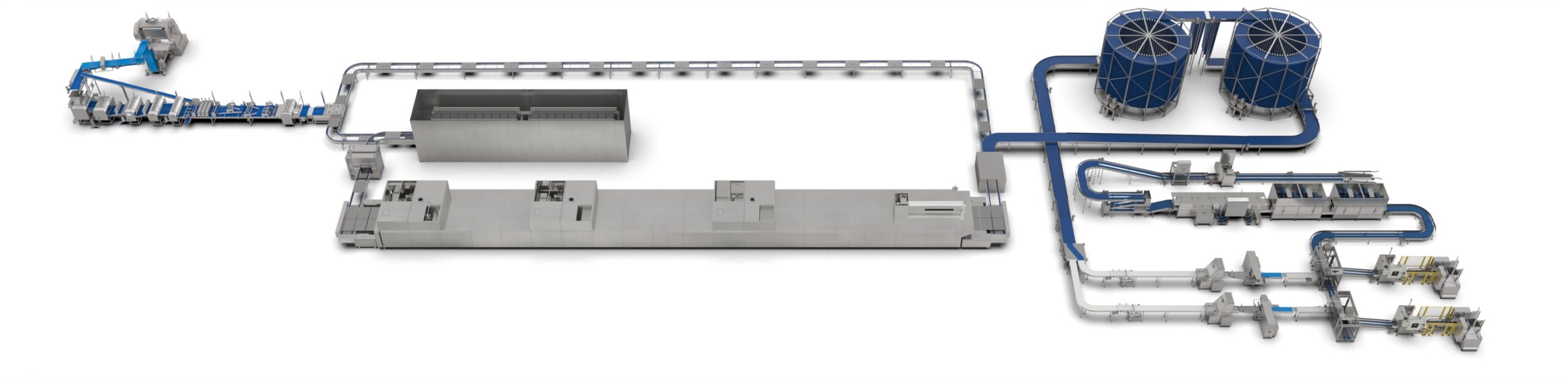

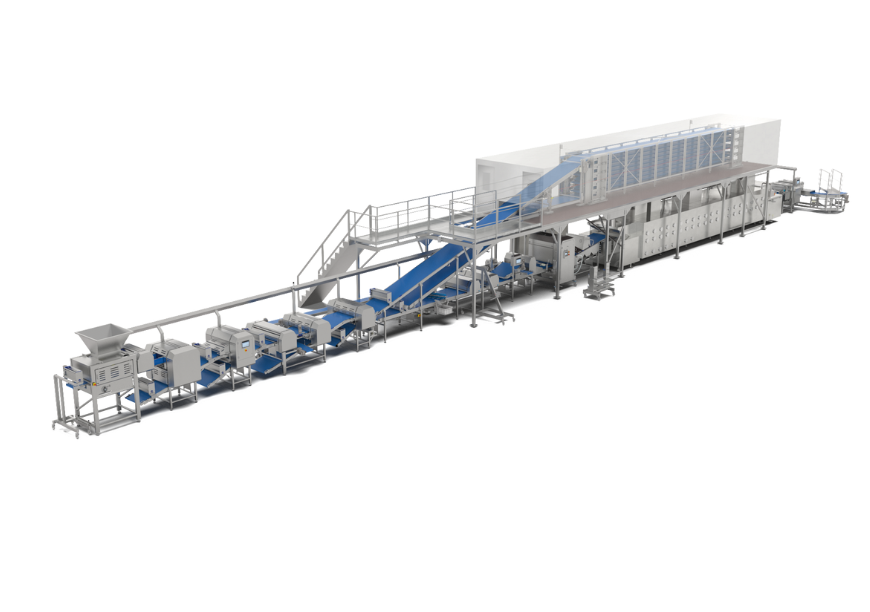

Tin/Swirl Bread System

AMF Bakery Systems specializes in swirl and tin bread production lines, offering solutions that redefine industry standards. Our systems are uniquely designed to produce consistently sheeted tin or toast breads and cinnamon swirl breads. These solutions maintain high quality and provide superior flexibility and optimal efficiency in your bakery operations. With the capability to produce up to 9,000 pieces per hour, our high-speed sheeting technology is tailored to meet the high-volume demands of modern bakeries, ensuring both efficiency and consistency in every batch.

Product Applications

Explore the Tin/Swirl Bread System

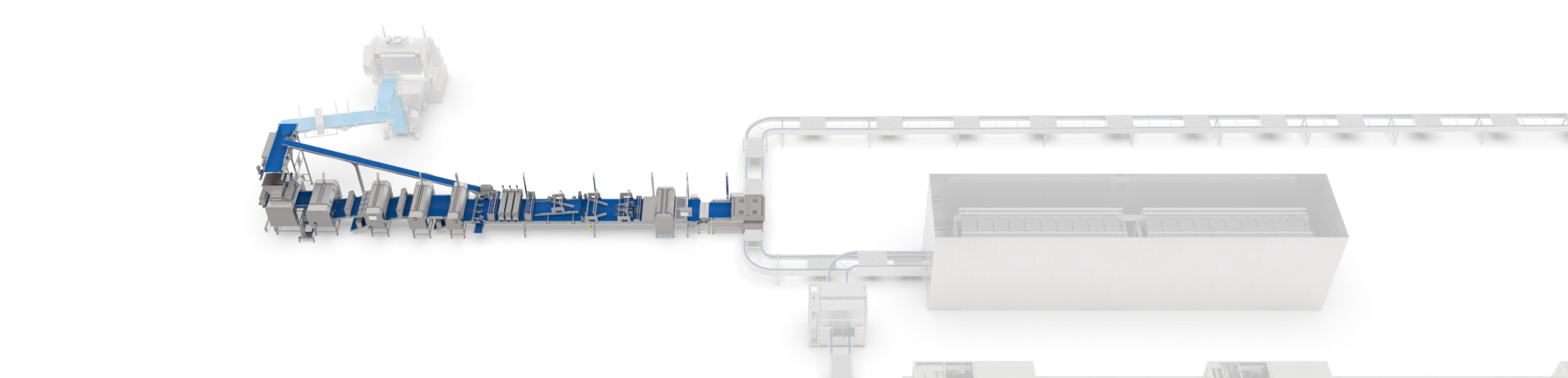

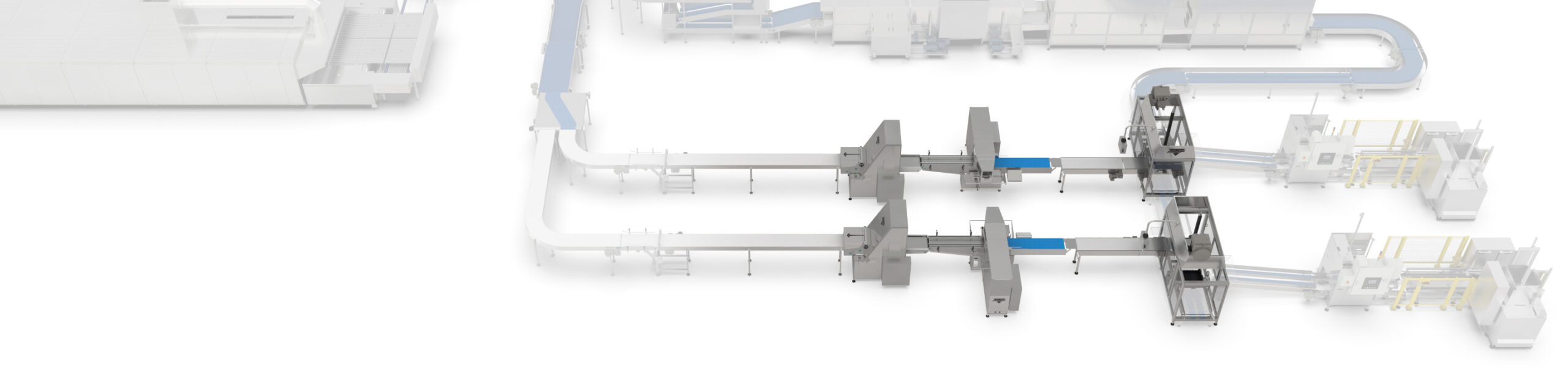

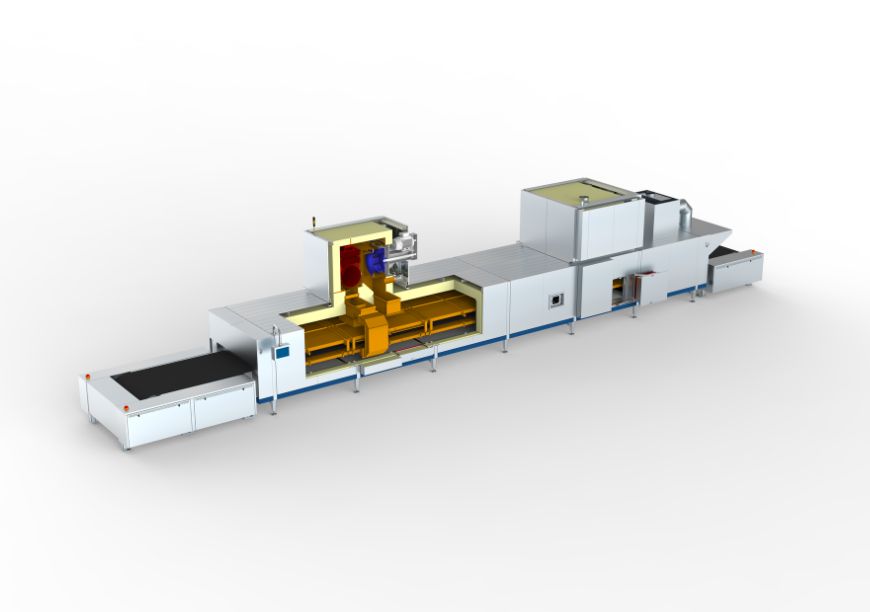

Make-up

Make-up

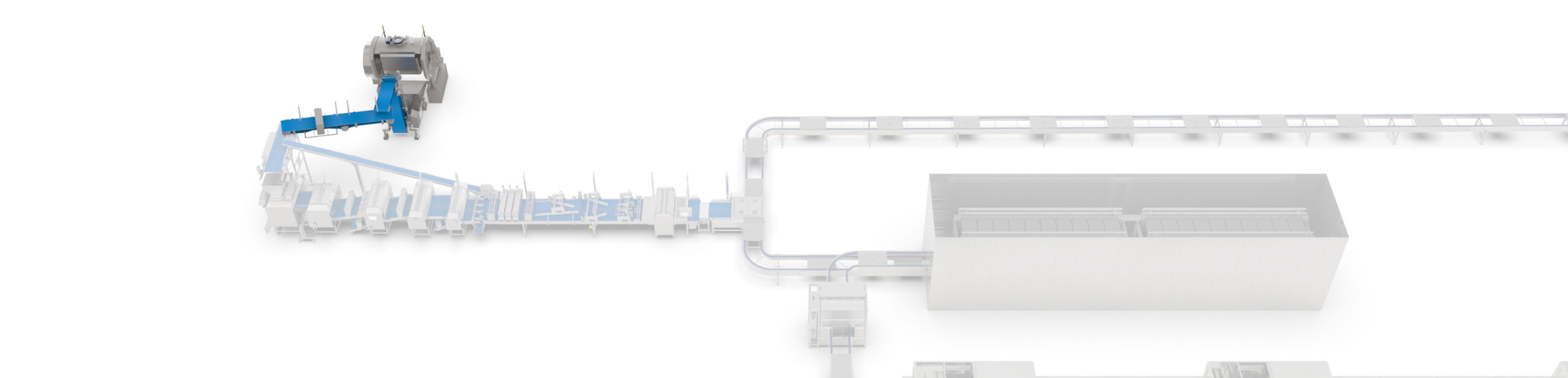

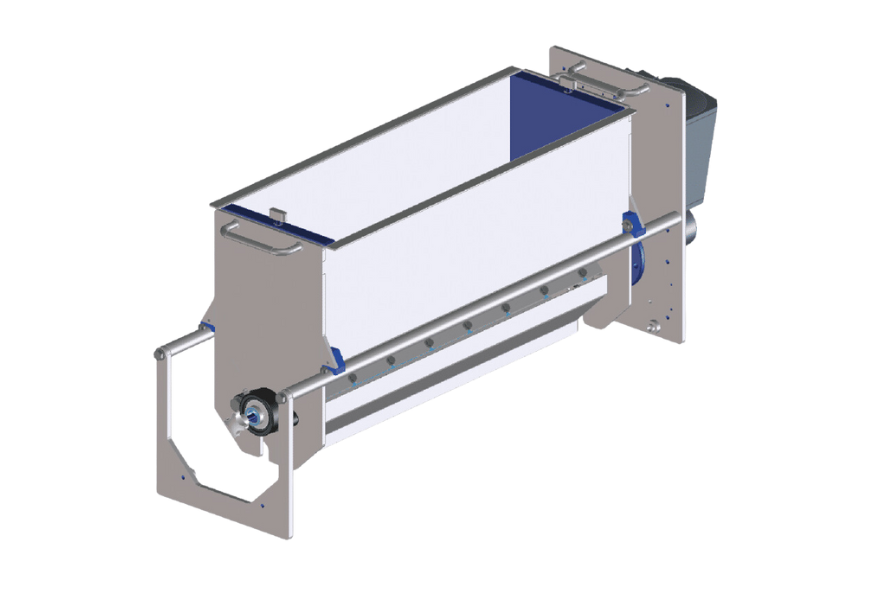

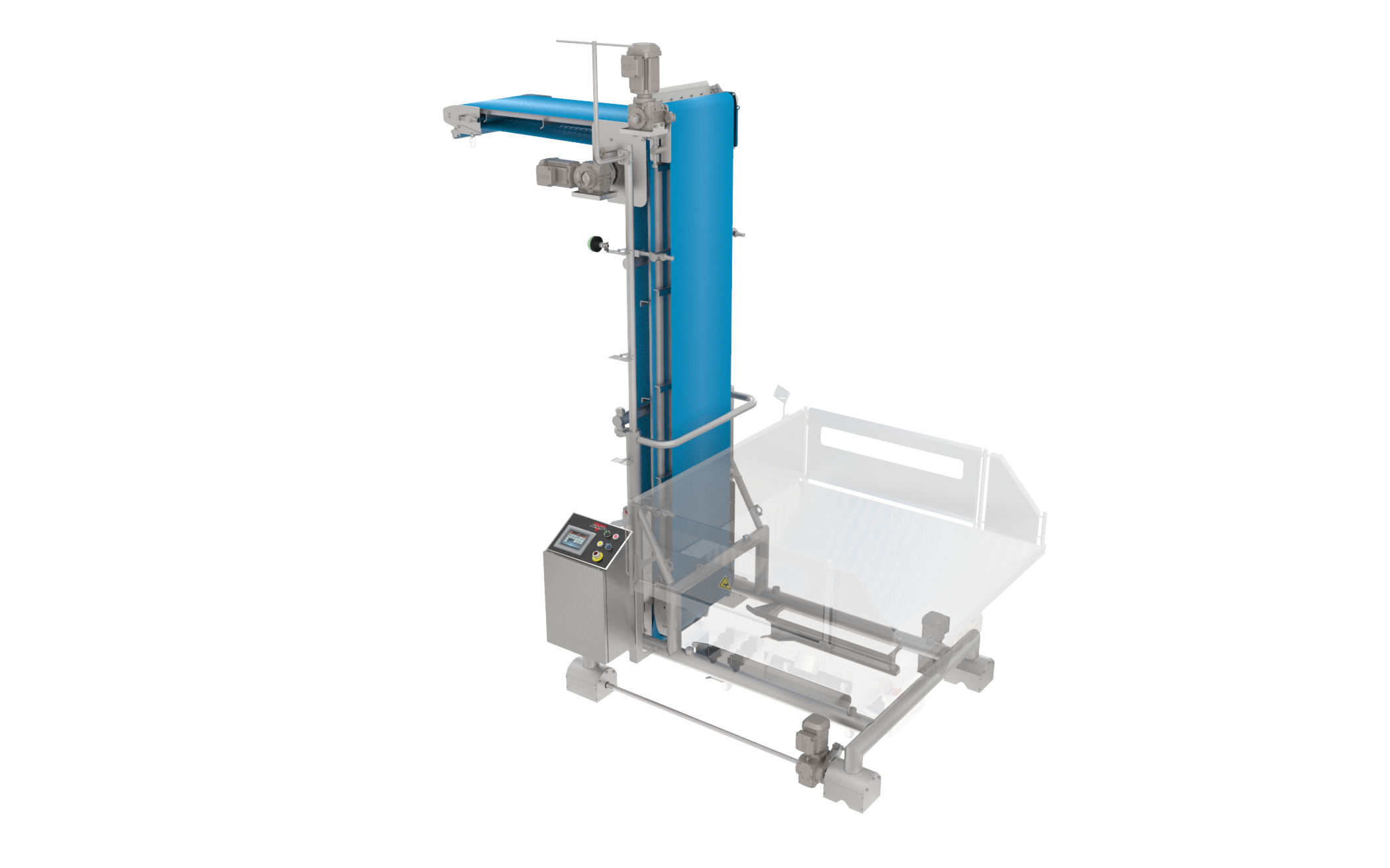

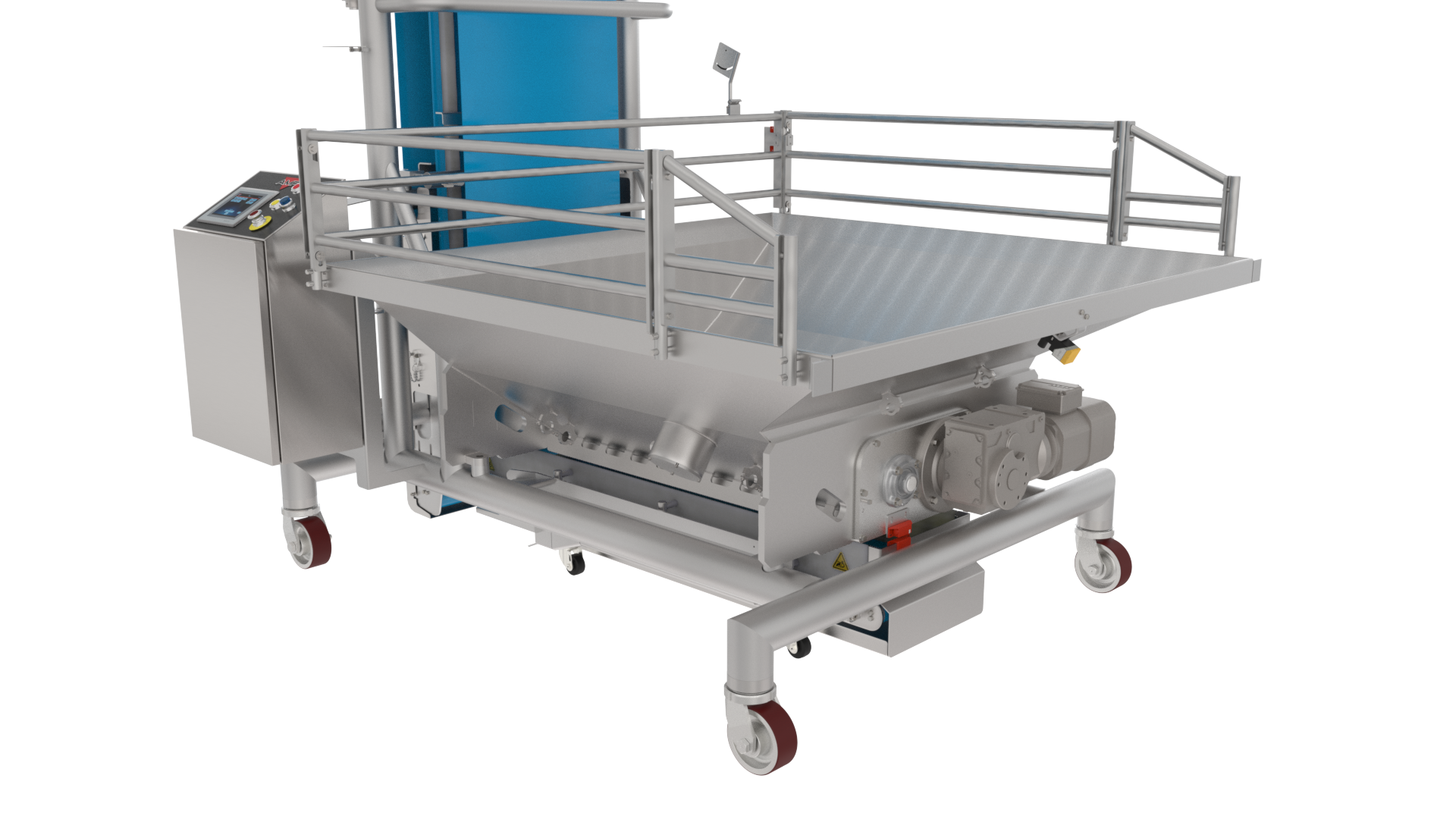

Mixing & Dough Handling

Mixing & Dough Handling

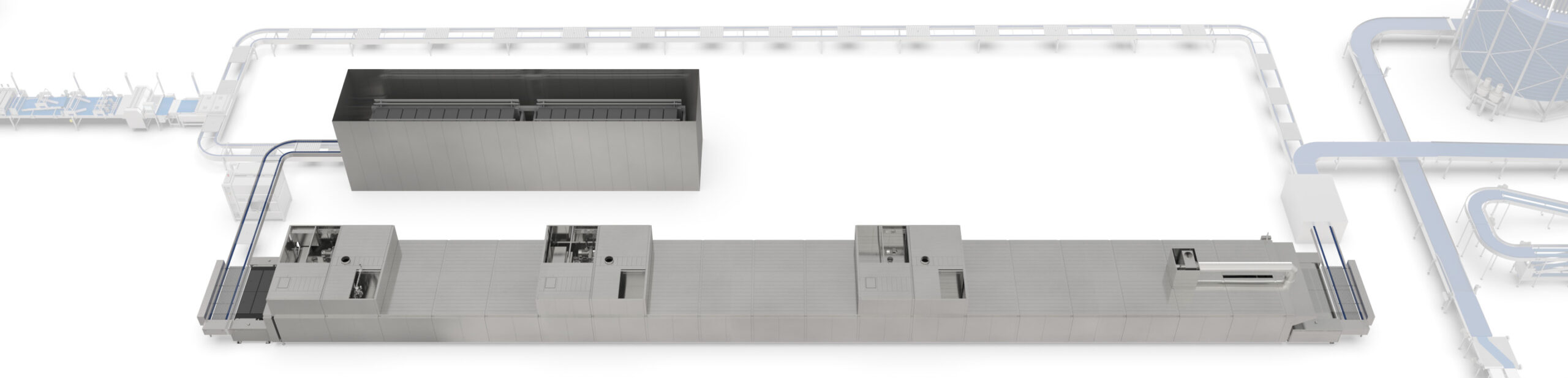

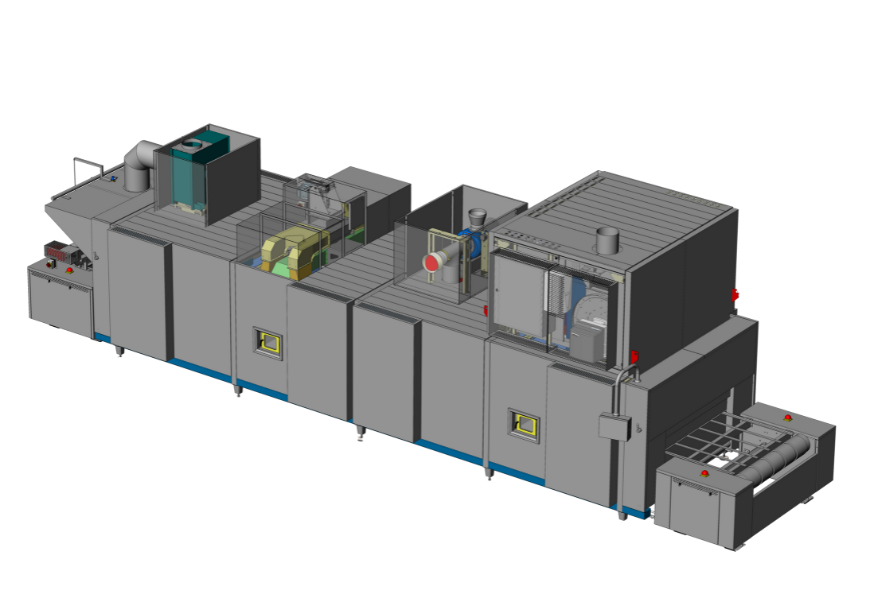

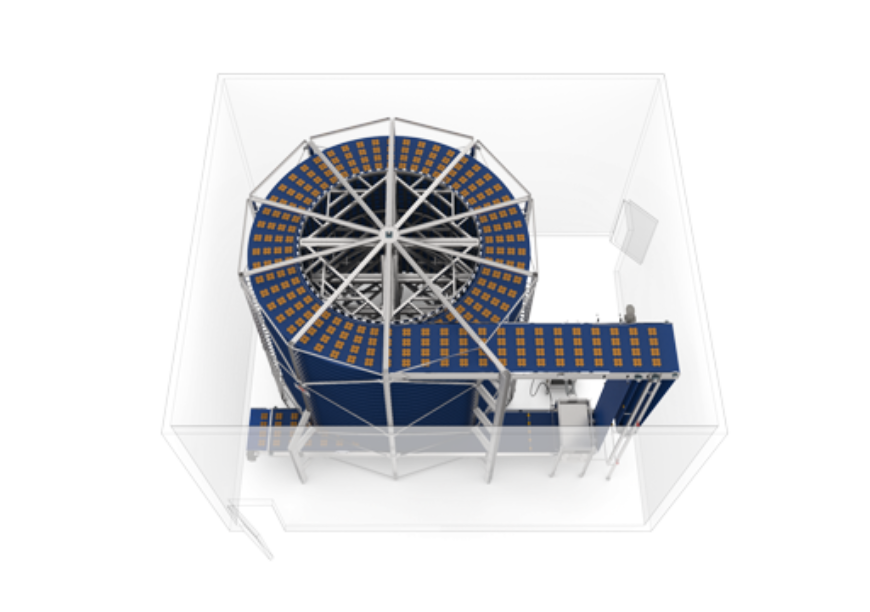

Proofing and Baking

Proofing and Baking

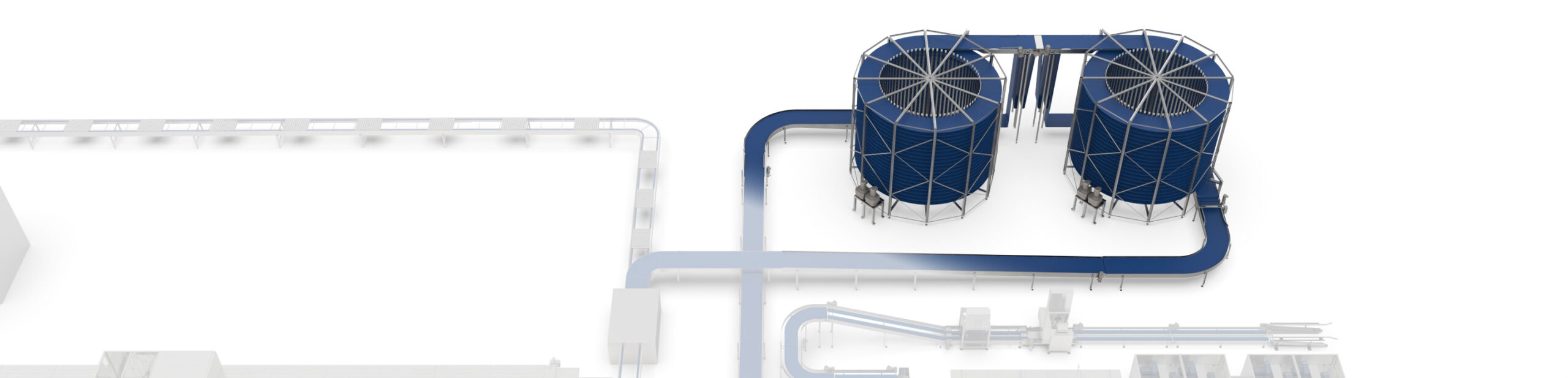

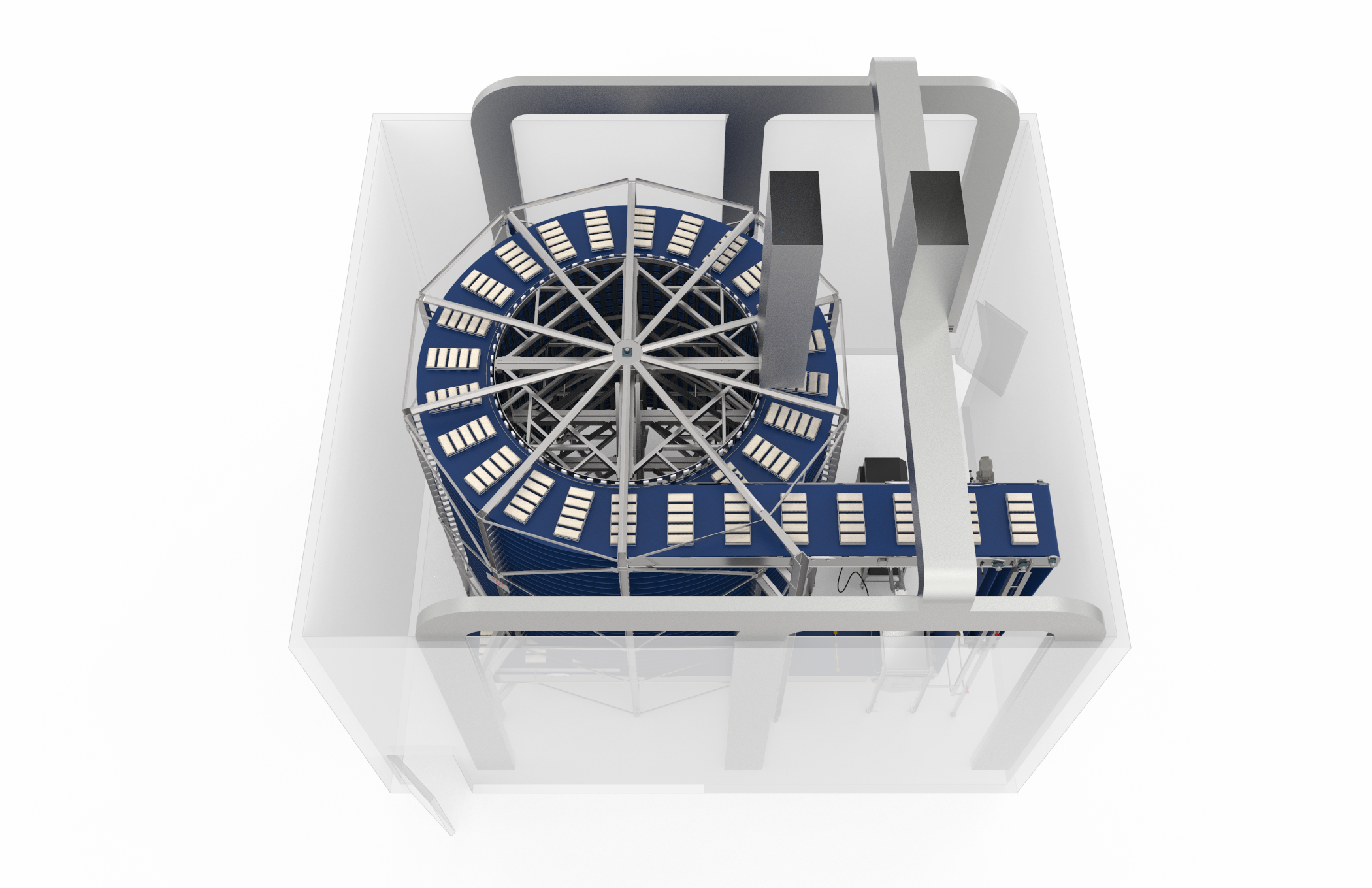

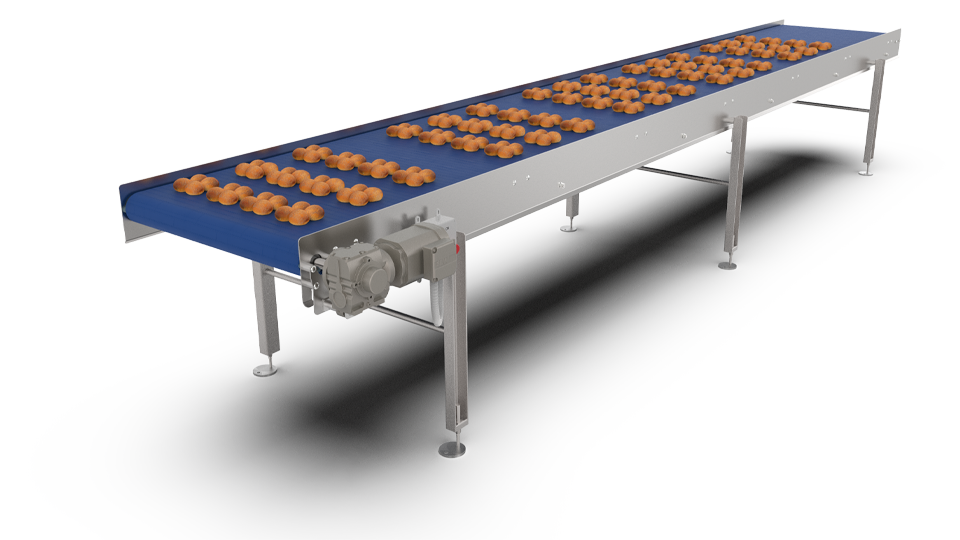

Cooling & Conveying

Cooling & Conveying

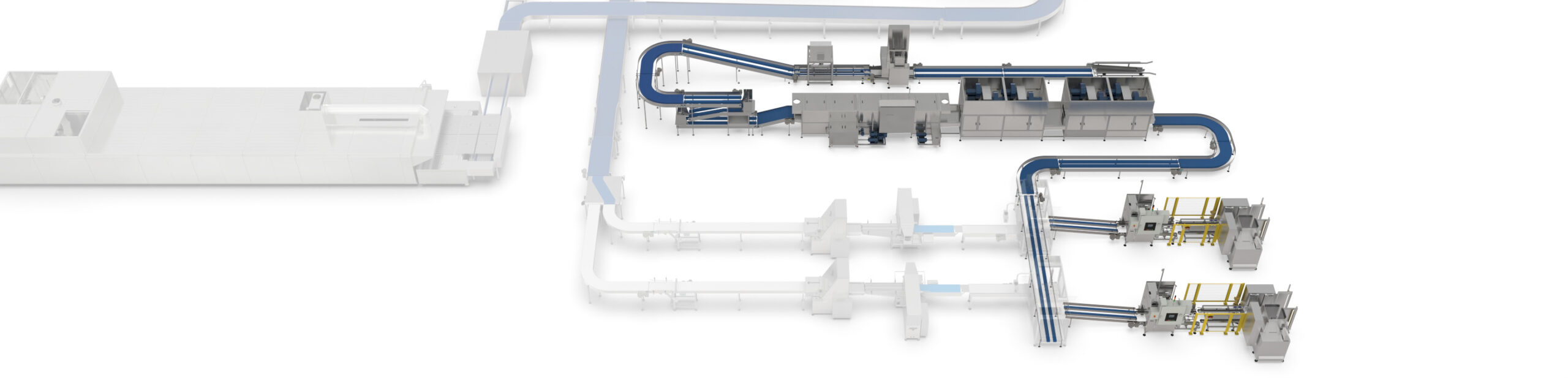

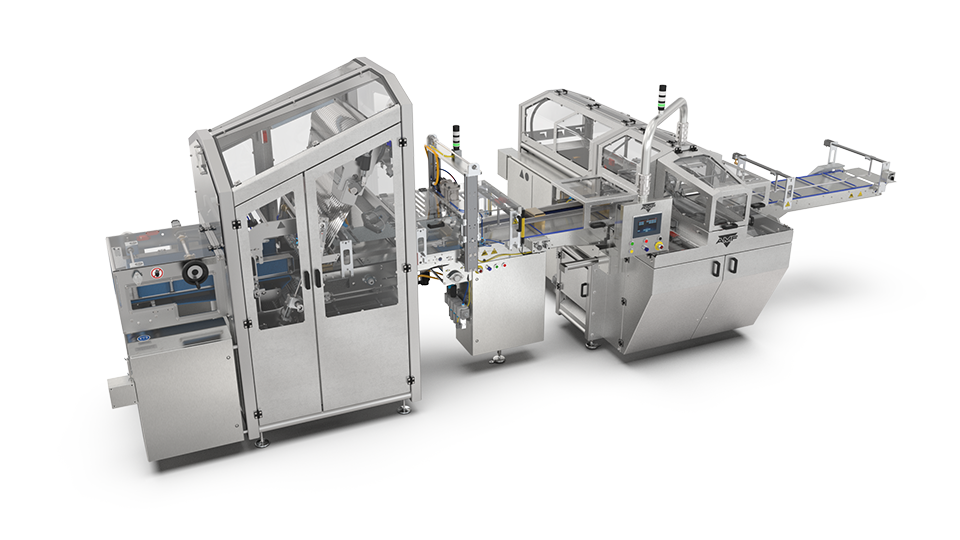

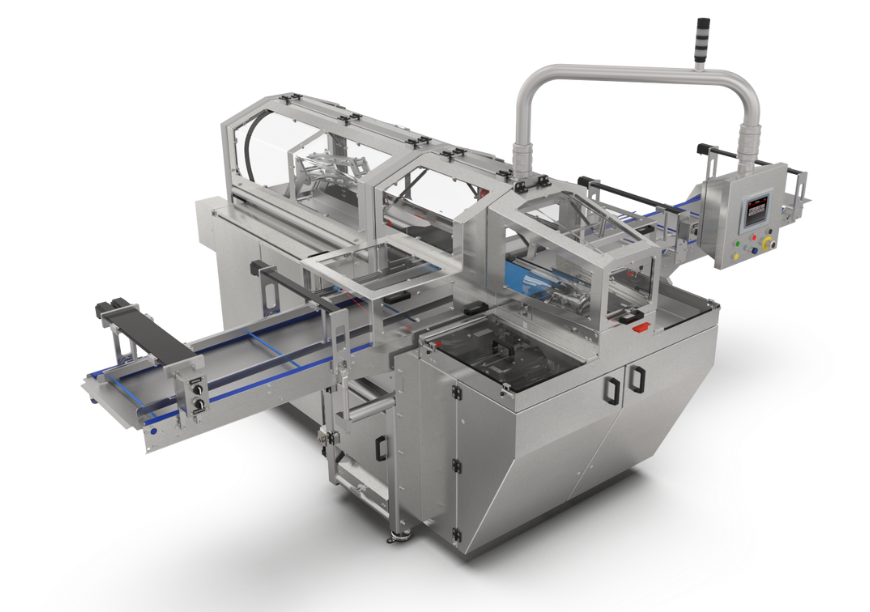

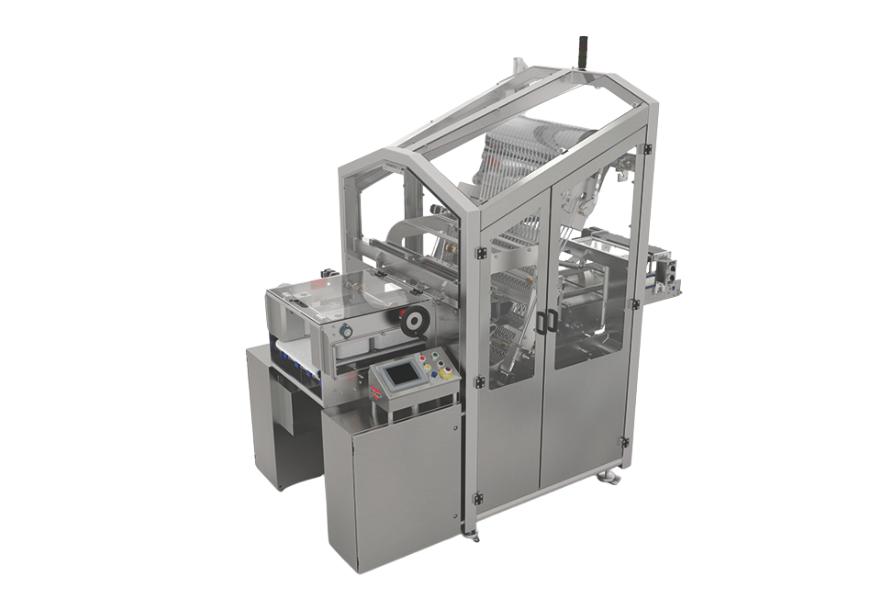

Packaging

Packaging

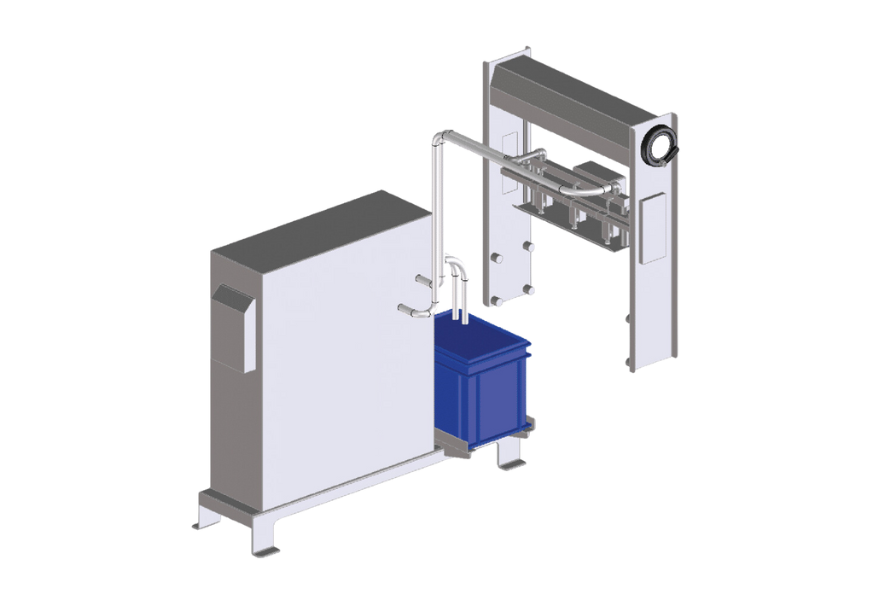

Post-Packaging

Post-Packaging

Click on a process area to view the recommended unit equipment below

Click on a process area to view the recommended unit equipment below

Process

Make-Up

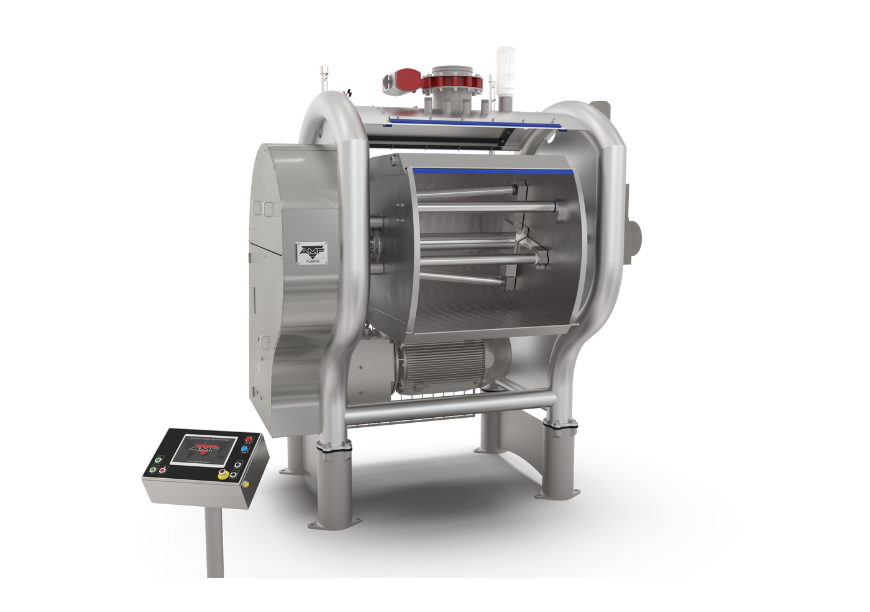

Mixing & Dough Handling

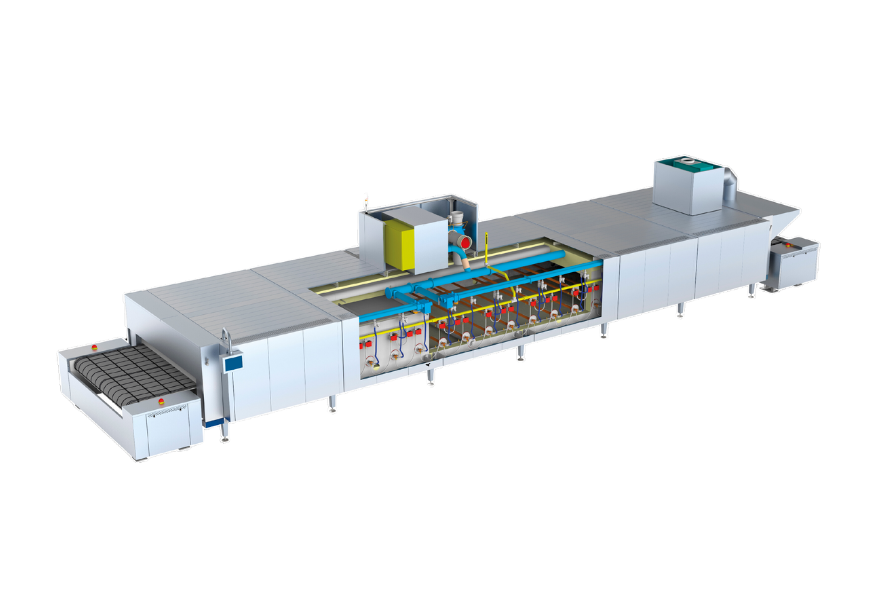

Proofing & Baking

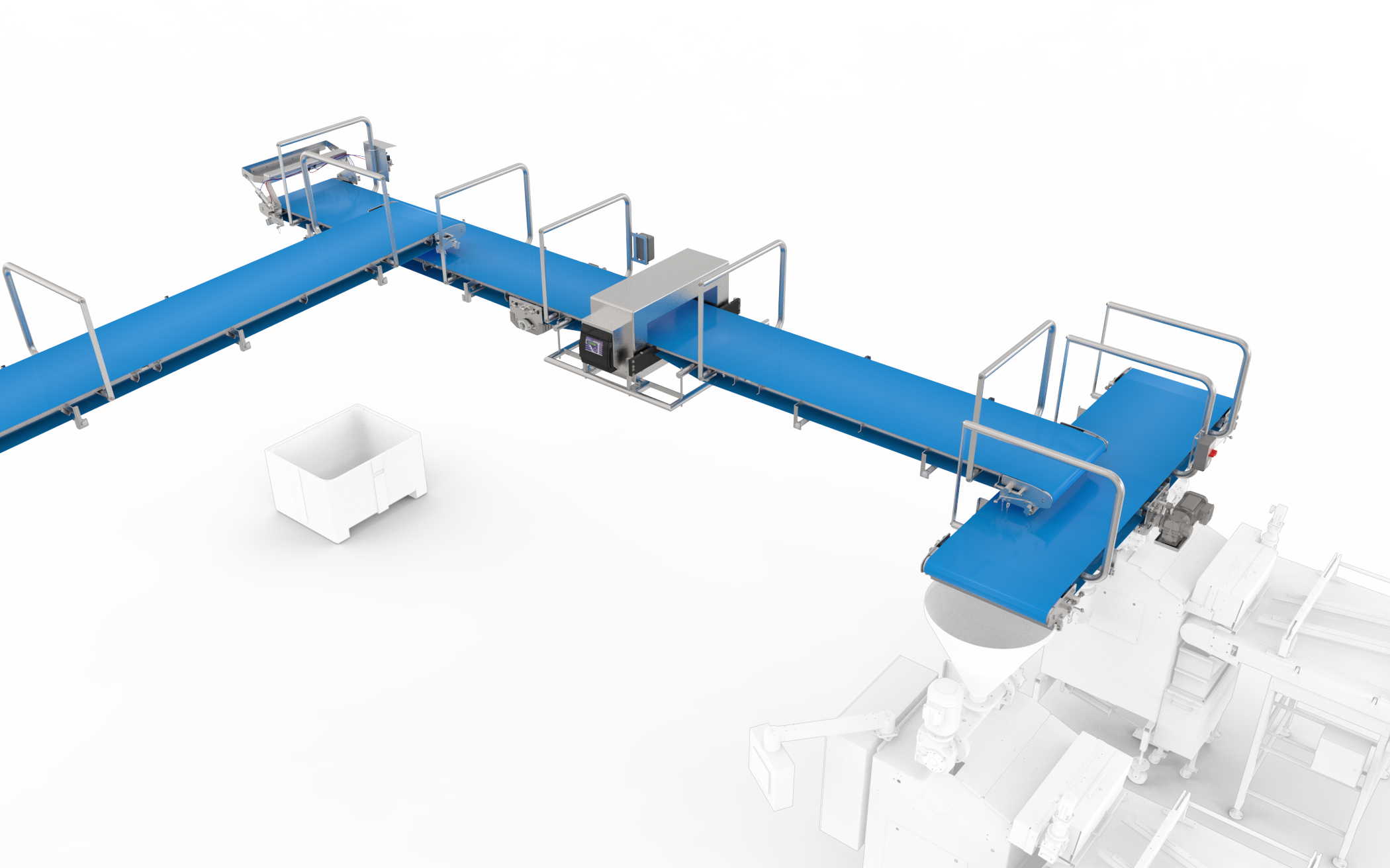

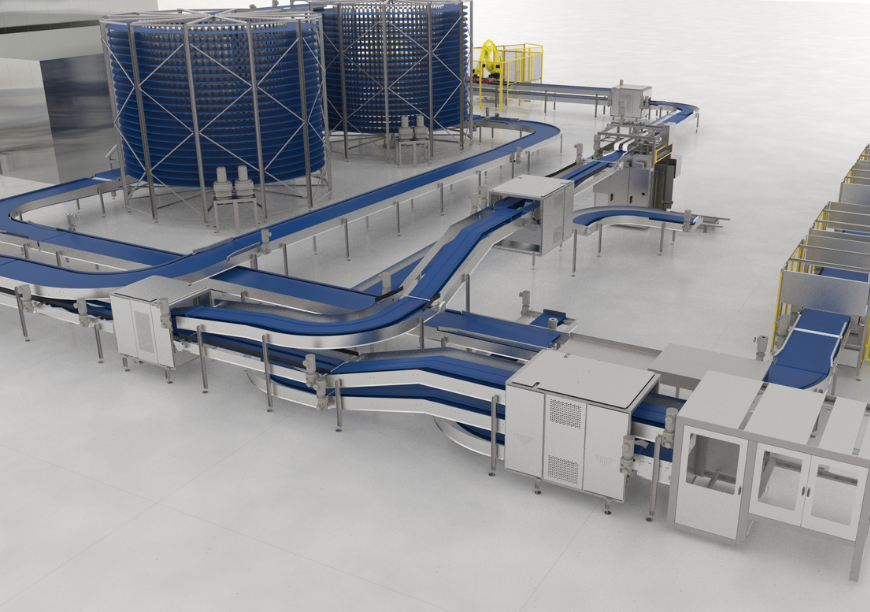

Cooling & Conveying

Packaging

Post-Packaging

Download the Artisan Bread System Brochure

"*" indicates required fields

Contact Our Artisan Bread Production Experts

From mixer to marketplace, we offer custom and turnkey solutions for bakeries around the world with dedicated project managers and responsive customer care representatives to ensure flawless execution and your bakery’s enduring success.