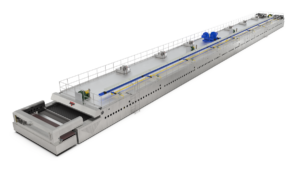

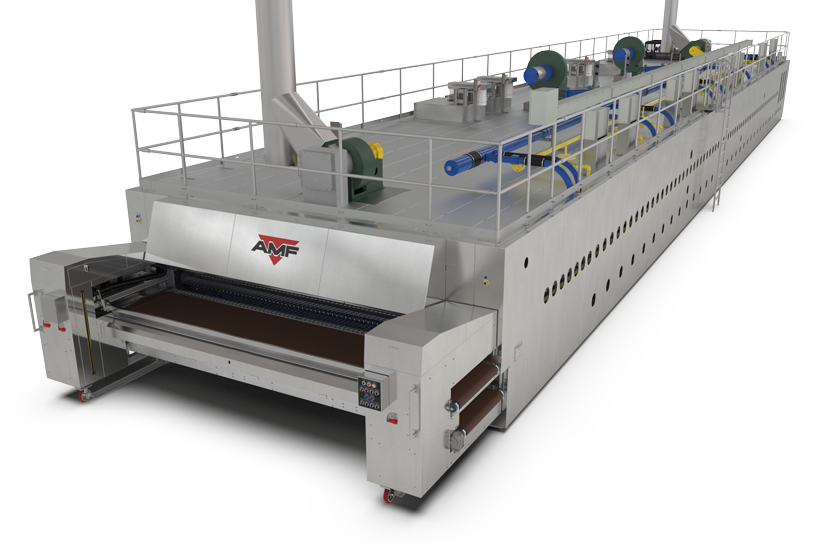

Direct-Fired Tunnel Oven

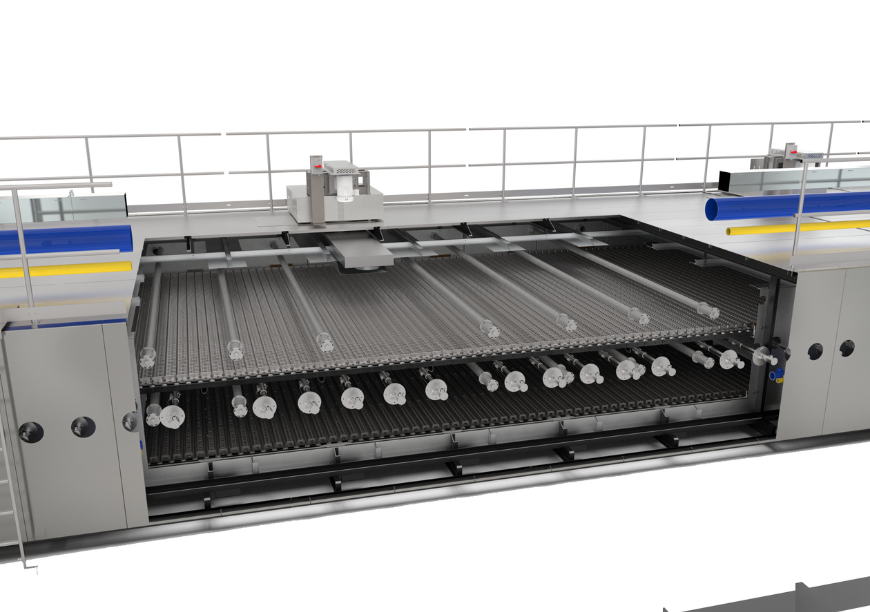

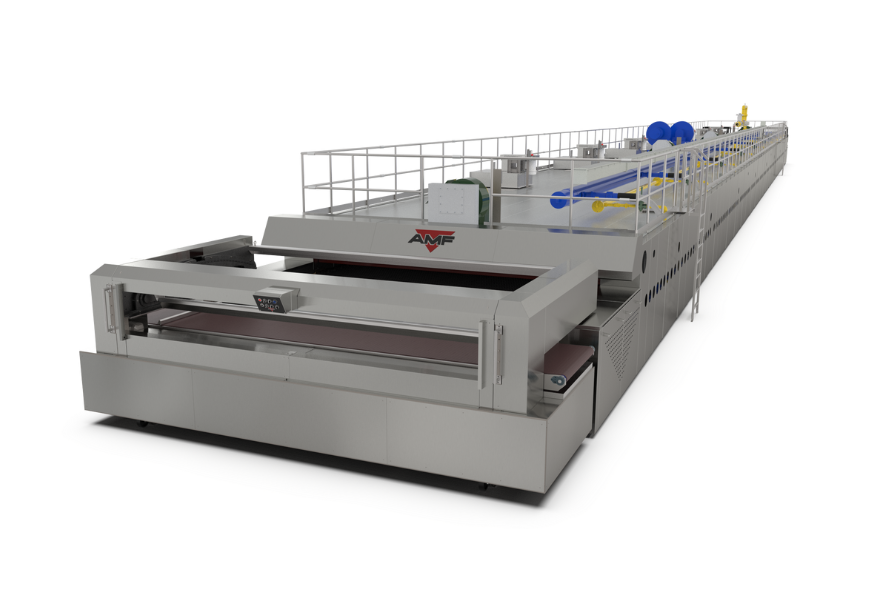

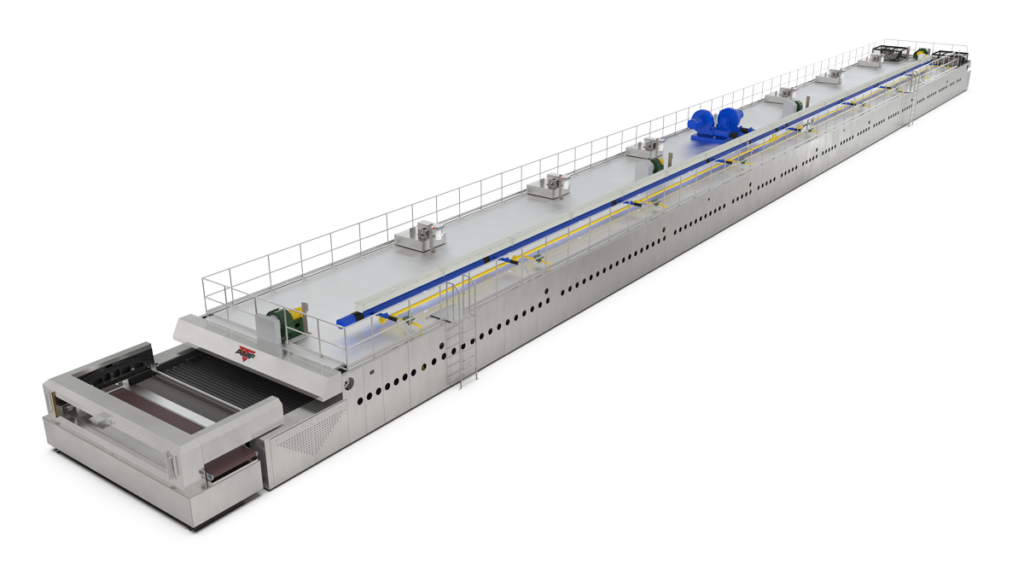

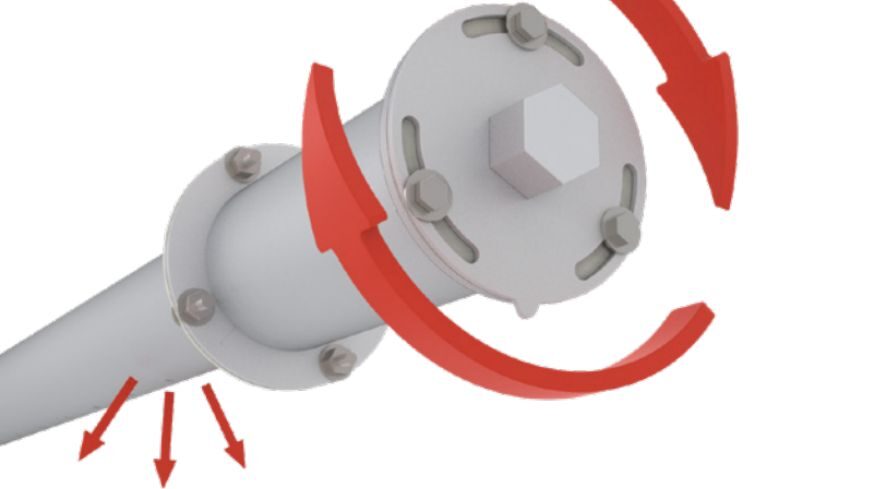

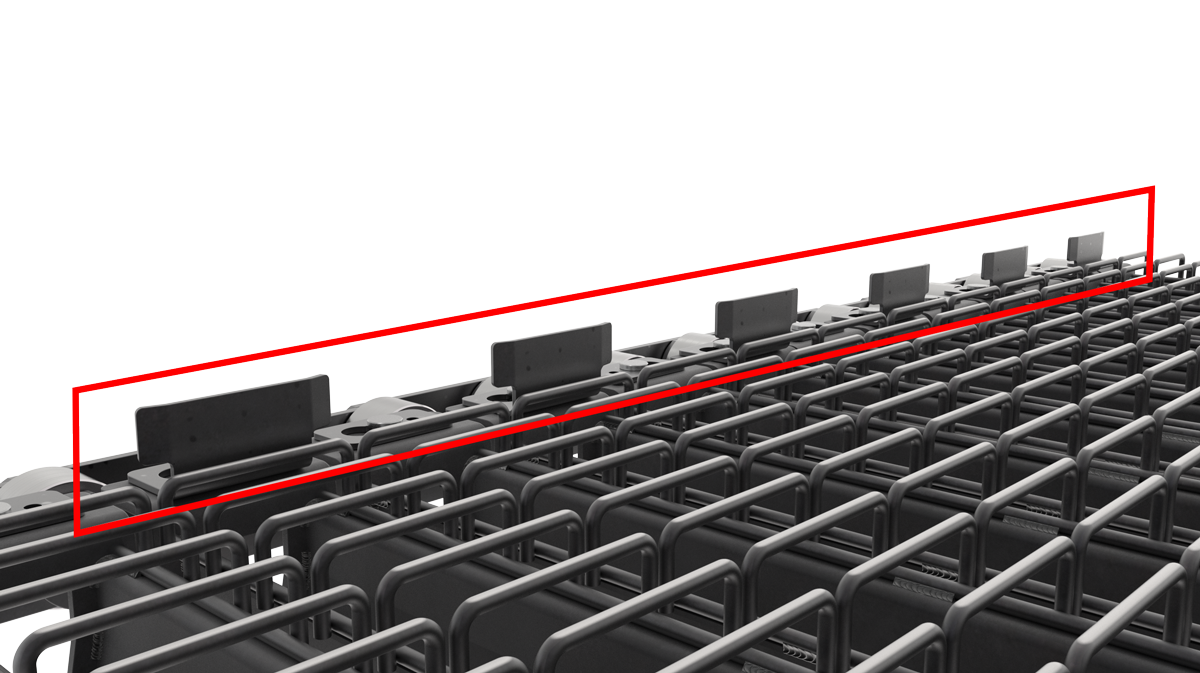

Built to last, the AMF Vesta Direct-Fired Tunnel Oven is a high-speed baking solution engineered with an exclusive orientable high-efficiency Coloraider system to increase the convection effect on each product at all times. A guardian chain management system maximizes chain life of this industrial tunnel oven.

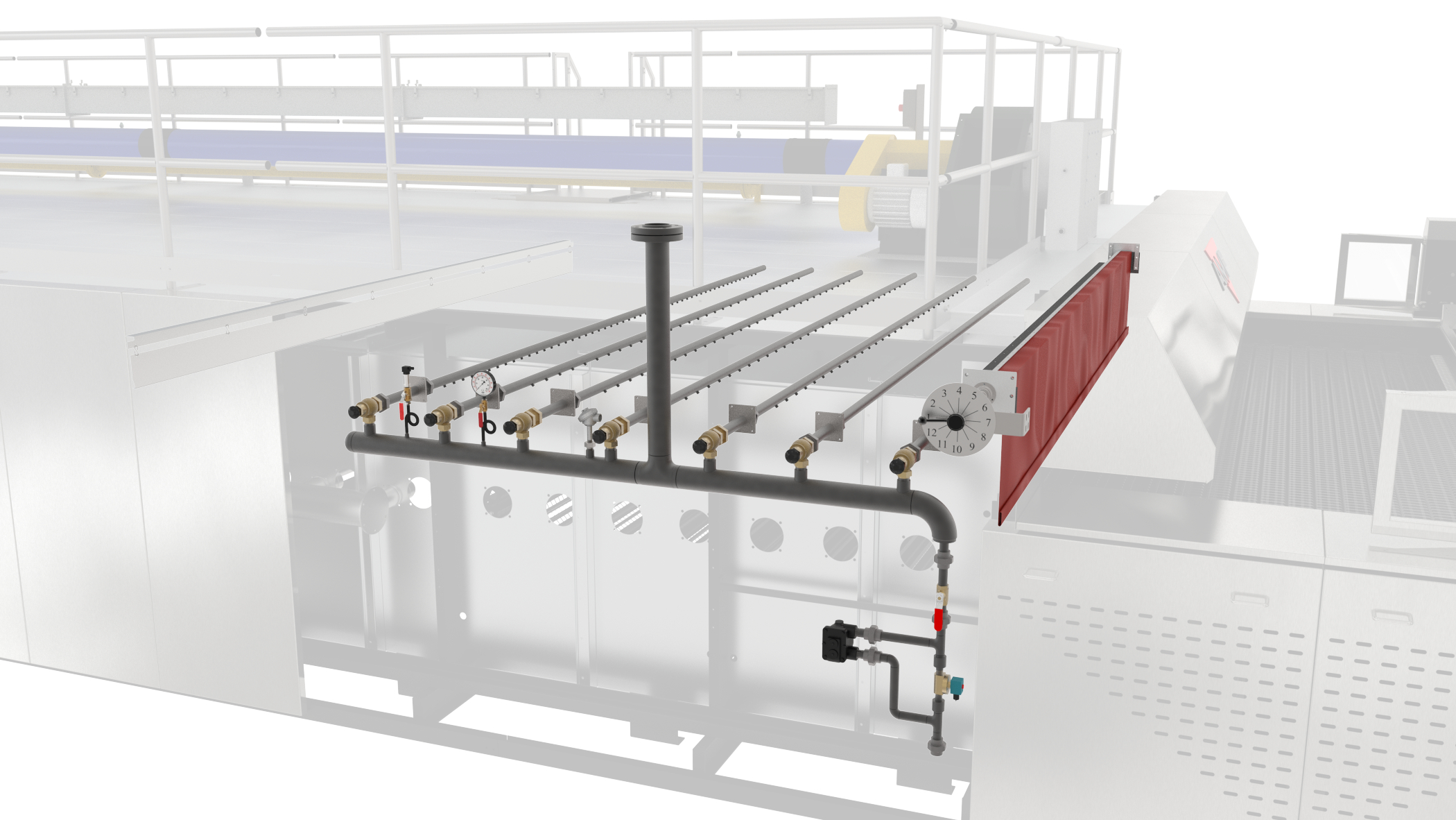

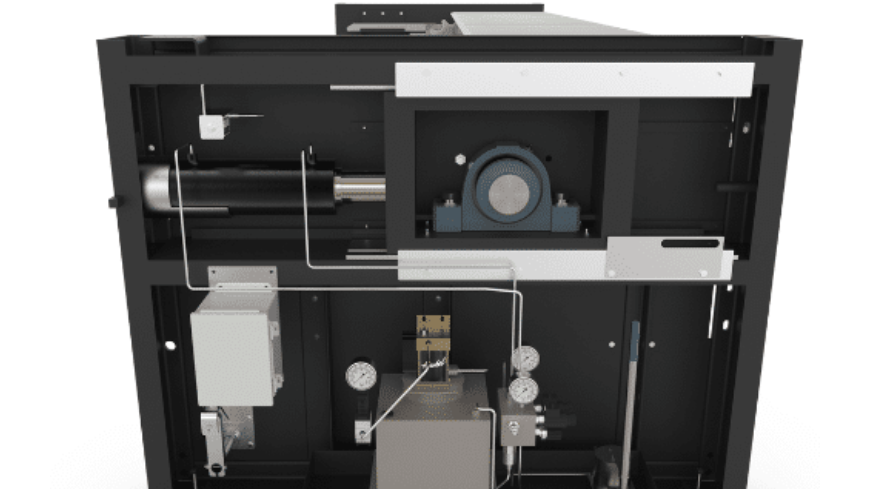

- Easy access main chain take-up tensioner with optional oven take-up monitoring ensures high-efficiency baking operation.

- Adjustable temperature control by zone to achieve optimal baking curves per products and constant airflow enable identical baking conditions.

- Computational fluid dynamics reduce cavitation and airflow turbulence to improve baking efficiency.

Additional Media

Visit Our innovation centers

Visit one of AMF’s Innovation Centers to test your recipes, formulate new products, or validate your processes on AMF Vesta baking equipment.

Complementary Equipment

Vesta Tray Oven Loader & Unloader

Our robust design, tailored for tray ovens, ensures side loading and unloading of bread and bun pans with unmatched accuracy and consistency, even at peak production rates.

More Proofing & Baking Equipment by AMF Vesta

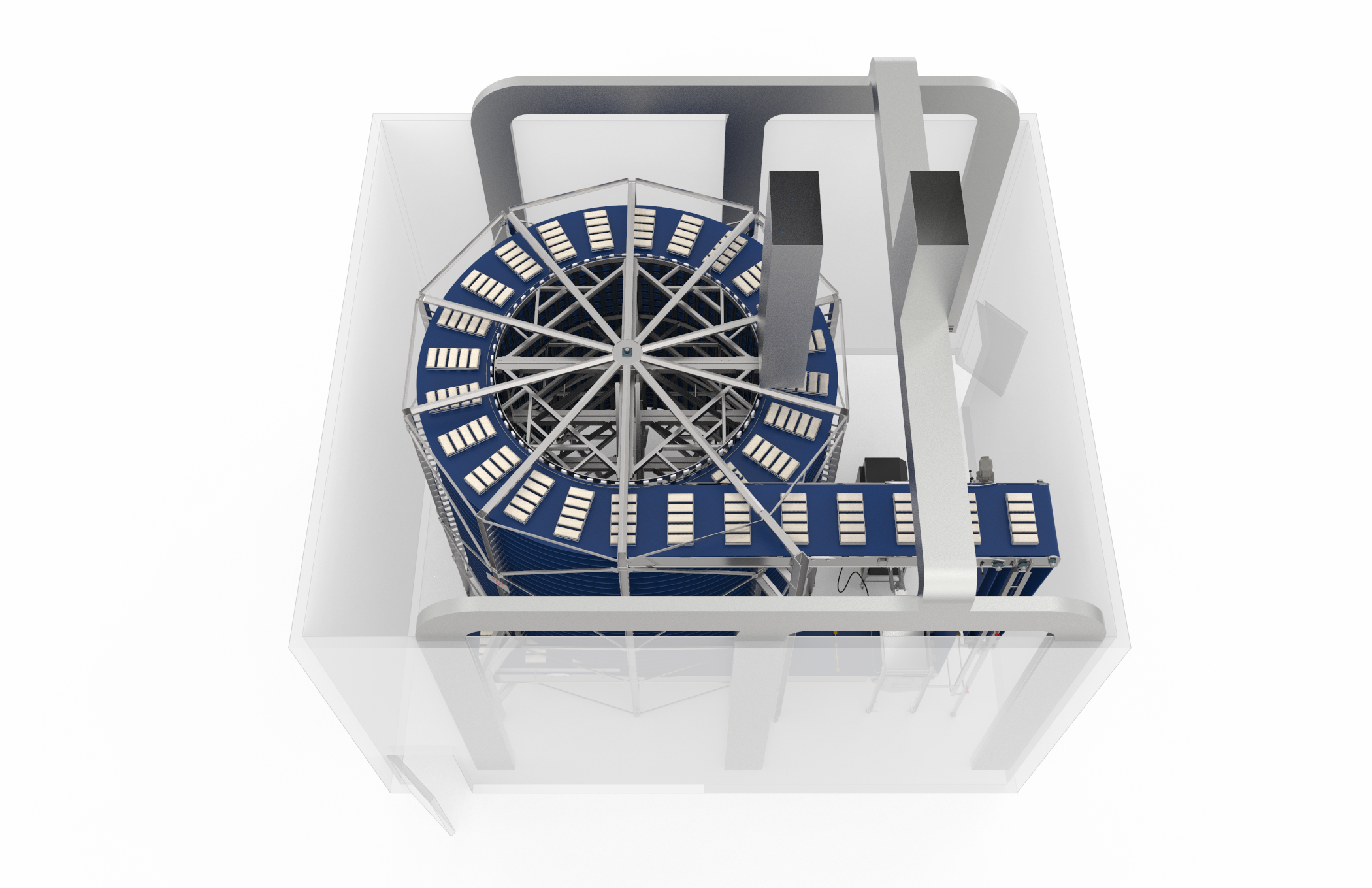

Spiral Proofer

Custom-configured, sanitary design with adjustable humidity and proofing times to improve proofing conditions in a continuous flow preserving final product quality.

Automatic Rack Proofer

Compact proofing solution for bread and buns suitable for limited floor space with the quantity of racks and shelves customized to suit each bakery’s unique production requirements.

Tray Oven

High-speed, compact baking solution with easily oriented, high-efficiency Coloraider system to increase the convection effect consistently on each product.

Relevant Resources

-

Electric Baking: Converting Industrial Ovens for Unparalleled Performance

As food consumers increasingly prioritize sustainability as a factor in their food choices, the commercial baking industry seeks innovative automation solutions to reduce the environmental impact…

-

5 Ways To A Sustainable Industrial Oven

More energy-efficient baking solutions are within reach for commercial bakers thanks to advances in digitalization and oven burner technology. It’s a welcome sight for an industry…

-

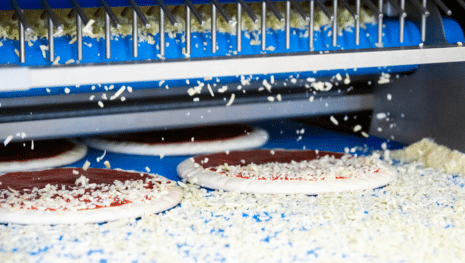

Baking Technologies For Pizza

According to Business Wire research, the global pizza market reached US$233 billion in 2023. With numbers like that, it’s easy to ask, “What’s the secret to…

Download the Vesta Direct-Fired Tunnel Oven BROCHURE

"*" indicates required fields