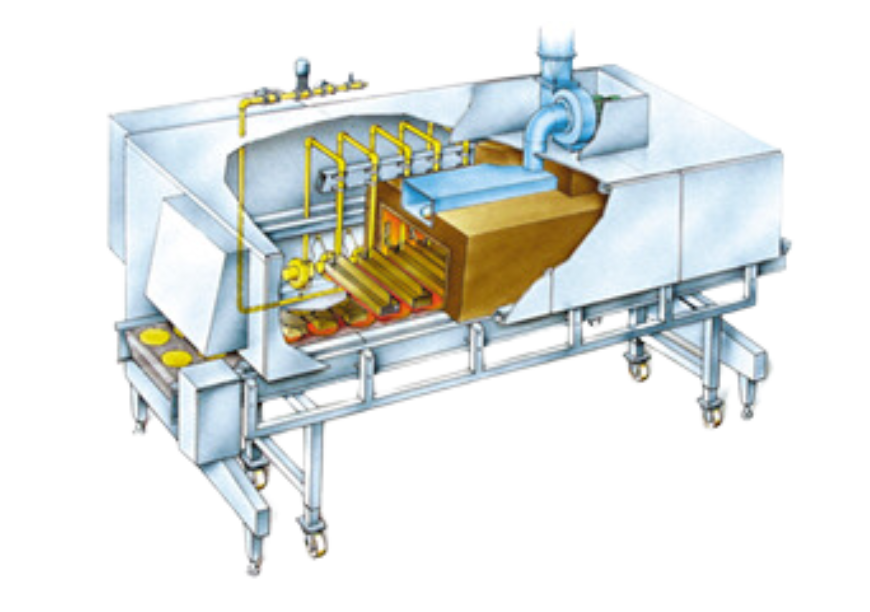

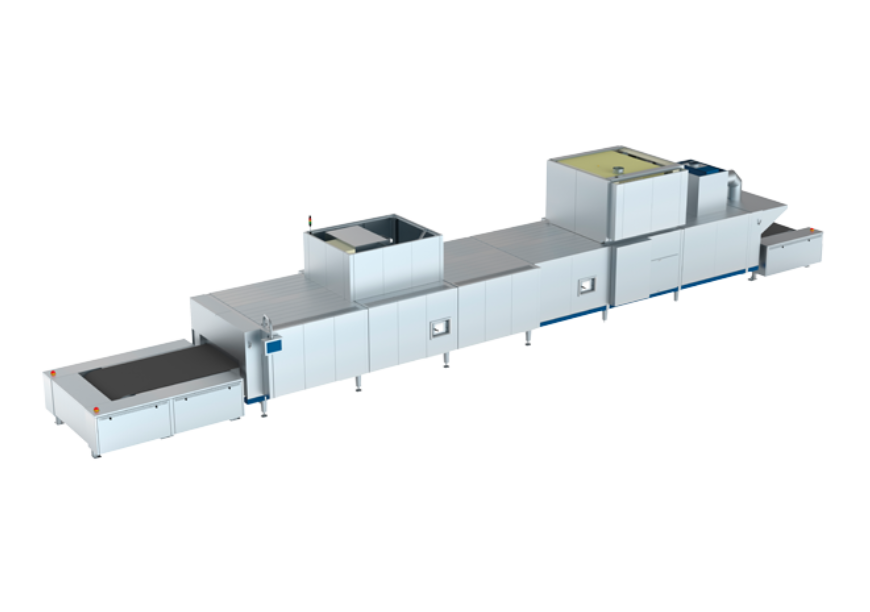

Multibake®-IR Tunnel Oven

Additional Media

Visit Our innovation centers

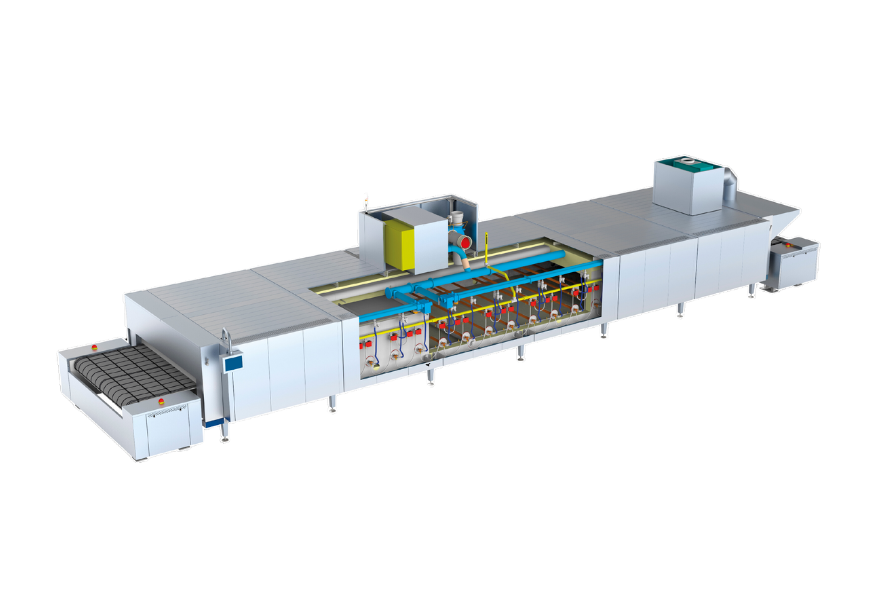

More Tunnel Ovens by AMF Den BOer

Multibake®-D Tunnel Oven

Multibake® VITA Tunnel OVen

Multibake®-H Tunnel OVen

News & Insights from AMF Den Boer

Download the Den Boer Tunnel Oven BROCHURE