High-Speed Production Systems

for Buns and Rolls

The complete bun and roll solution for superior product, reduced risk, minimized complexity, lower operational costs, and maximum control.

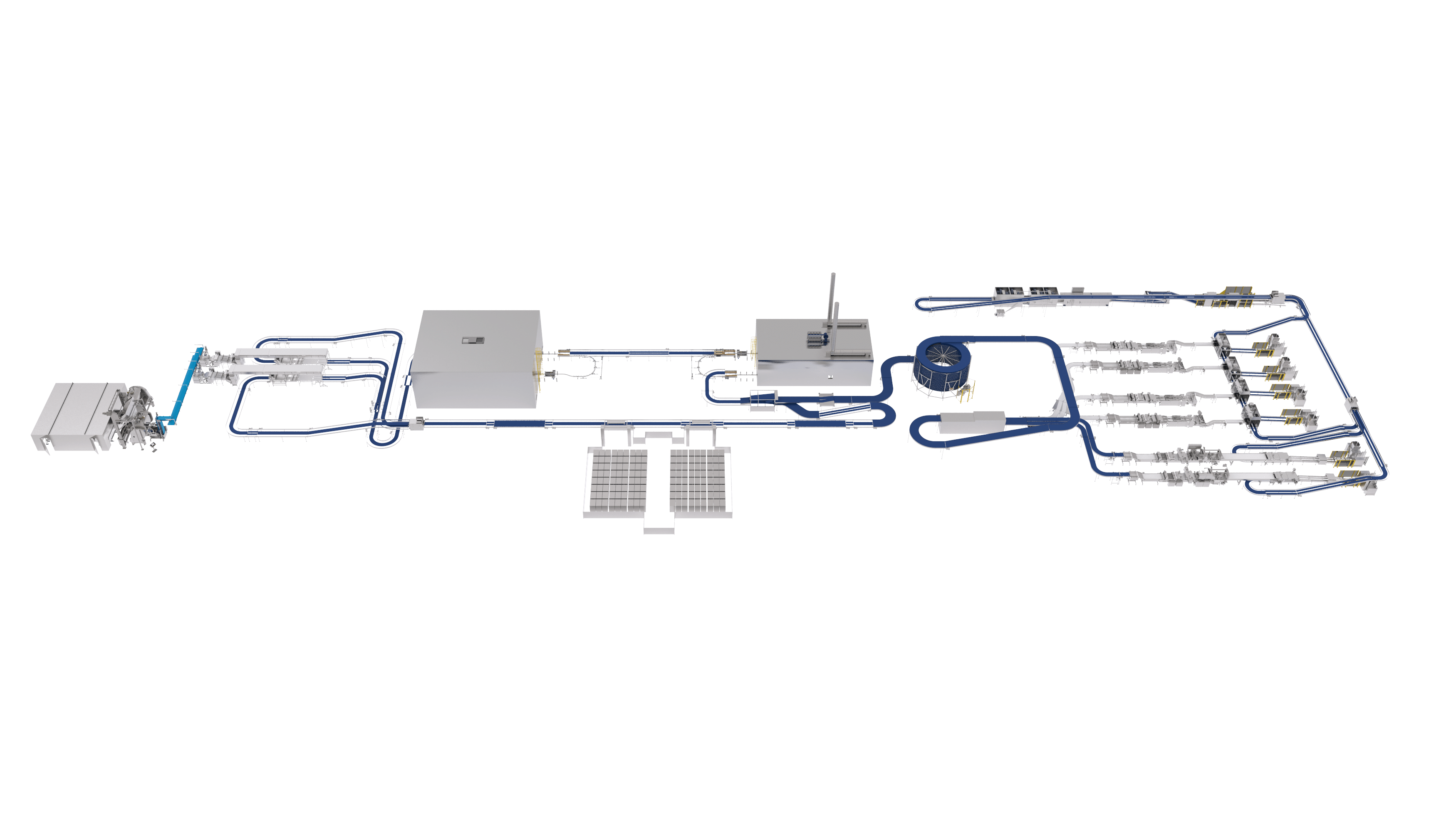

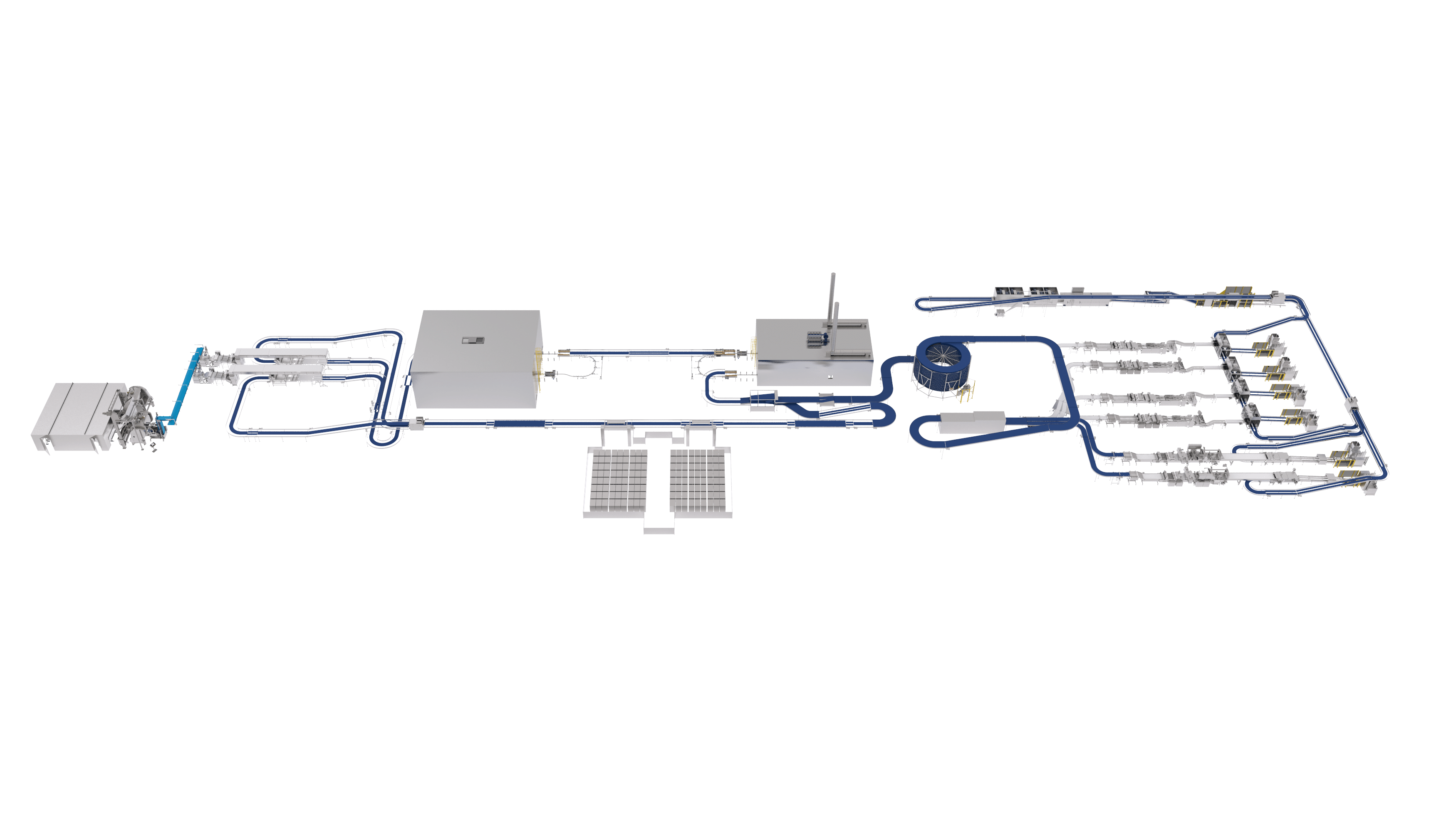

Experience the pinnacle of bun and roll production with AMF’s fully integrated high-speed systems. Designed for many types of buns and rolls, including soft hamburger buns, assorted rolls, and hot dog buns, our bun and roll production systems set the industry standard. With the precision of AMF’s FLEX extrusion dividers and top-tier sanitary designs, achieve unparalleled product quality and simple operation. Boost your production capacity to up to 96,000 buns or rolls per hour with our high-speed production lines.

Click to expand

Click to expand

Click to expand

Click to expand

SIMPLE MONITORING FOR

BETTER, FASTER DECISIONS

AMFConnect™ ensures the best performance from your bakery’s production line by providing access to the most advanced integrated, real-time bakery system data and unit equipment information. Access to critical operational information allows your team to make better, faster decisions improving operations and efficiency throughout your bakery.

Fully- Automated Fermentation Room

Custom-designed to meet specific fermentation times and production requirements for optimal dough development in a controlled environment.

Dough Trough

Transports dough through fermentation process and other processes throughout the bakery.

Dough Trough Hoist

Raises and lowers the dough trough when feeding dough through final mixers or dividers.

Open Frame Mixer

Sanitary Open Frame Mixer with easy access, tubular offset frame for mixing doughs up to 3,200 lbs.

Dough Chunker & Feeder

Designed with simplicity in mind, the extremely gentle rotary blade can be combined with belt transfer systems up to 30,000 lbs./hour.

Raw Dough Conveyor

Customized by application to transport dough from chunker or pump to downstream operations.

HBDFlex Accupan High Speed System

Highest speed bun system available up to 72,000 pieces per hour with FLEX technology for unmatched scaling accuracy.

A-Series Conveyors

Sanitary, premium conveyor design engineered with a bent plate structure to facilitate wash-down sanitation.

BakeTech Continuous Proofer

Industry’s leading proofer with the most available configurations and radiuses to fit virtually any layout.

BakeTech Continuous Oven

Flexible, multi-tier layouts maximize floor space with individually programmed temperature control zones and the most durable chain available.

Den Boer Depanner

Small footprint design with air jet assembly and vacuum system to gently remove product without damage.

Vesta Spiral Cooler

Custom-configured with the most sanitary, modular design elements for a variety of product applications.

Robotic Pan Stacker/Unstacker

Patented soft-touch end-of- arm tool gently stacks and unstacks multiple units at one time for longer pan or lid life.

HS40 Bulk Bun Packer

Flexible and easy changeover, designed with regrouping section, vacuum evacuation,and hot air side seal.

VersaLoader Robotic Product Loader

Patented servo-controlled Gantry robotic arm for gentle product handling and tightly grouped product packages.

Bottom-Up Basket Stacker

Pre-programmed and responsive to system demand, consistent and specific handling up to 28 baskets per minute

Bottom-Out Basket Unstacker

Handles up to 40 nested or cross-nested baskets per minute with adjustable widths for easy changeover.

Dry Trash Removal System

Configurable for “S” style, horizontal, or vacuum for more efficient and complete pre-sanitation waste removal.

Single Tunnel Basket Washing & Drying System

Flexible layout continuous washing and drying for improved resource conservation.