Q: How does AMF’s packaging equipment maintain product freshness and integrity?

At AMF, our packaging solutions prioritize the freshness and quality of bakery products from the oven to the consumer. Our Mark Bread Baggers utilize a…

The commercial baking industry is evolving rapidly, and bakeries are being pressed to deliver more with less. From labor shortages to safety risks, the hurdles bakeries face today demand smarter, more efficient solutions. What if there was a way to streamline your operations, protect your workers, and ensure your equipment lasts longer—all while reducing costs?

That’s where AMF Workhorse comes in. With a deep understanding of the commercial bakery landscape, AMF Workhorse, an AMF Bakery Systems brand, offers automated pan and lid handling solutions that allow bakeries to overcome today’s challenges and stay ahead in the future.

Facing Today’s Challenges Head-On

Running a successful bakery isn’t just about producing quality products—it’s about solving the operational puzzles that come with scaling your business. The daily grind of managing labor shortages, maintaining worker safety, and protecting valuable equipment can slow down your production and eat into your profits. Here’s how these challenges play out in bakeries and how AMF Workhorse solutions rise to meet them:

1. Labor Shortages and Efficiency: With a shrinking labor pool and increasing wage demands, bakeries are finding it harder to keep up with production demands. Manual pan handling can be tedious and time-consuming, limiting your ability to scale.

AMF Workhorse’s automated systems relieve the burden of pan management by taking over these repetitive tasks, increasing production throughput and minimizing reliance on manual labor. By streamlining pan handling and storage processes, your skilled workers can focus on higher-value tasks, boosting overall efficiency.

2. Worker Safety: Handling hot and heavy pans day after day poses significant safety risks for bakery workers. The physical strain and potential for injury can result in costly downtime and worker’s compensation claims.

AMF Workhorse’s automation solutions help to alleviate these risks by automating the handling of hot and cumbersome pans. This not only reduces the risk of injury but creates a more ergonomic workplace, allowing your team to work faster and more safely.

3. Equipment Protection: Your pans and lids are valuable assets. Frequent handling can lead to damage and wear, driving up costs for replacements and repairs.

AMF Workhorse’s gentle, precise handling systems extend the life of your pans and lids by minimizing wear and tear, ensuring that they remain in good condition longer, and reducing the need for expensive replacements.

Smarter Solutions for Pan and Lid Handling

AMF Workhorse understands that bakeries need customizable solutions to stay competitive. Whether you’re looking for high-speed automation or more traditional handling methods, AMF Workhorse offers the right pan or lid stacking solution to fit your needs:

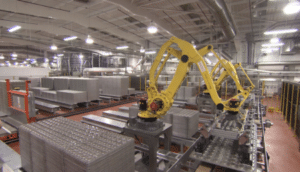

Robotic Pan or Lid Stacking System

Looking for a high-speed solution to streamline your pan handling process? The Robotic Pan Stacker and Unstacker uses a patented soft-touch end-of-arm tool to gently and accurately stack pans or lids, minimizing damage and ensuring long-term equipment reliability. This system can handle multiple pans or lids per cycle and integrates seamlessly with automated storage and retrieval systems or hand truck systems.

Gantry Pan or Lid Stacking System

Are you looking for a simpler robotic solution without multi-directional movement? The Gantry Pan Stacker and Unstacker is a comparable robotic solution that moves along a predefined linear axis and is mounted on a ridged, robust frame. The gantry system offers a simpler, yet reliable, automated solution suited for tasks that don’t require a wide range of motion.

Servo Magnetic Pan or Lid Stacking System

For bakeries that don’t require the high-speed versatility of a robotic system, the Servo Magnetic Pan Stacker and Unstacker provides a solution for bakeries still looking to automate their pan or lid handling processes. This system automates the receiving, stacking, and discharging of pans or lids with servo-driven precision, ensuring reliable performance even in the most demanding environments. Its compact design makes it an ideal solution for bakeries with limited space, maximizing automation efficiency without compromising on performance.

Storage and Retrieval Solutions for Every Bakery

Whether your bakery is ready to embrace full automation or prefers a more hands-on approach, AMF Workhorse has storage and retrieval solutions that fit your needs and can easily integrate with any range of pan handling systems.

Automated Guided Vehicles (AGVs)

For bakeries ready to enhance automation further, AGVs offer precision transportation of heavy loads, with omni-directional wireless technology, optimizing transport routes and boosting safety and efficiency. They follow a programmed route, using sensors and guidance systems to navigate the facility.

Automated Storage and Retrieval Systems (ASRS)

For those bakeries requiring high-density storage, AMF Workhorse’s ASRS systems provide efficient and reliable pan, lid or container storage, minimizing wear and reducing downtime. These systems typically involve a robotic system or crane that moves within single or multi-level racking or shelving structures to retrieve or store items.

Fixed Storage Location and Pan Trucks

If full automation feels like too much of a leap, Fixed Storage Locations and Pan Trucks provide a more familiar, hands-on approach to managing pan storage and movement. These options deliver a practical solution that integrates smoothly with your current workflow, offering flexibility for bakeries that aren’t ready to adopt fully robotic systems.

A Strategic Partner for Growth

At the end of the day, AMF Workhorse isn’t just about providing bakery equipment—it’s about providing solutions. Solutions that allow you to scale your bakery, reduce costs, while protecting your workers and equipment. Whether you’re just starting your automation journey or are looking to optimize existing processes, AMF Workhorse has the right tools to help you succeed.

Ready to transform your bakery operations? Contact AMF Workhorse’s team of automation experts today to explore how our pan and lid handling solutions can seamlessly integrate into your production process, enhancing safety, efficiency, and reliability for your bakery’s enduring success. Get in Touch.

At AMF, our packaging solutions prioritize the freshness and quality of bakery products from the oven to the consumer. Our Mark Bread Baggers utilize a…

Yes! In fact, all of our bakery packaging equipment is customized to facilitate seamless synchronization with upstream and downstream processes. We are dedicated to meeting…