Baking sustainably to beat fuel price rises

We’ve all seen gas and energy prices rising sharply over the past few years, and for energy-intensive industries, this can be an especially big issue! Unfortunately, bakery ovens can be big consumers of natural gas, and when combined with the rising cost of ingredients, this means bakeries are being hit especially hard. With recent geopolitical events set to send the price of gas rocketing even further, now is a good time to start thinking of ways to make your bakery more resilient to price rises.

So, what can our industry do to combat these aggressive increases? Thankfully, gas is no longer the only option when it comes to powering bakery ovens. Smart bakery owners all over the world are already investing in gas alternatives to power their ovens. As well as protecting your bottom-line, this has the additional advantage of making your bakery more environmentally friendly, since the less gas you use, the less CO2 your bakery will emit.

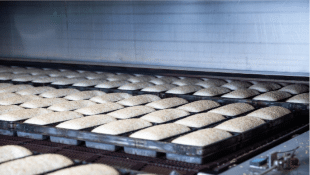

AMF Den Boer has over 100 years of experience in building tunnel ovens, and we have created many solutions that use less gas – better for your results and better for the planet! It’s no surprise, then, that we are currently seeing a high demand for our electric and hybrid tunnel ovens. More and more customers are discovering the performance and cost benefits of these gas alternatives, which perform especially well for baking soft bread, artisan bread, pizza, flatbread, pastry and croissants, rusk, and cake products.

For an even more sustainable solution, AMF Den Boer has even introduced the world’s first Hydrogen-fuelled oven, the Multibake VITA, providing the possibility for true net-zero baking, without any CO2 emissions! The oven’s only by-products are steam and water, which can even be recycled into the baking process for even better product results.

With many modular, turn-key solutions available to suit your bakery’s size and production requirements, AMF Den Boer is sure to have a gas-alternative solution to fit your requirements and budget. And it’s not even necessary to invest in completely new equipment: our skilled engineers are experts at retrofitting AMF Den Boer tunnel ovens to make them electric or hybrid. What about the time cost of retrofitting? Our installations are so efficient that you can get your oven back up and running – and start seeing the cost savings – in a matter of days.

Electrical ovens can also target heat much more accurately than gas-powered ovens, guaranteeing an even heat transfer to the product. This is because there are several elements in each module, with some of the elements directly above the products to be baked, and some underneath. Electrical tunnel ovens also have fewer moving parts than other continuous ovens, making them easier to clean and maintain.

So, for savings of up to 30% versus natural gas, a lower environmental impact, and increased energy independence, electric ovens are fast becoming a future-proof solution for more and more bakeries. Supported by local service, maintenance, parts, and remote oven services will ensure you flawless results and a happier balance sheet.

For more information on AMF Den Boer’s electric and hybrid ovens, please contact sales@amfbakery.com or visit our website for more information: https://amfbakery.com/den-boer-tunnel-ovens/