Baking Technologies For Pizza

According to Business Wire research, the global pizza market reached US$233 billion in 2023. With numbers like that, it’s easy to ask, “What’s the secret to a great pizza?” Things like a great crust, delicious toppings, and the confidence that it will taste the same every time are what’s at the forefront of consumers’ minds. While those requirements seem obvious for consumers, for bakers, a lot more goes into producing that final perfect pizza product.

For pizza and flatbread producers, delivering a premium product relies on the process and technology involved. From mixer to marketplace, AMF Bakery Systems’ best-in-class unit equipment and complete system solutions help bakers achieve premium product quality for thin-and-crispy, deep dish, handheld snacks, thick or stuffed crust pizza products. Our latest SlideShare on complete pizza systems provides an overview of the proofer, ovens, and coolers that bakers worldwide rely on to get their slice of that $233 billion dollar pizza market.

The Proof is in the Process

When developing a new pizza and flatbread process or optimizing an existing line, versatility in your technology options is critical. Pizza makers can maintain product integrity and maximize production with best-in-class equipment solutions. An essential step in the pizza and flatbread production process includes proofing the dough. Proofing is necessary for pizza and flatbread production because it allows the yeast to rise and create air pockets resulting in a better quality pizza.

In the pizza industry, the AMF Tromp Multideck Belt Proofer is used to proof individual products before baking. This method can be used for products with or without decoration, and it doesn’t require the use of trays, which reduces energy consumption and capital investment costs. Proofing times can be easily adjusted with flexibility for varying proof times and the closed belt minimizes the chance of misshaping the product. Additionally, the belt proofer allows for a direct transfer onto the oven belt, freezer belt, or pizza topping line. This proofer type is ideal for pizza dough or bases that have already been cut into the desired shape and size.

The AMF Vesta Spiral Proofer is built with an easy-to-assemble enclosure that improves air flow circulation and controls temperature, humidity, and proof time parameters. These specifications optimize the fermentation process and create a desirable environment for maintaining pizza and flatbread flavors and texture while traveling through the resting period. In addition, modern proofing allows bakers to program recipe memory, access advanced diagnostics, utilize automated controls, and track product data to improve their operations.

Bake it Right

No slice of pizza or flatbread would be enjoyable without being baked to perfection. With the right baking technology, bakers can consistently produce pizza and flatbread that is delicious and high quality.Modular, AMF Den Boer Tunnel Ovens have independently controlled temperature zones and controlled air flows, providing bakers maximum control over their baking environment for premium product quality. The modular design ensures efficient delivery and installation while allowing room for future portfolio growth.

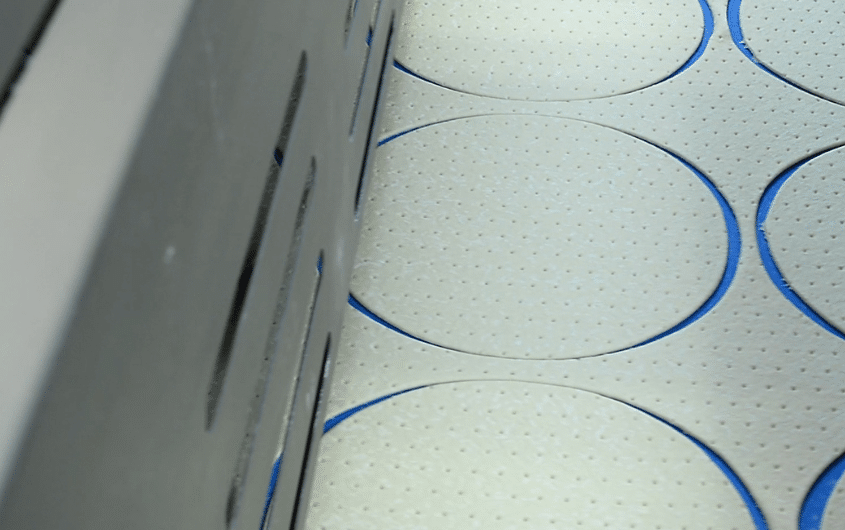

The Multibake® HT Tunnel Oven

For seamless operation, even under challenging and confined conditions, the Multibake® HT Tunnel Oven by AMF Den Boer, offers a high-temperature production environment with no risk of flashback thanks to the burner surface being heated up to 1050°C. The large opening angle of the burner ensures that infrared radiation is uniformly dispersed throughout the area. This oven is frequently used in the production of pre-baked items for supermarkets and food service, such as pizza, frozen pizza, flatbread, naan, pita, and other similar products. The Multibake® HT Tunnel Oven is an excellent solution for various applications in the food industry that require extremely high temperatures during baking. This high-temperature oven allows for high-speed baking at high temperatures on a production belt.

The Correct Temperature

AMF’s Vesta Spiral Cooler allows ambient air to circulate baked pizza products and gradually decreases the internal temperature to maintain optimal flavor and texture in a continuous delivery. Ambient humidity and temperature data acquisition with adjustable traveling time parameters create a desirable cooling effect throughout the traveling period. Available in a single or dual configuration, it’s compatible with AMF’s proprietary AMFConnect™ data tracking and management solutions, allowing real-time process adjustments to ensure a consistently great-tasting product.

At Your Service

As energy prices rise, pizza producers feel the squeeze on their profit margins. Thankfully, they now have the option of using artificial intelligence (AI) to make their process more efficient and to mitigate the effects of inflation. Advances in sensor technology have made it possible for AMF to engineer smart, connected ovens that use data-based insights to reduce production costs. Through an array of advanced sensor technology, the AMF Bakery Systems’ Sustainable Oven Service (SOS) continuously monitors how ovens are used and how they are performing.

When connected to the Bakery Intelligence cloud, bakers can see real-time recommendations by AMF’s oven experts tailored to their bakery’s exact setup and process. It informs operators how to adjust equipment for optimal baking conditions across the following four KPIs:

Occupancy – average product throughput

Availability – actual time that the oven was ready for baking

Baking condition – to what extent the desired baking conditions are achieved in the oven

Eco-efficiency – the normalized amount of gas used per baked unit

The benefits of investing in the right pizza and flatbread system solutions for your bakery cannot be understated. Whether scaling output or seeking more efficient processes, commercial bakeries can lower expenses and increase margins by implementing new and innovative production technologies.

Contact the AMF team today to discuss your current pizza project.