Pizza bakery Intelligence

AMF recognizes the challenges of modern bakeries. Traditional focus on consistent product quality, efficient production processes, and bottom-line costs remains. At the same time new topics become more important each day: sustainability, food waste, and a changing workforce.

At AMF, we strongly believe that we can support modern bakeries by merging the virtual and physical world to continuously drive optimization. By working towards a lights-out bakery with our expert baking experience, we are making equipment smarter, integrating processes, and improving your operation.

Sustainability

One of the core pillars of AMF’s Smart Process Solutions is sustainability. We’re determined to help pizza bakeries improve energy consumption and reduce CO2 emissions. By optimizing processes and leveraging intelligent technology, we’re making significant strides in minimizing the environmental impact of the pizza production industry.

Food waste

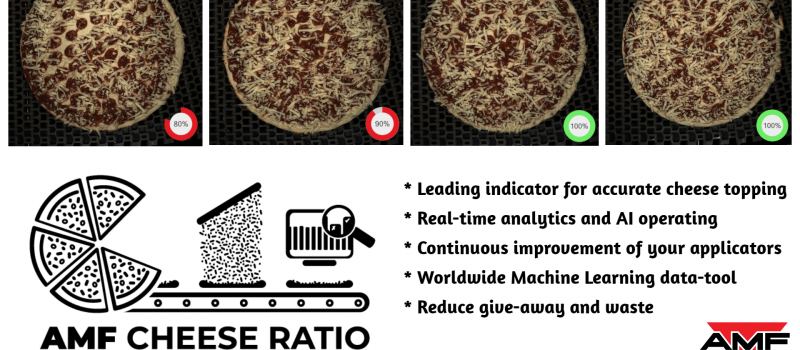

Food waste is an ever-present and concern in the food industry that continues to gain visibility. With our Smart Process Solutions, we’re committed to reducing waste and give-away while increasing yield. Through data-driven insights and precise control, we empower pizza bakeries to make the most of their ingredients, ensuring nothing goes to waste.

Quality

Maintaining consistent product quality while scaling production is paramount. Our solutions simplify operations while enhancing quality consistency. With intelligent equipment and integrated processes, we’re helping pizza bakeries produce top-notch pizzas with ease.

A fully data-driven process

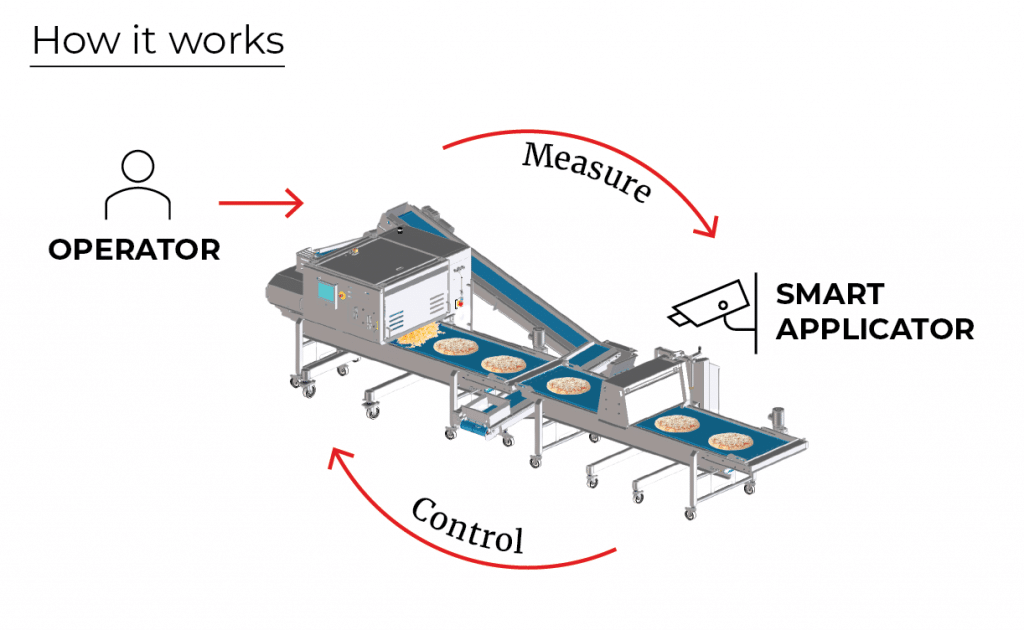

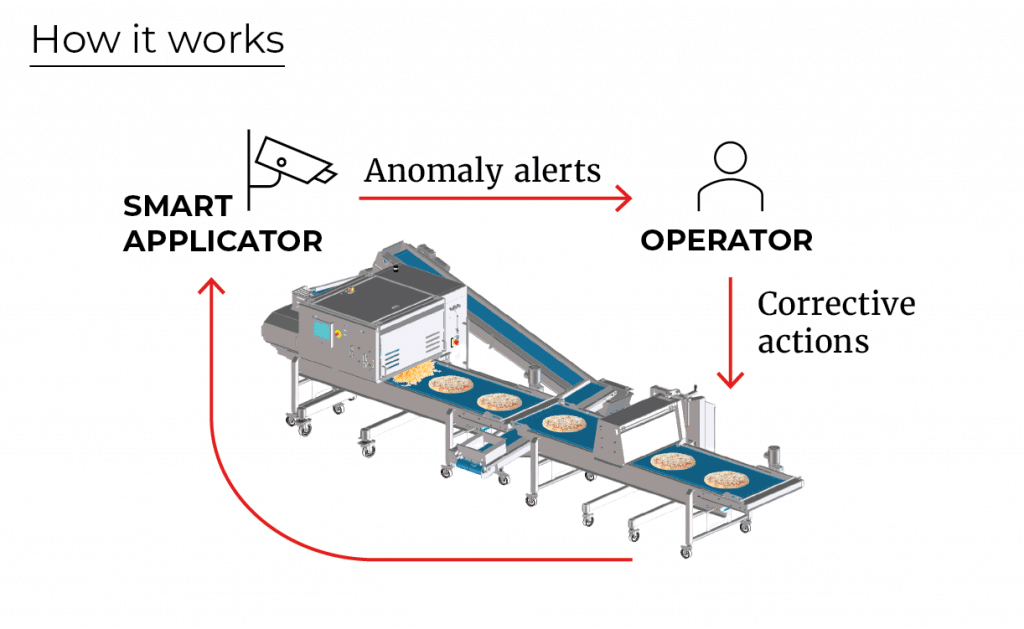

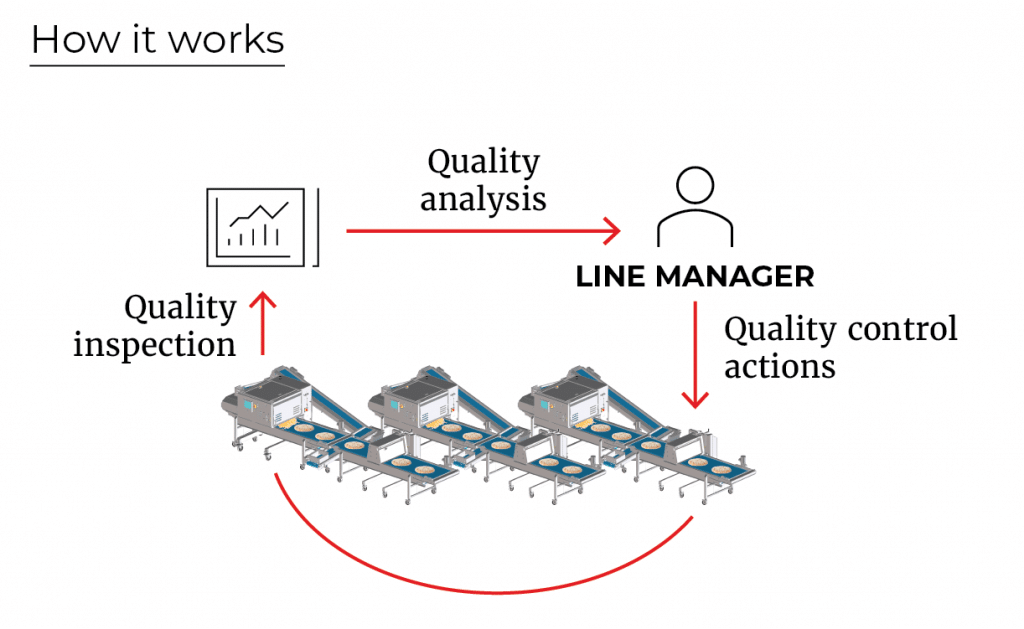

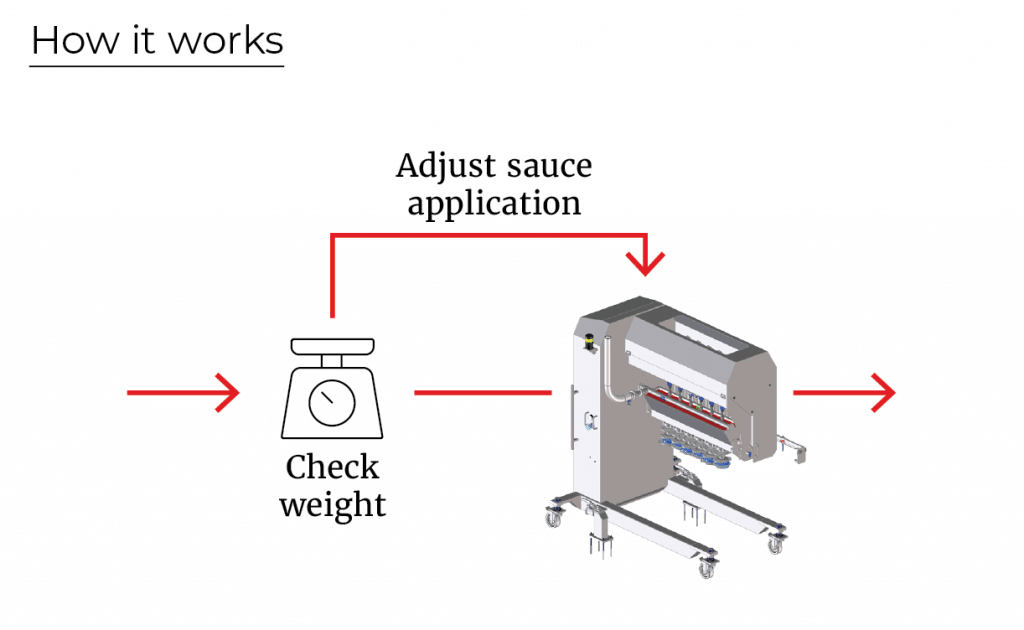

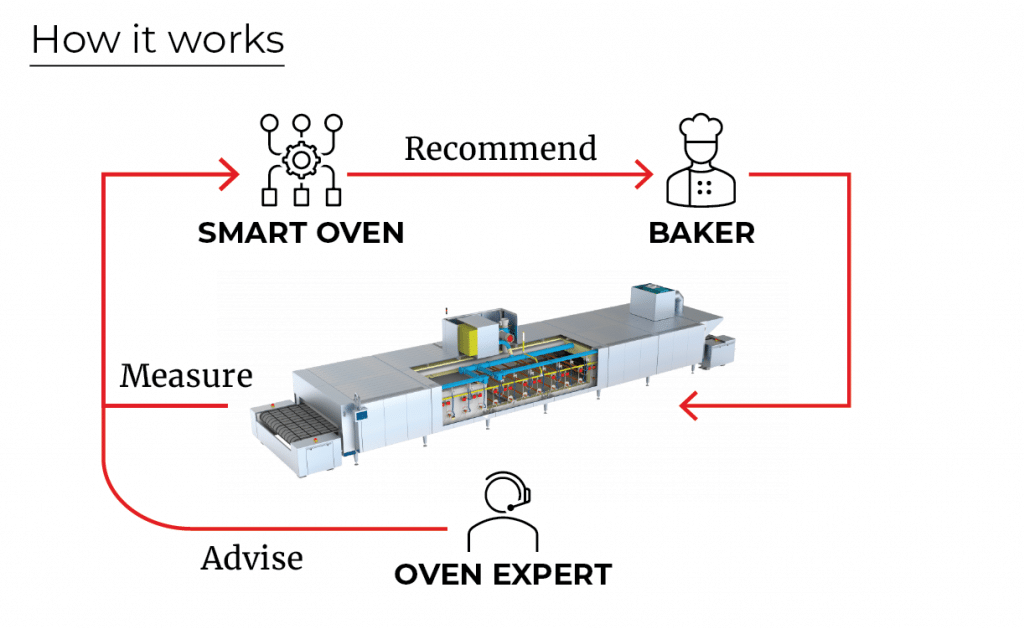

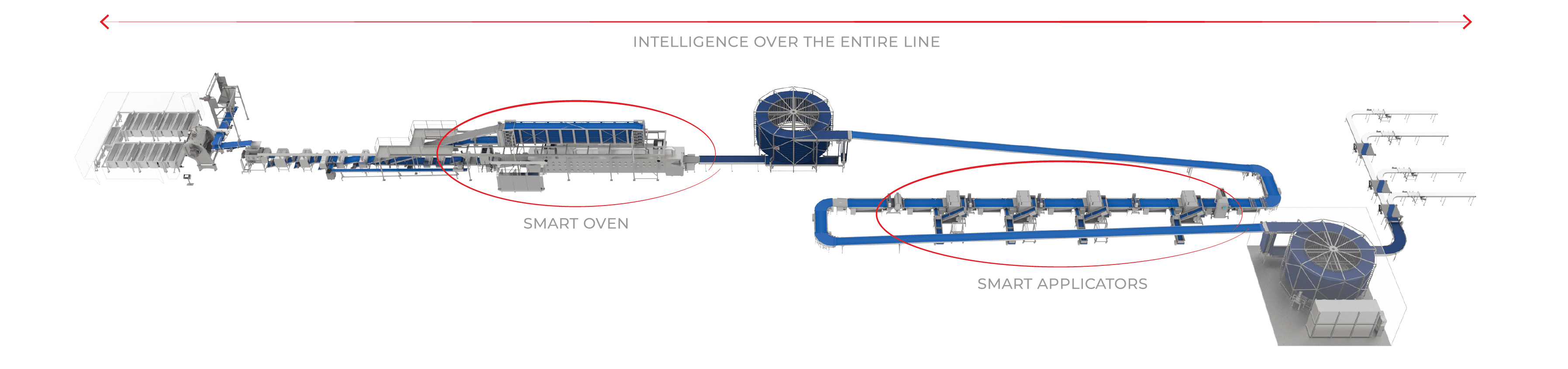

In our pizza production line systems, intelligence operates on two levels. Vertically, smart machines like ovens and applicators offer closed-loop unit control. Horizontally, we connect the entire baking process, implementing closed-loop control for the entire bakery, from tracking and tracing to maintaining line quality and predictive maintenance.

Interested? Feel free to book a demo

or request potential savings

Adding Intelligence to pizza production

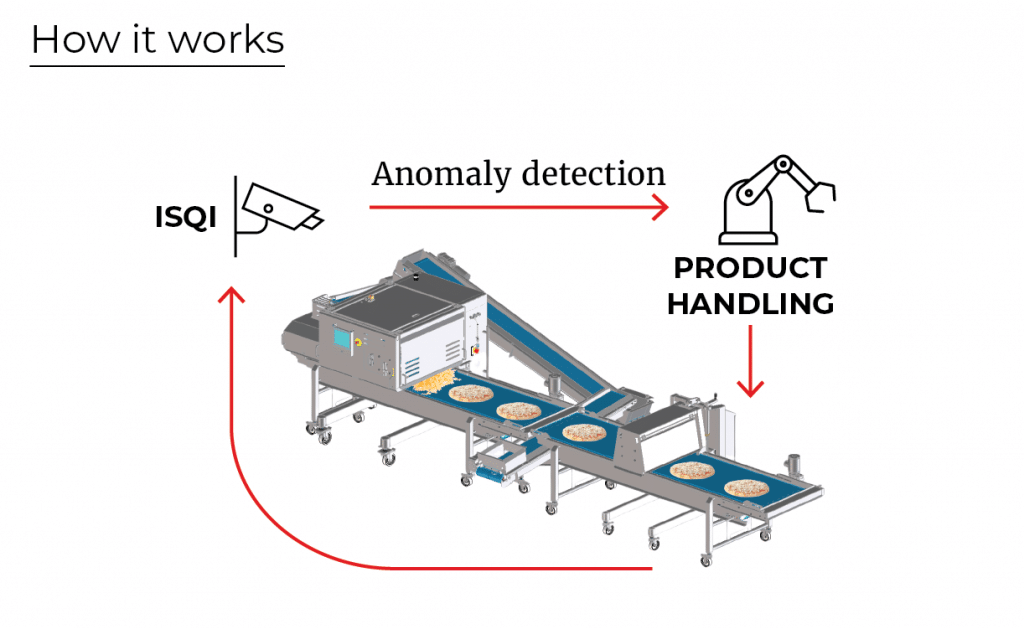

New technology makes it possible to take our advanced equipment to the next level. We are in a unique position to add intelligence to our equipment and integrated production lines. With the use of advancements in artificial intelligence, connectivity, and data processing, we are making pizza production more autonomous.

An important part of our approach for enhancing pizza production is to keep the operator in the loop to make sure quality and efficiency are improved and not impacted.

Download Brochure

Expert knowledge

AMF’s expert knowledge ensures that we address bakery challenges effectively. We leverage artificial intelligence to simplify operators’ tasks and improve overall operations.

Artificial Intelligence

Making the life of an operator easier and improving operations

Connectivity

Effectively aggregating information is crucial for the implementation of quick and correct decisions. Our solutions facilitate seamless connectivity, ensuring data-driven insights are readily available to support bakery operations.

- SMART APPLICATOR

- IN-SHIFT QUALITY INSPECTION

- ACROSS-SHIFT QUALITY INSPECTION

- QUANTITATIVE INGREDIENT COMPENSATION

- ACTIVE QUALITY REJECTION

- Sustainable Oven Service

Product image gallery

CONTACT US TO LEARN MORE

Book a demonstration of our Smart Process Solutions at the AMF Innovation Center (virtual or in-person). RSVP with your preferred date and we will contact you with more details.

Request a free calculation of your potential savings and ROI with AMF’s Smart Process Solution, delivered within 2 working days.

Learn more about AMF’s solid and liquid topping applicators engineered by AMF Tromp for the most precise topping applications and product consistency.