Hygienic Design for Allergen Management and Bakery Hygiene Rules Compliance

In the commercial baking industry, adhering to bakery hygiene rules is paramount. Effective allergen management and compliance with these rules are essential for consumer safety and satisfaction. At AMF Bakery Systems, we take hygienic design in our baking equipment seriously and strive to maintain the highest standards in hygienic design, ensuring adherence to sanitation rules and addressing allergen concerns with precision.

AMF’s Hygienic Design Solutions

AMF Fusion

At AMF, our vision is centered around working alongside our customers to produce better food while creating better lives for their teammates, families, customers, and communities. As a leading bakery equipment manufacturer, we’re committed to continuous improvement and fostering deep relationships with our clients, traits we consider essential in the commercial bakery equipment sector. Our success is measured by the success of the bakeries we serve, from small retail bakers to large industrial operations.

AMF Flex

Our AMF Flex line up is designed to meet the highest sanitation and allergen control standards for baking equipment. The equipment is easy to use, making cleaning and maintenance simple, and allowing bakeries to best follow bakery hygiene rules. AMF Flex’s dough rounding equipment is even built to eliminate the need for oil and dusting flour, which further simplifies sanitation practices and avoids introducing more potential allergens. AMF Flex designs also ensure consistent product quality, a key factor in maintaining consumer trust and meeting sanitation requirements.

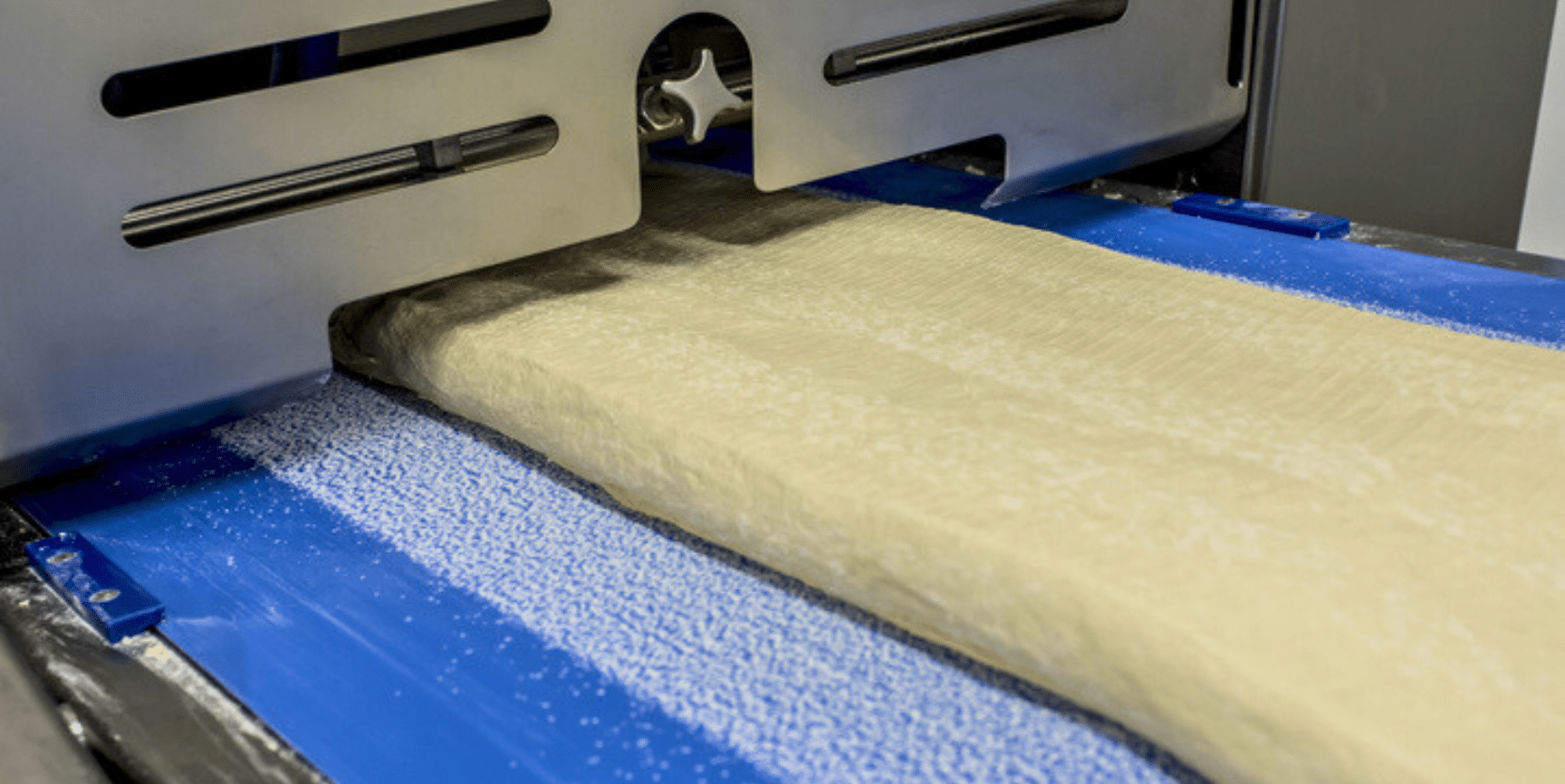

AMF Tromp

When it comes to sheeting, laminating, and decorating, AMF Tromp provides high-quality equipment engineered to meet hygienic requirements and allergen regulations for bakeries. AMF Tromp’s precision eliminates product waste, which can contribute to to poor sanitation in bakery systems. Like Fusion and Flex equipment, AMF Tromp is also designed to be easy to clean and maintain, further enhancing its sanitation capabilities to keep consumers safe.

AMF PackTech

AMF PackTech delivers sanitary systems tailored for retail bread and bun packaging as well as bulk packaging solutions. This ensures that the packaging process maintains high hygiene standards. PackTech’s automated solutions, such as the Saber 75 Bread Slicer, Mark 75 Bread Bagger, and the HS40 Bulk Bun Packer are designed with superior access design and corrosion-resistant stainless steel frames and guards to ensure high-quality production with ease of production changeover all while maintaining high hygiene standards. In addition, PackTech’s 75S is designed with the future in mind as it includes a full stainless steel sealed structure and stainless 304-4 guards with no holes in any tubing, ready for future bakery sanitation standards. All of these solutions, in addition to providing optimal sanitation, also produce consistent quality and extend the shelf life of bakery products.

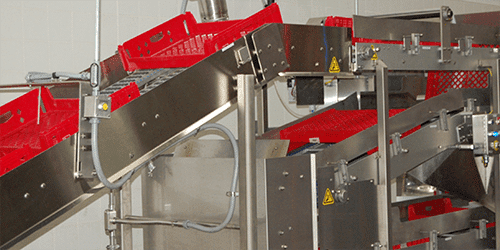

AMF Convay

AMF’s capacity to provide complete solutions for every part of the baking process is a significant benefit for those seeking comprehensive commercial bakery equipment. Unlike competitors who may focus on specific areas, we cover the entire baking process, from mixing to post-packaging, simplifying expansion into new product segments.

Consistent Quality and Sustainability

How the Lights Out Bakery Aids in Quality Consistency

When choosing a bakery equipment manufacturer, consider factors such as global presence, range of solutions, support systems, and a commitment to innovation and sustainability. If a bakery manufacturer has all of these characteristics, they will be equipped to help your bakery succeed today and well into the future. With AMF’s eye on innovation and baking for the future, we are well positioned as the premier baking partner of choice for growth-minded bakeries around the world.

Modernization and Repair: Meeting Bakery Hygiene Rules Efficiently

AMF’s repair and modernization teams play a crucial role in supporting whole plant modernization, ensuring that bakeries not only keep up with the latest technology but also remain in strict compliance with bakery hygiene regulations. Their expertise in upgrading and maintaining bakery equipment ensures that bakeries can operate at peak efficiency while adhering to the highest standards of hygiene. This commitment to modernization and repair is pivotal in helping bakeries meet the evolving demands of the industry, ensuring that they can deliver safe, high-quality products that comply with regulations.

Let AMF Support Your Bakery in Maintaining Compliance with Bakery Hygiene Rules and Bringing the Best Bakery Products to Market

Hygienic design and allergen controls are necessities when it comes to commercial baking equipment, not only for meeting sanitation regulations, but for satisfying consumers.

With solutions ranging from AMF Fusion to AMF Convay, and innovative concepts like the lights-out bakery, coupled with dedicated modernization and repair services, AMF is well-equipped to support bakeries in delivering allergen-free, hygienic products that comply with regulations. Trust AMF to be your partner in upholding bakery hygiene rules and elevating the standard of your bakery products.

Contact Your Baking Partner of Choice

From mixer to marketplace, we offer custom and turnkey solutions for bakeries around the world with dedicated project managers and responsive customer care representatives to ensure flawless execution and your bakery’s enduring success.