Dough Sheeting & Laminating

Many products in bread and pastry are created from sheeted and laminated doughs. Using low-stress systems, dough properties stay intact and final products adhere to consistent quality standards. Moulded, cut, and rounded bread, danish pastry, croissants, and pastry snacks are all made on these sheeted dough lines. With the leading hygienic design, process-driven and flexible systems by Tromp set the market standard for entry-level and high-speed lines.

Dough Sheeters

Sheeted doughs are the basis of make-up for many products. Stress-free sheeting from dough chunks or extrusion with 3-rollers creates a sheet depending on the required dough.

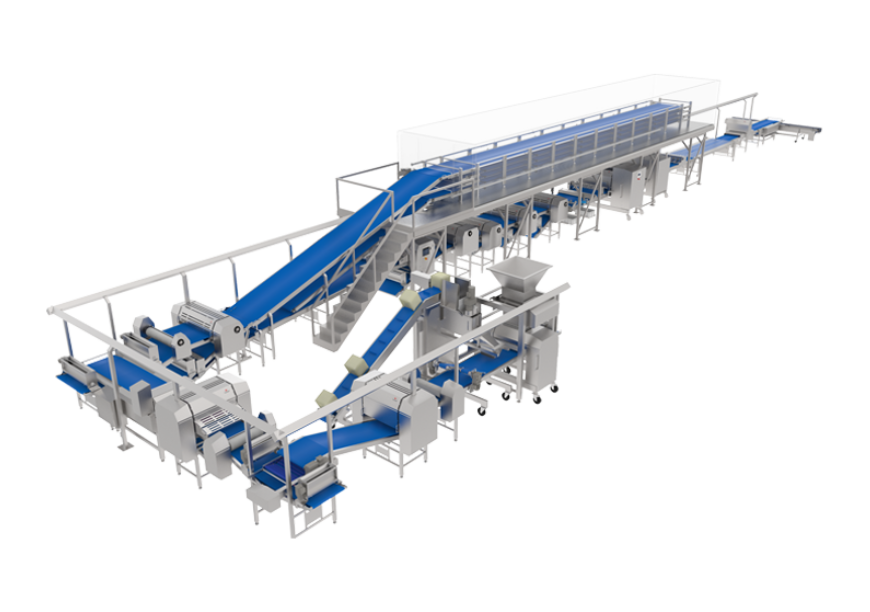

Stress-Free Sheeting Line

High-speed, stress-free dough make-up for products like pizzas, flatbreads, pita, naan, swirl breads, and more. This is the ideal sheeted industrial pizza line for both American and Italian style pizza, and even for high hydration dough types, such as sourdough or gluten-free.

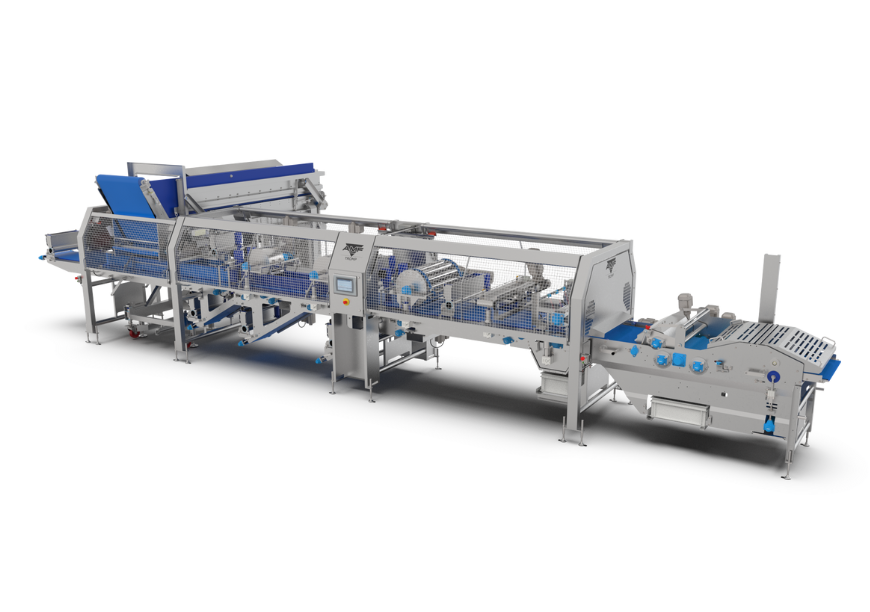

Stress-Free Artisan Sheeting Line

High-speed, stress-free artisan bread production of consistently moulded, cut, and rounded bread products for premium baguettes, petite pans, ciabatta, tin bread, dinner rolls and more.

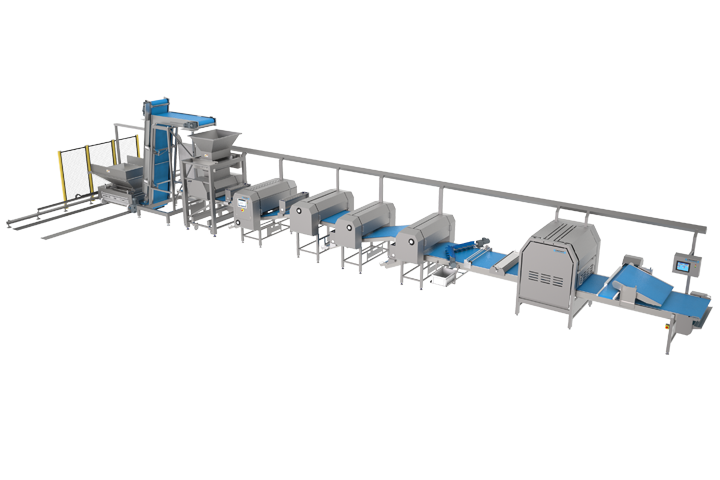

Extruded Sheeting Line

Maximum product flexibility with unmatched accuracy across a wide range of pizzas, flatbreads, naan, and more. The Extruded Sheeting Line is suitable for green doughs and even more stiff doughs. Extruded dough sheets are part of the laminating process for pastry dough lines.

Dough Laminators

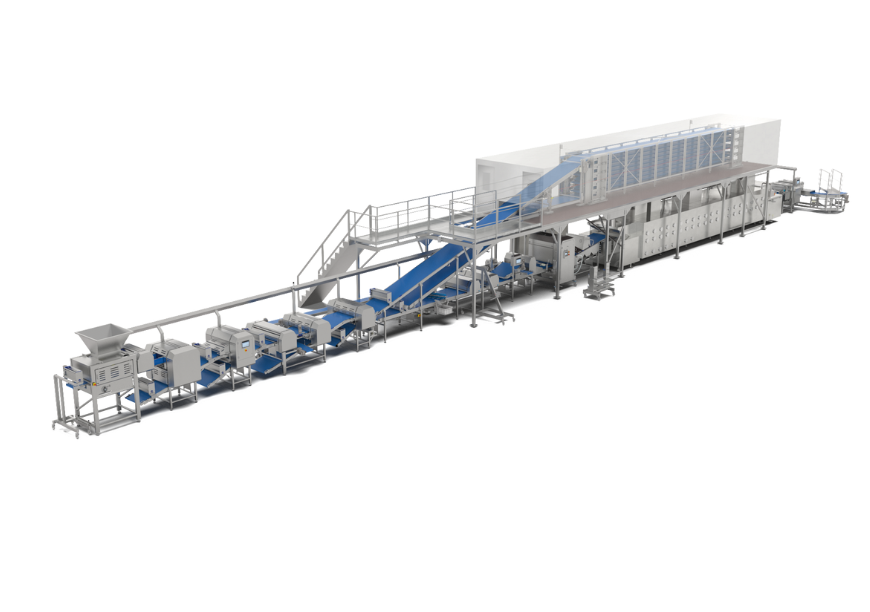

Laminating Line

Offering high-speed, stress-free, or extrusion laminating for the production of croissants, pastries, danish, and puff pastry products, our laminating line creates up to 1,000 layers of dough and fat for the richest and most crispy pastry products and croissants. Our laminators for entry-level to high-capacity production come in L-shape and U-shape layouts, depending on the space in your facility.

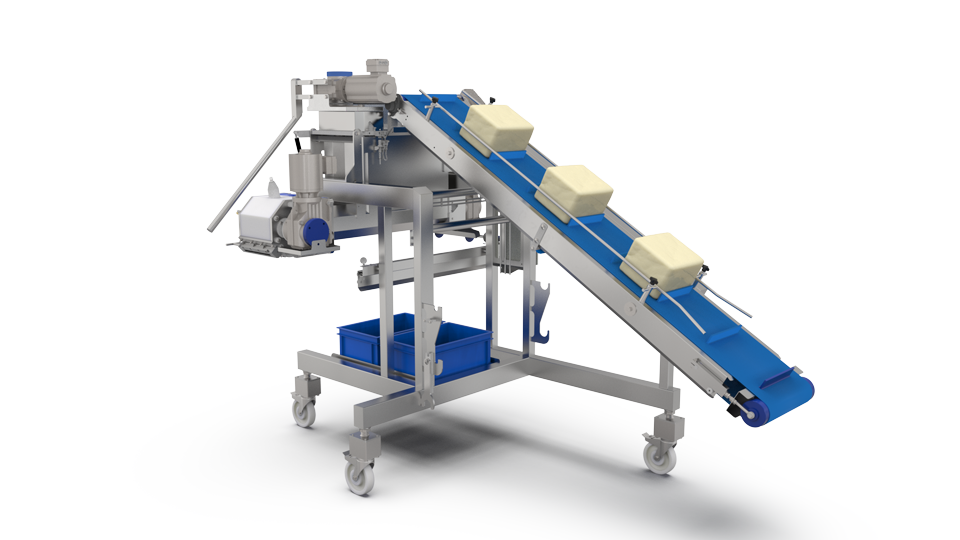

Fat & Butter Pump

Easy to operate and integrate into existing lines, this reliable fat pump is used to laminate dough and fold the fat into it, handling margarine, butter, vegan fats, and transfats. The pump feeds the fat directly above the dough sheet without piping or waste. It is a component of the Tromp laminating dough lines for pastry and croissants or products like Pão francês.

Universal Make-up Lines

Uni-Line T600

Universal make-up line for depositing various fillings like sausage rolls, apple turnovers, D-shape, Chelsea bun, Pain au Chocolate, and much more. Entry-level automation for bakeries and very flexible for product changeovers throughout shifts. Sheeted dough from a roll/sheeting table can be fed to start the make-up process. With high productivity for low/medium production capacity, it can be operated by a single baker.

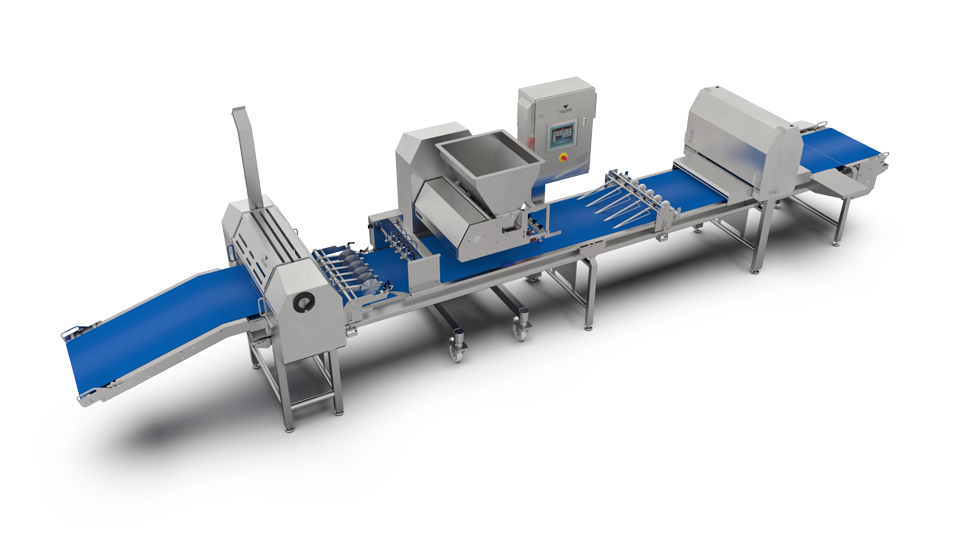

Tromp Reduction Station

A standalone unit or integrated with a make-up line to reduce blocks of dough. The dough is reduced using a multi-roller, cross-roller, and gauging station to an end thickness of 4 mm (based on an in-feed thickness of 50 mm).

AMF’s Sheeting & Laminating BRAND

Tromp

Designed with an end-product focus, Tromp’s sheeting and laminating solutions are leading technologies in the make-up of dough and snack products. They are engineered to meet the highest hygiene standards with an open frame design for quick and easy cleaning using no tools and food-safe products. Process control and flexibility with minimal operator intervention allow bakeries to operate at high capacity and produce a large diversity of products per day or shift.

Find Your Sheeting & Laminating Solution

Use our Bakery Solutions Finder to search for AMF equipment by Products, Processes, & Brands.