Q: How does AMF’s packaging equipment maintain product freshness and integrity?

At AMF, our packaging solutions prioritize the freshness and quality of bakery products from the oven to the consumer. Our Mark Bread Baggers utilize a…

Commercial bakeries face increasing pressure to deliver more with fewer resources. From managing labor shortages to ensuring product quality and maintaining operational efficiency, these challenges demand innovative solutions. AMF Workhorse, an AMF Bakery Systems brand, offers a suite of Product Loading Solutions designed to streamline operations, reduce dependency on manual labor, and ensure products are handled with precision and care. Workhorse’s Robotic, Gantry Robotic, and Mechanical Product Loaders offer a scalable approach, enabling bakeries to meet today’s challenges while preparing for future bakery growth.

Bakeries operate in an environment where every second counts. Finding operators, production bottlenecks and product damage can disrupt operations and impact profitability. AMF Workhorse solutions are designed to address these challenges head-on, ensuring that bakeries can scale efficiently:

Labor Shortages: The commercial bakery industry continues to struggle with labor shortages, leading to higher operating costs and production delays. Manual loading processes are labor-intensive, requiring significant time and workforce.

AMF Workhorse Product Loaders automate repetitive, labor-heavy processes, allowing bakeries to maintain consistent throughput with fewer employees. This shift enables businesses to reduce operational costs and redirect skilled workers toward more valuable tasks.

Product Quality: Manually loaded products are at higher risk of damage during handling and packaging, leading to wasted goods and dissatisfied customers. Mishandled products can result in tears, misaligned packaging, and rework.

AMF Workhorse automation ensures precise and gentle handling, significantly reducing product damage. For example, the VersaLoader system uses a suction-cup end-of-arm tool to ensure products are precisely placed into containers without damage, preserving product and packaging integrity.

Efficiency Through Automation: Efficiency is key to bakery success, and slow or inconsistent loading processes can disrupt operations and increase costs. Manual handling introduces variability, leading to bottlenecks that impact production flow.

AMF Workhorse’s automated product loaders eliminate these inefficiencies, ensuring smooth and consistent product movement through the production line. Automated loaders with servo-driven technology and multi-infeed configurations keep operations running at optimal speed, meeting production targets while reducing downtime.

AMF Workhorse offers three levels of Product Loading Solutions, providing a range of automation options to fit every bakery’s needs:

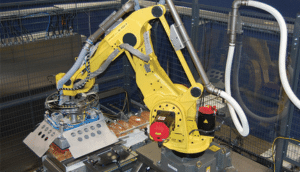

Robotic Product Loaders: AMF Workhorse’s Articulating Arm Loader (ABL) offers the highest level of automation, featuring multi-axis movement for maximum flexibility and speed. These loaders are ideal for bakeries handling multiple product types and high production volumes.

Gantry Robotic Product Loaders

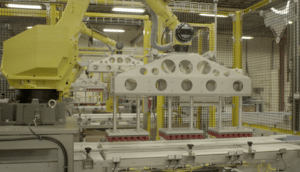

AMF Workhorse’s VersaLoader offers precision and adaptability, moving along pre-defined axes to meet varied product handling needs. It uses servo-controlled gantry robotic arms with quick-change End-of-Arm-Tools (EOAT) to pick, group, and compress products into containers. For bakeries seeking a balance between automation and space efficiency, the VersaLoader is an ideal solution. Additionally, there is an option to enhance the system with vision inspections and rejection capabilities, providing even greater accuracy and quality control.

Mechanical Product Loaders

AMF Workhorse’s Product Orientor Loader provides a reliable solution for repetitive loading tasks, using servo-driven movements to ensure smooth, quiet operation. With up to 30 pre-programmed patterns, this loader offers intuitive operator selection and low maintenance, making it an excellent fit for bakeries seeking straightforward automation.

Efficient Operation: Automates basic loading processes, reducing dependency on manual labor.

Durability: Built for long-term use with minimal downtime.

AMF PackTech Integration: The Bulk Bun Basket Loader integrates seamlessly with the PackTech HS40 Bulk Bun Packer, ensuring fast, accurate packaging of buns at scale.

Workhorse’s Product Loading Solutions seamlessly integrate with AMF PackTech packaging systems, enhancing the entire post-packaging process. This integration ensures smooth transitions between product loading, packaging, and handling, resulting in a cohesive, automated workflow. Whether it’s placing products onto packaging lines or preparing them for shipment, Workhorse loaders work in harmony with PackTech equipment to reduce bottlenecks and maintain production speed.

In addition, Workhorse loaders integrate seamlessly with post-packaging solutions such as container handling systems, ensuring efficient loading, stacking, and unstacking of containers for distribution. Bottom-Up Stackers and Bottom-Out Unstackers work alongside Workhorse loaders to streamline the movement of packaged products, maintaining product quality and improving efficiency across the entire operation.

Take the Next Step Toward Automated Product Loading

Automation is more than just an investment in equipment, it’s an investment in the future of your bakery. With AMF Workhorse Product Loading Solutions, you’ll gain a strategic partner that creates a seamless, automated workflow for your packaging and post-packaging processes.

Why Partner with AMF Workhorse?

Ready to elevate your bakery operations? Contact us today to explore how our Product Loading Systems can help you ensure efficiency, product quality, and operational excellence. Get in Touch

At AMF, our packaging solutions prioritize the freshness and quality of bakery products from the oven to the consumer. Our Mark Bread Baggers utilize a…

Yes! In fact, all of our bakery packaging equipment is customized to facilitate seamless synchronization with upstream and downstream processes. We are dedicated to meeting…