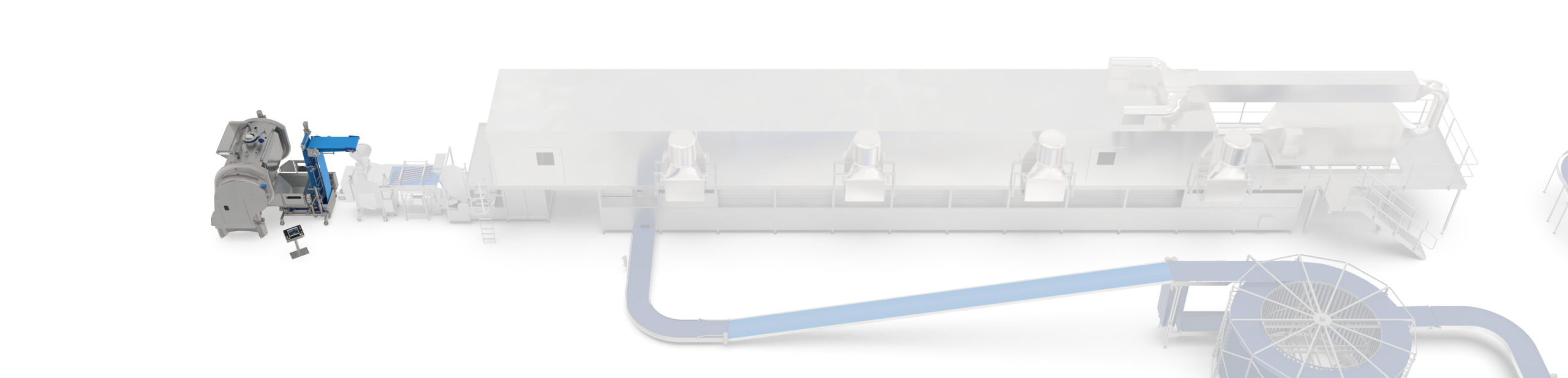

Mixing & Dough Handling

Mixing & Dough Handling

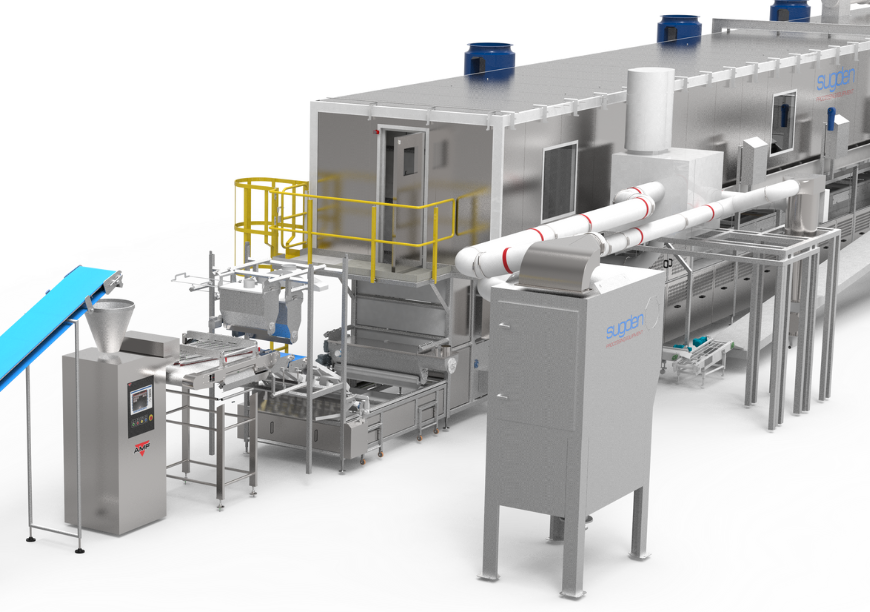

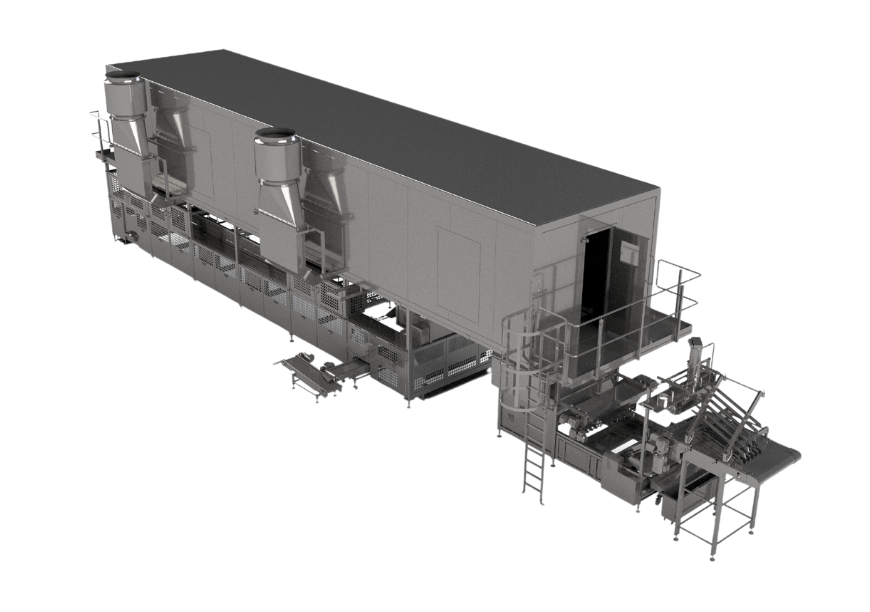

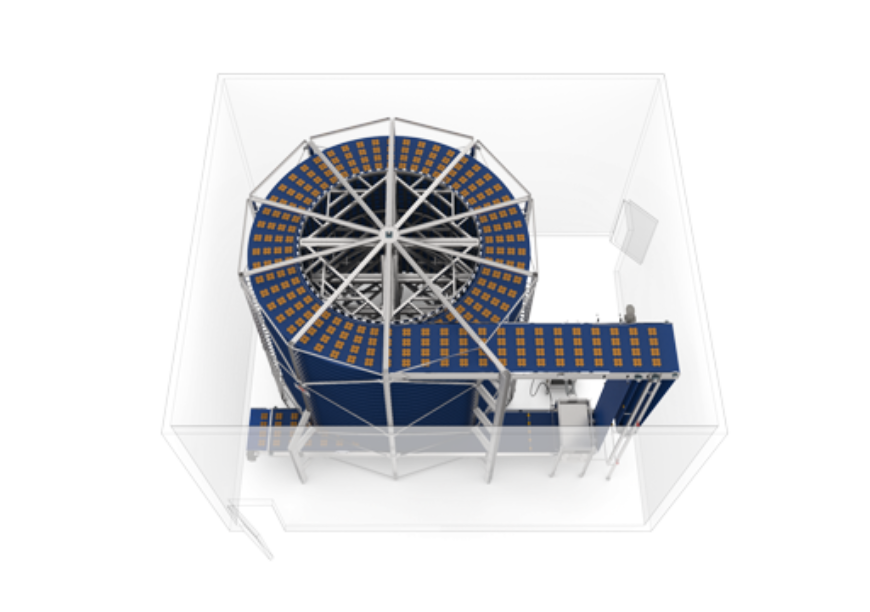

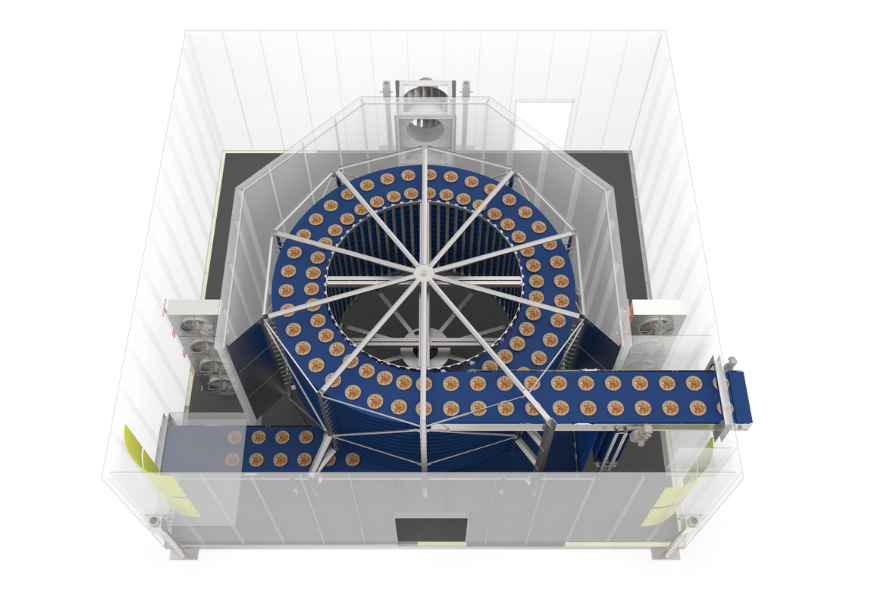

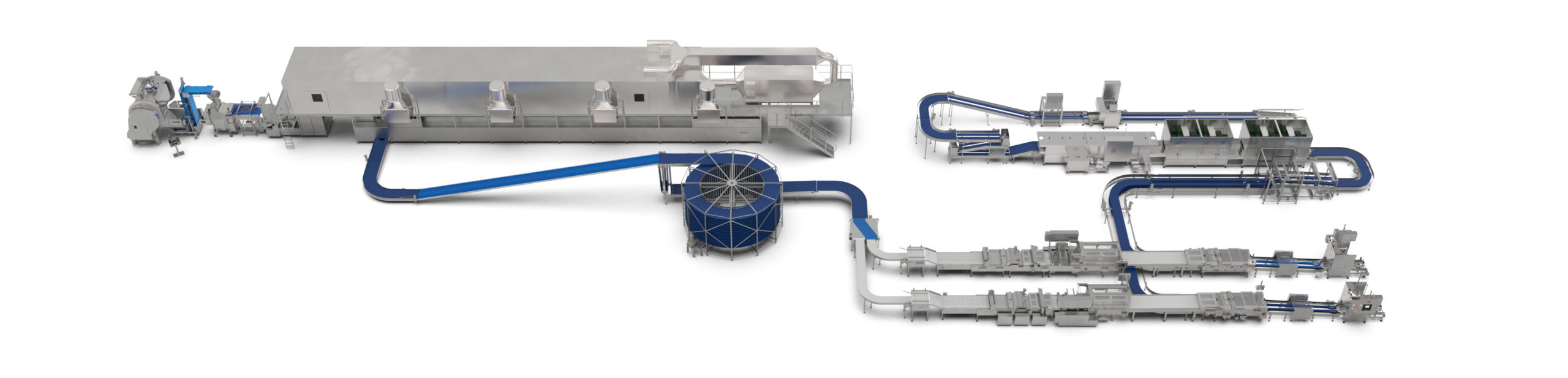

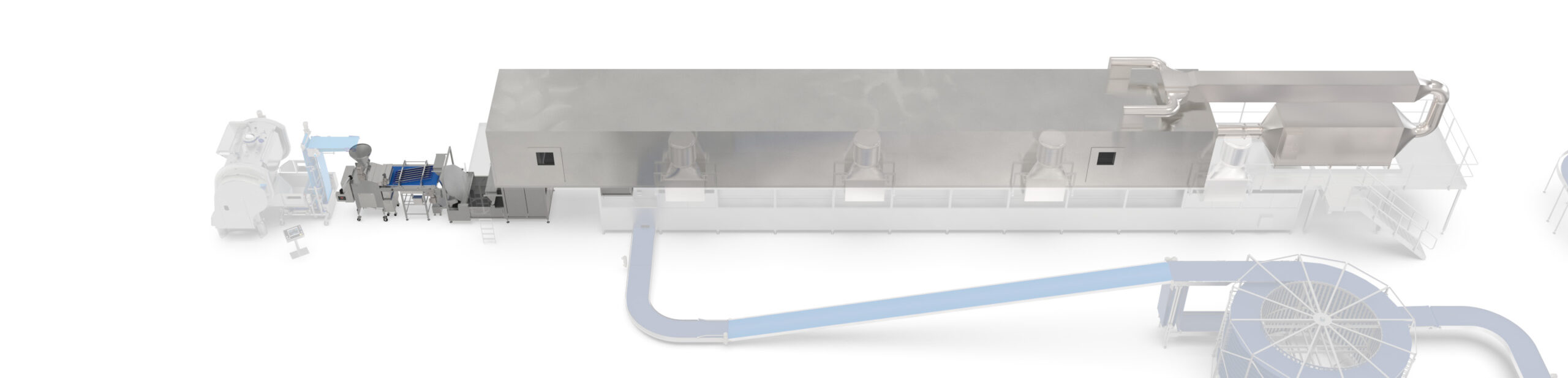

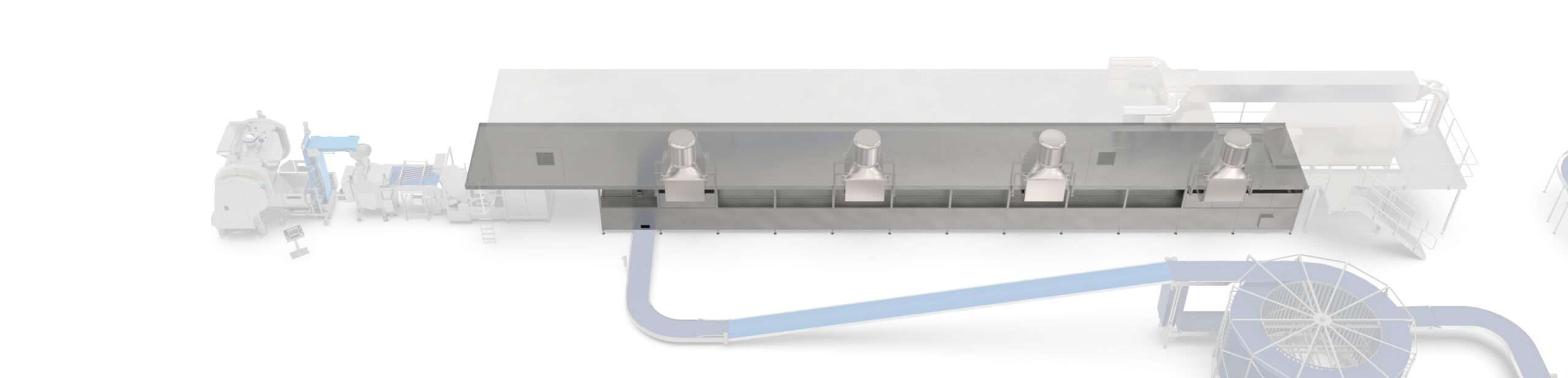

Proofing and Baking

Proofing and Baking

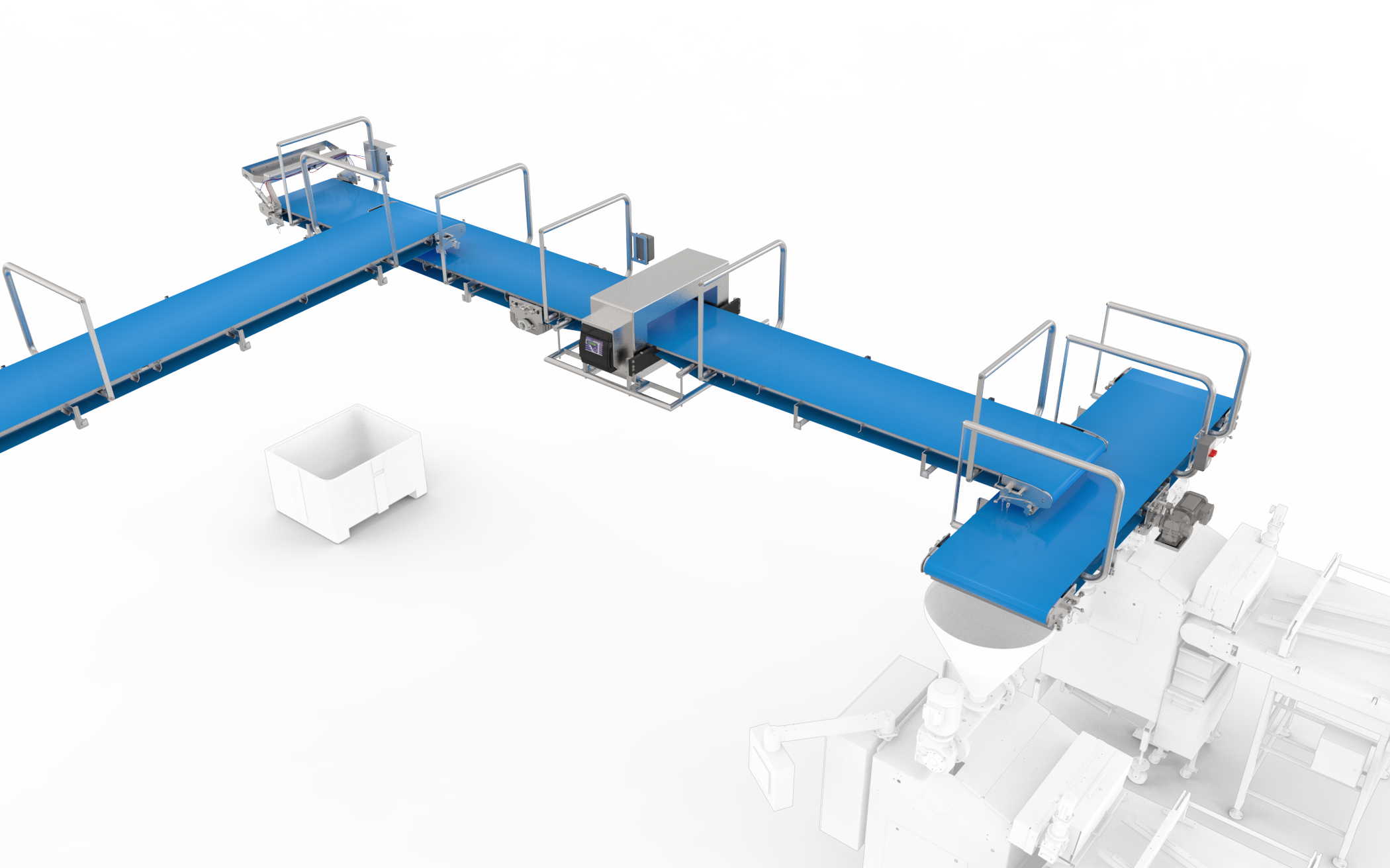

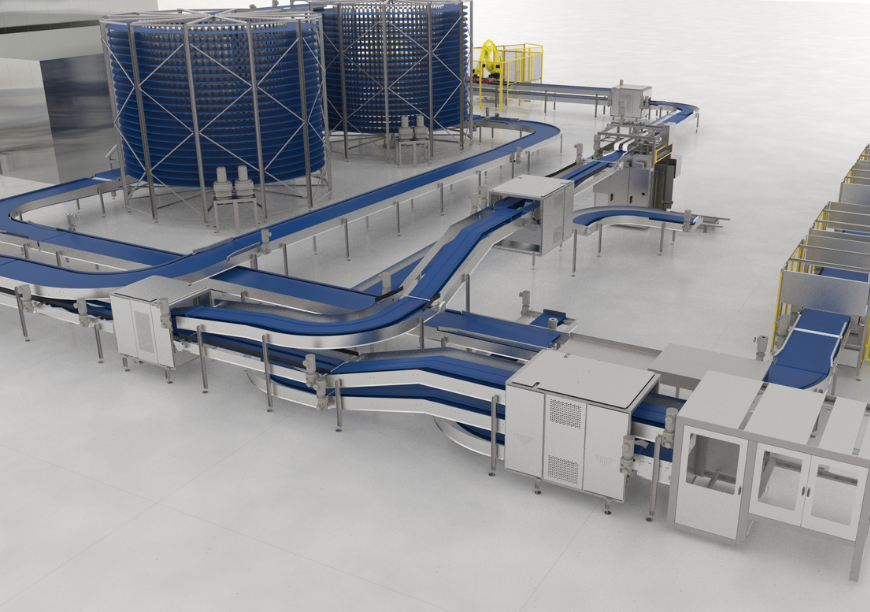

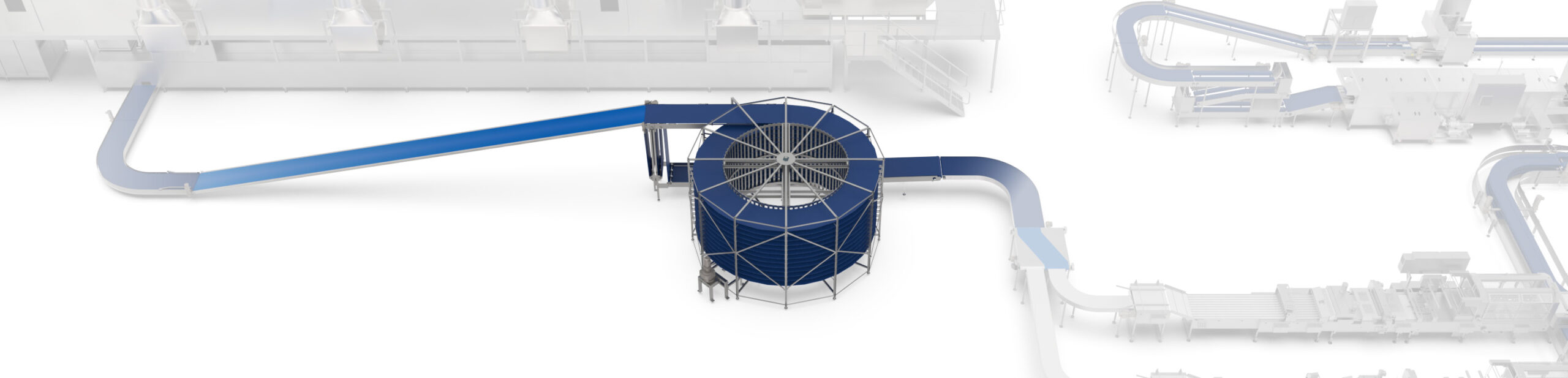

Cooling & Conveying

Cooling & Conveying

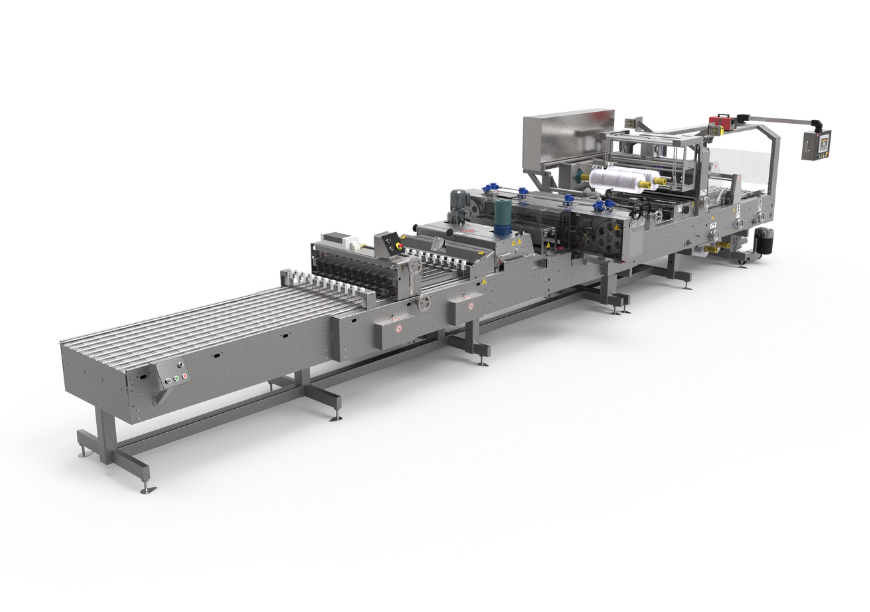

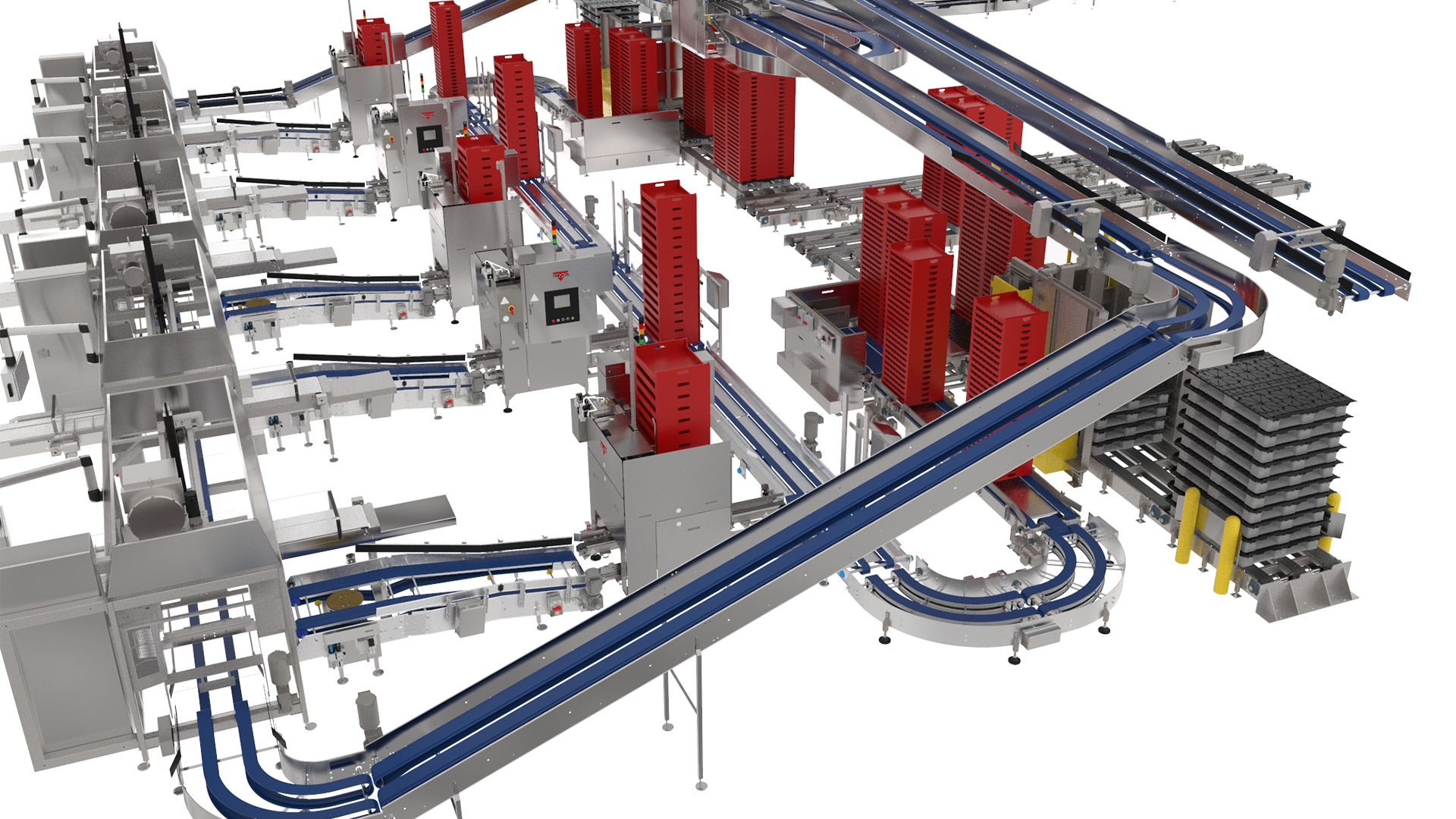

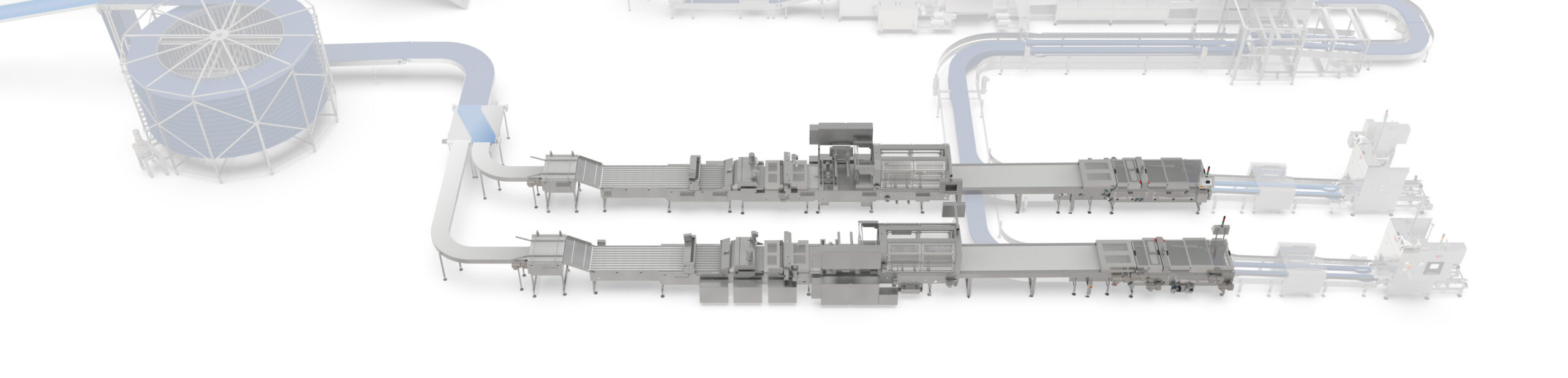

Packaging

Packaging

Post-Packaging

Post-Packaging

Click on a process area to view the recommended unit equipment below

Click on a process area to view the recommended unit equipment below

Process

Make-Up

Mixing & Dough Handling

Proofing & Baking

Cooling & Conveying

Packaging

Post-Packaging

19