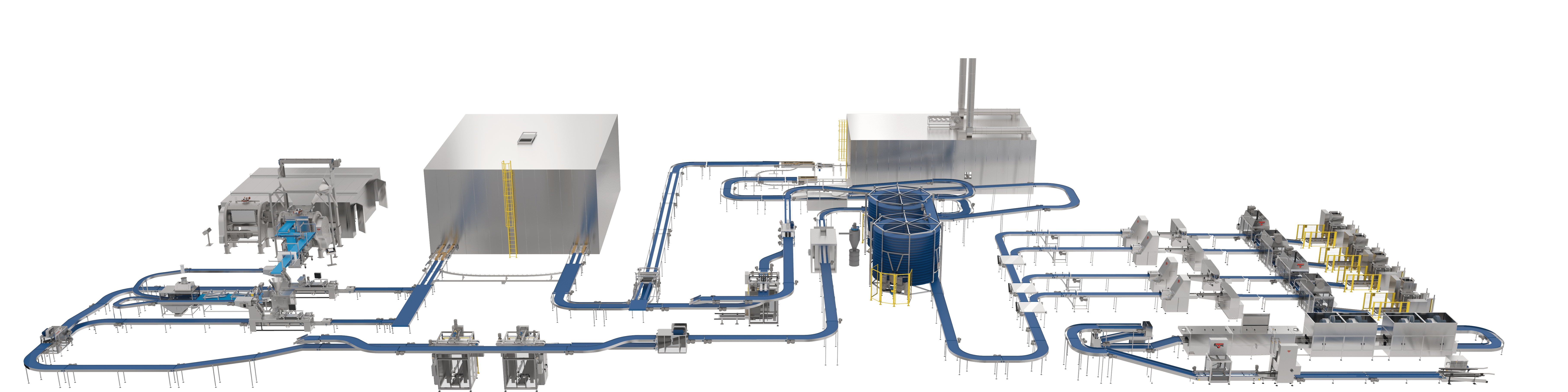

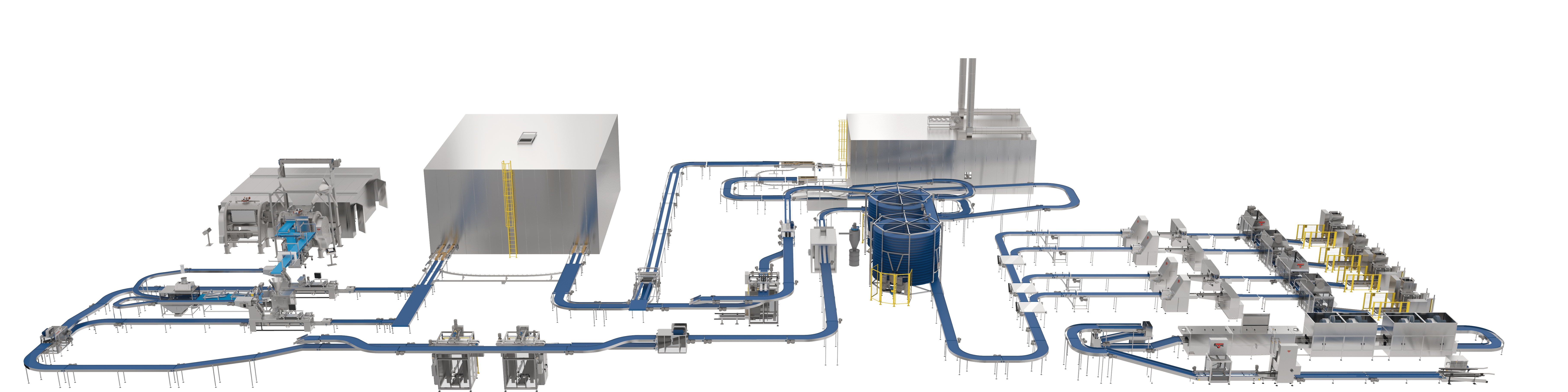

High-Speed

Soft Bread Systems

THE FULLY INTEGRATED SOLUTION for superior product, reduced risk, minimized complexity, lower operational costs, and cohesive control.

Producing from 600 to 13,500 loaves per hour, our best-in-class systems elevate your soft bread production. Explore the components of our High-Speed Soft Bread System and grow your bakery with AMF. Get in touch with your representative to discover the optimal solution for your bakery.

Click to expand

Click to expand

Click to expand

Click to expand

Advanced Monitoring

for Soft Bread Systems

AMFConnect™ ensures peak performance from your soft bread production line by providing real-time bakery system data and equipment information. Access critical operational insights and make informed decisions to enhance your soft bread system’s efficiency.

Fermentation Room

Custom-designed to meet specific fermentation times and production requirements for optimal dough development in a controlled environment.

Dough Trough

Transports dough through fermentation process and other processes throughout the bakery.

Trough Hoist

Raises and lowers the dough trough when feeding dough through final mixers or dividers.

Open Frame Mixer

Sanitary Open Frame Mixer with easy access, tubular offset frame for mixing doughs up to 3,200 lbs.

Dough Chunker & Elevator

Designed with simplicity in mind, the extremely gentle rotary blade can be combined with belt transfer systems up to 30,000 lbs./hour.

Raw Dough Conveyor

Customized by application to transport dough from chunker or pump to downstream operations.

ADD-S Divider

Precision dividing for the highest speed, bread production with quick-clean manifolds and easy-access frame design.

Flour Application & Recycling

Uniform flouring of a rounded bread dough balls to prevent sticking while maintaining a clean operating environment.

Straightline SMP (Sheeter/Moulder/Panner)

Easy-to-operate automated sheeting, moulding, and panning of pan baked bread up to 110 loaves per minute.

A-Series Conveyor

Designed for high operating efficiency and low maintenance, the A-Series Conveyors are built with anodized aluminum beaded plates and rust-free materials.

BakeTech Continuous Proofer

Industry’s leading proofer with the most available configurations and radiuses to fit virtually any layout.

BakeTech Continuous Oven

Flexible, multi-tier layouts maximize floor space with individually programmed temperature control zones and the most durable chain available.

Magnetic Pan Stacker/Unstacker

Versatile stacking or unstacking of pans or lids up to 40 per minute with easy automation integration.

Den Boer Depanner

Small footprint design gently removes product without damage.

Vesta Spiral Cooler

Custom-configured with the most sanitary, modular design elements for a variety of product applications.

Saber Bread Slicer & Mark Bread Bagger

Flexible for a variety of breads with automatic dual wicket changer and bag over bread scoop system.

VersaLoader Robotic Product Loader

Patented servo-controlled Gantry robotic arm for gentle product handling and tightly grouped product packages.

Bottom-Up Basket Stacker

Accurate, consistent and automated stacking up to 28 baskets per minute for all types of baskets.

Single Tunnel Basket Washing & Drying System

Continuous basket or tray washing and drying systems for optimal resource conservation.

Bottom-Out Basket Unstacker

Automatically unstacks standard nested or cross-nested baskets.

Basket Denester

Automatically separates cross-nested baskets after discharge from Bottom-Out Basket Unstacker.

Dry Trash Removal System

Removes trash and debris prior to sanitation for improved efficiency.