Equipment Specifications

| Buns | Breads | |

|---|---|---|

| Dough Piece Size Throughput Kg/Hour Kg/Hour (Flex 1 Option) Kg/Hour (Flex 2 Option) | 35 – 100 grams 20-60 cpm (cuts per minute) 2400 – 7200 pieces per hour 84 720 2,250 | 150 – 1000 grams 10-30 cpm 600 – 1800 pieces per hour 90 720 2,250 |

Additional Media

Visit Our innovation centers

More APEX Solutions for Bread & Bun Production

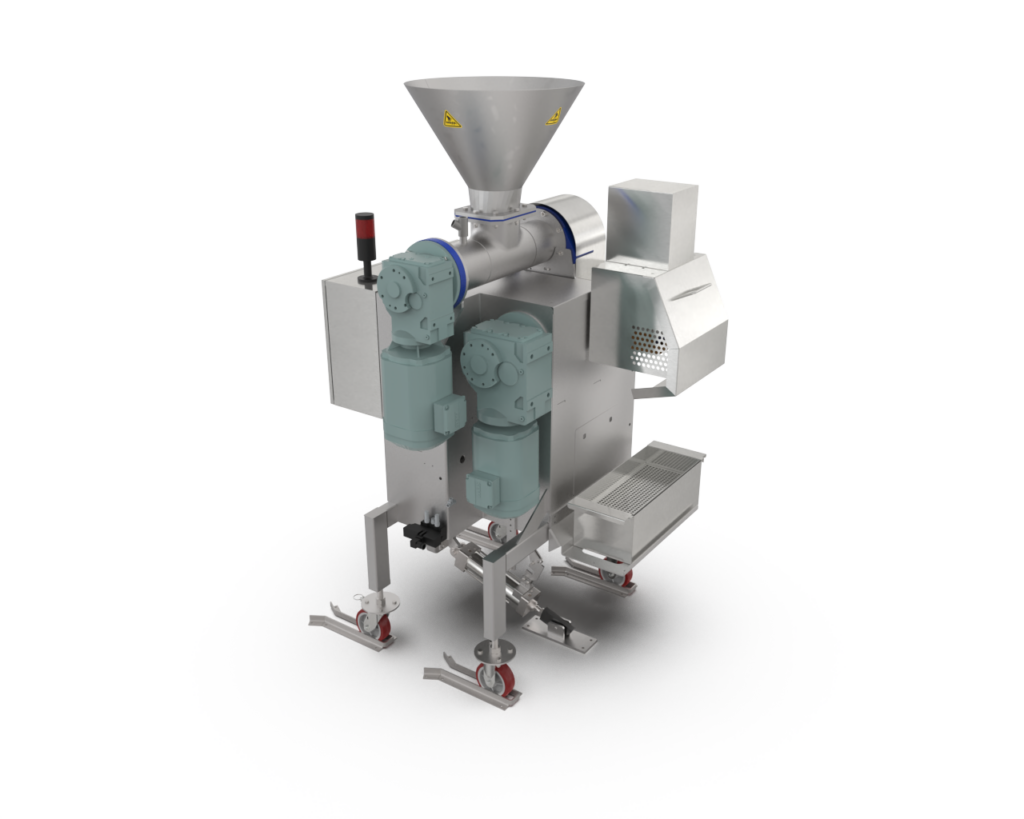

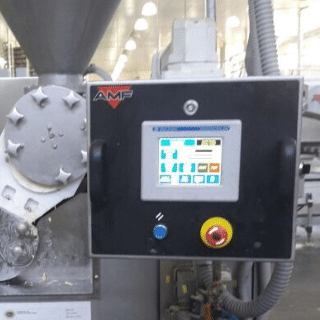

APEX DDM Mixer

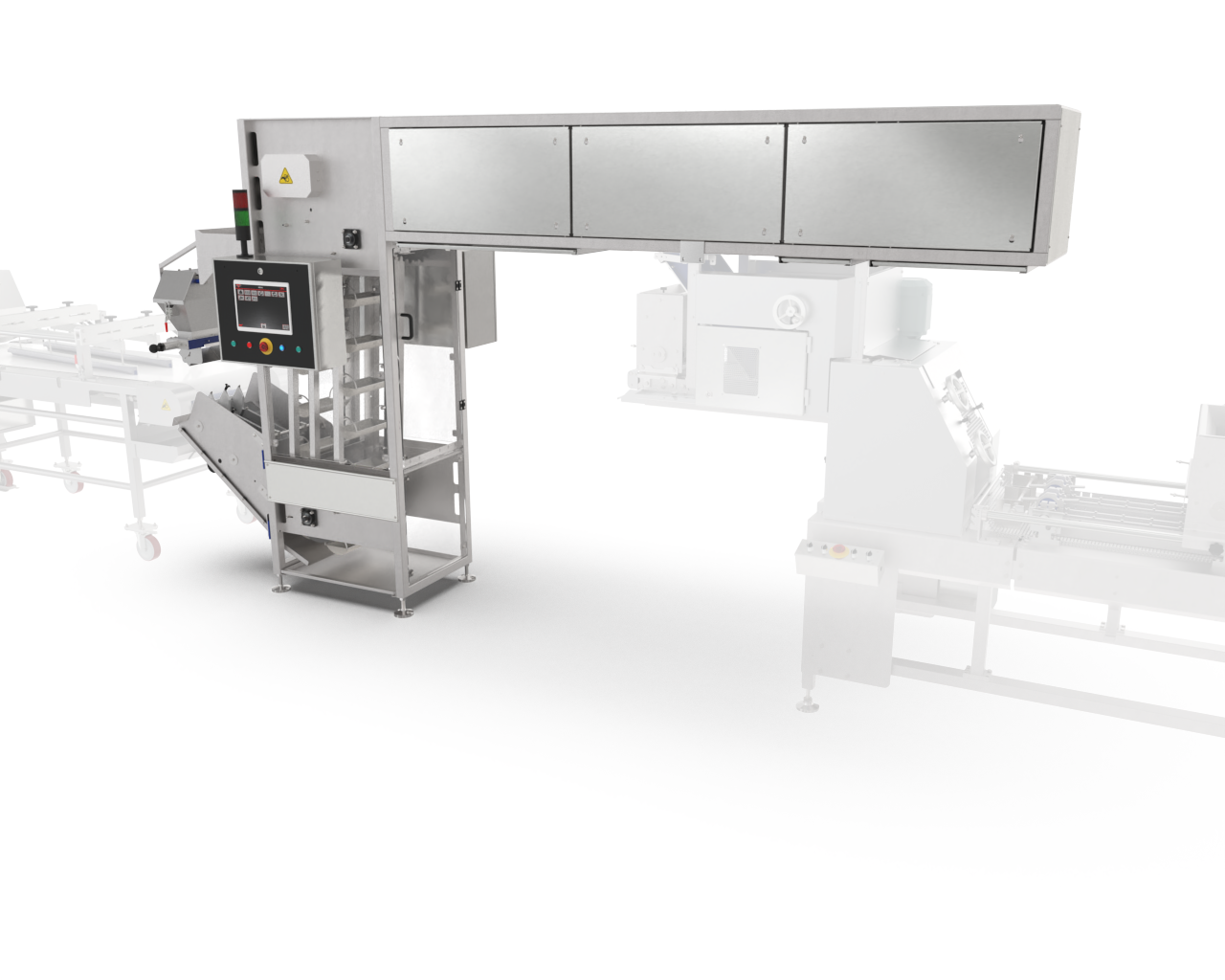

APEX Dough Chunker

APEX Double Incline Conveyor

News & Insights

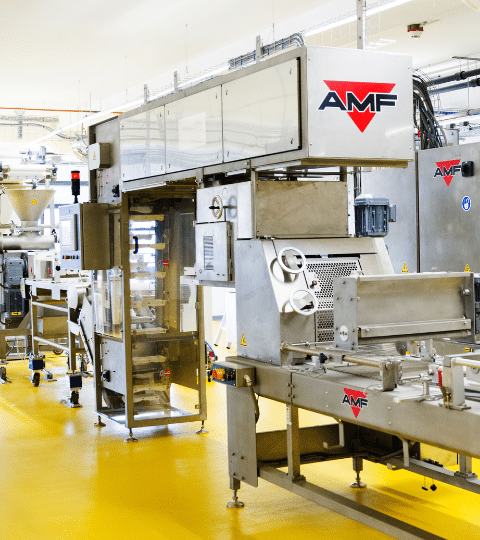

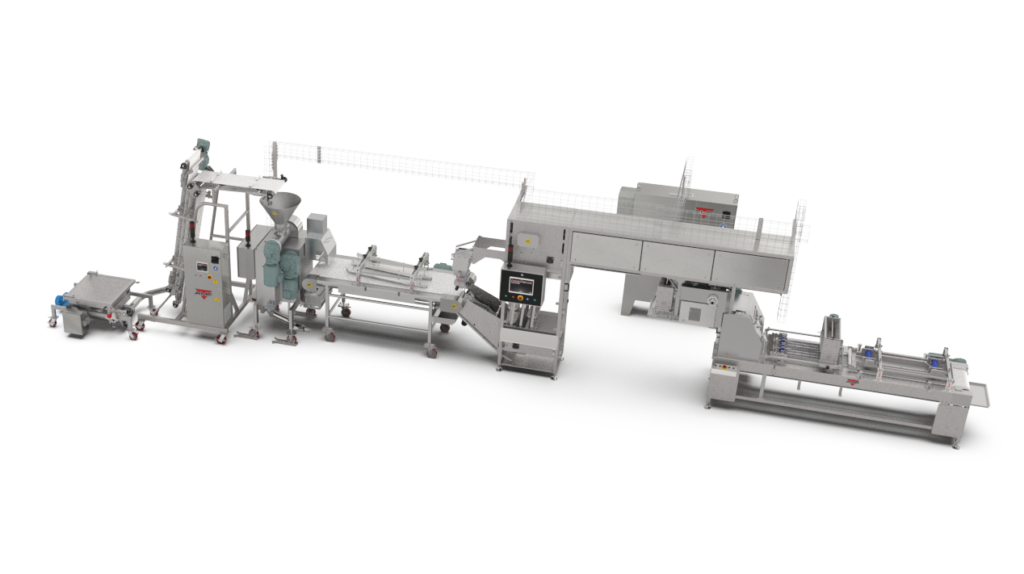

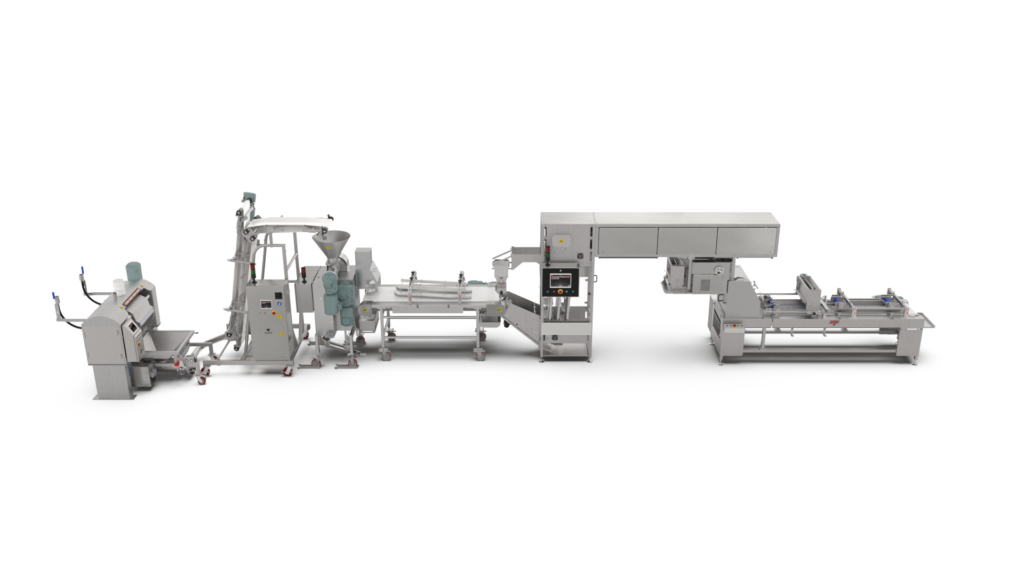

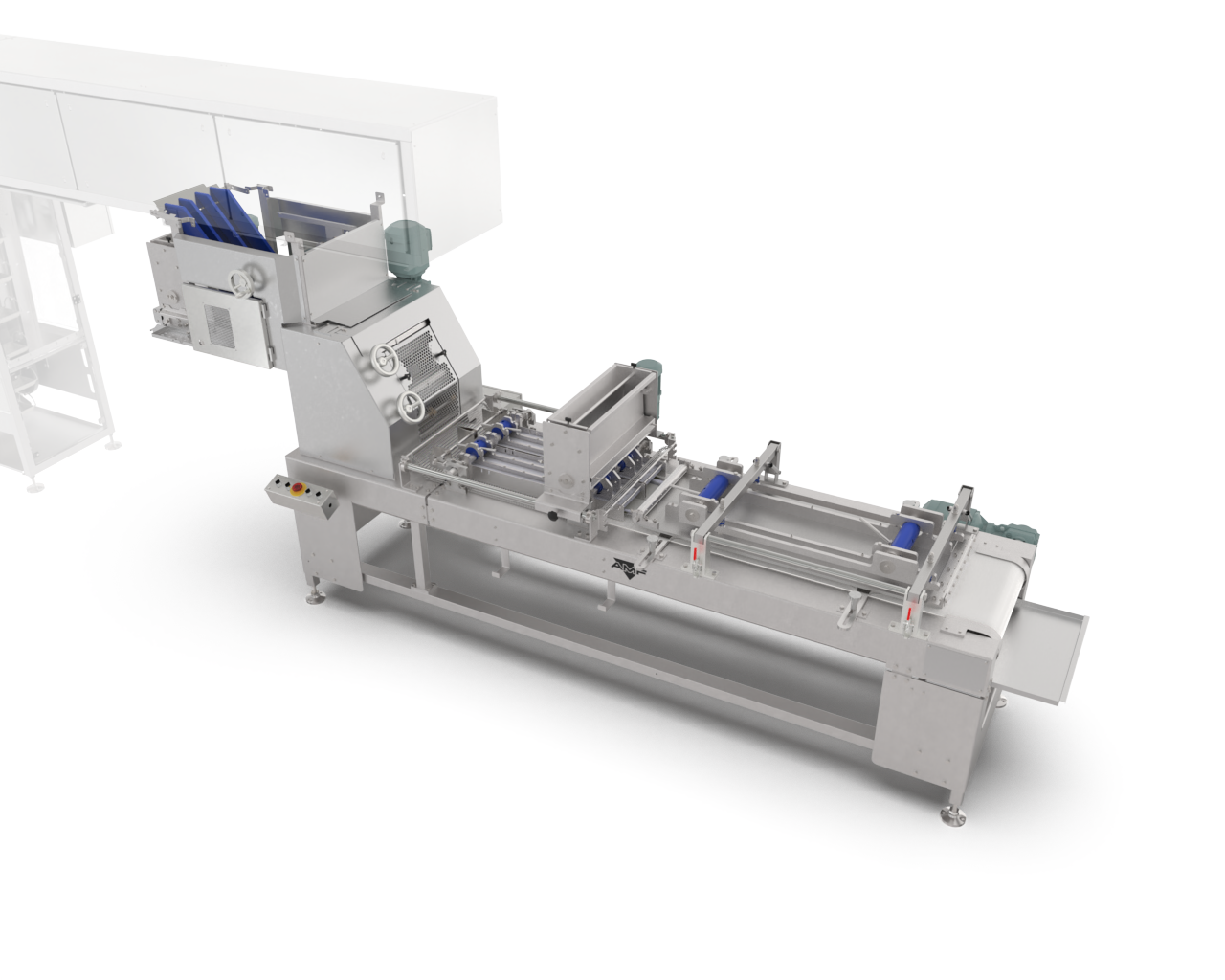

APEX Mini Combo BDR Bread & Bun Make-up System