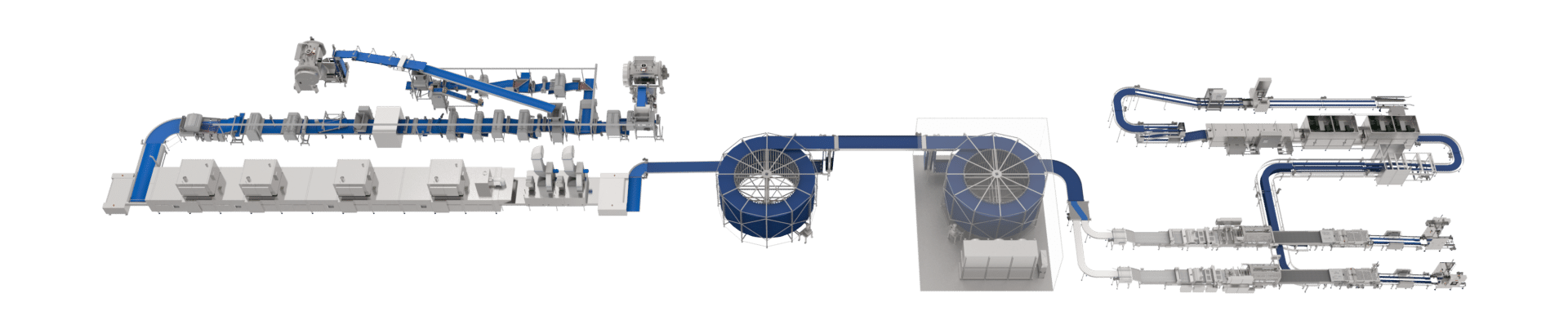

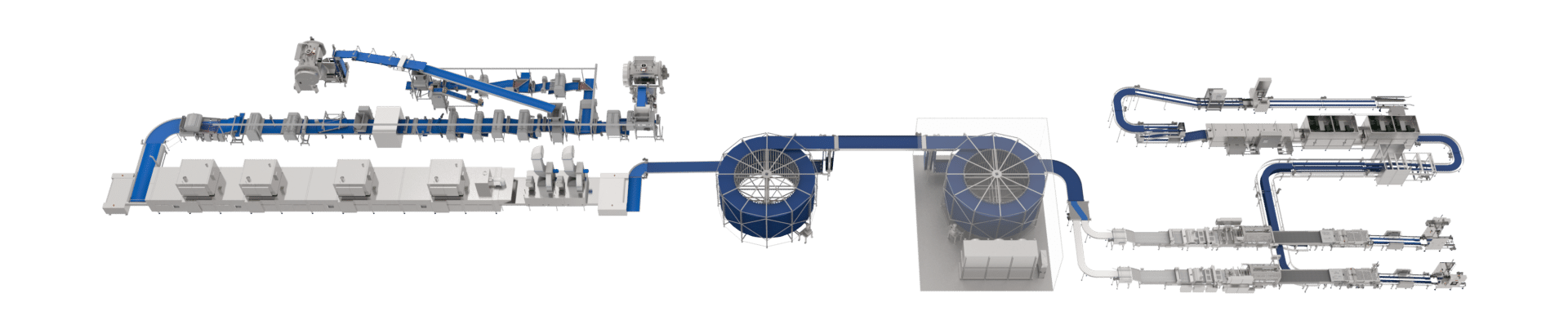

Handheld Bread Production Systems:

Filled Snack Bread Solutions

THE TURNKEY SOLUTION for reliable operations, consistent quality, increased safety, simple operations, increased efficiency, and seamless integration in your filled snack bread production system.

Increase production capacity, uniformity, and quality with the gentle handling bread snacks require with AMF’s best-in-class sheeting and laminating systems. With complete system solutions that help you control every aspect of the baking process, AMF’s scalable technologies help you achieve delicious filled snack products.

Click to expand

Click to expand

Click to expand

Click to expand

SIMPLE MONITORING FOR

BETTER, FASTER DECISIONS

AMFConnect™ ensures the best performance from your bakery’s production line by providing access to the most advanced integrated, real-time bakery system data and unit equipment information. Access to critical operational information allows your team to make better, faster decisions improving operations and efficiency throughout your bakery.

Open Frame Mixer

Sanitary Open Frame Mixer with easy access, tubular offset frame for mixing doughs up to 3,200 lbs.

Dough Chunker & Elevator

Designed with simplicity in mind, the extremely gentle rotary blade can be combined with belt transfer systems up to 30,000 lbs./hour.

Raw Dough Conveyor

Customized by application to transport dough from chunker or pump to downstream operations.

Tromp Laminating Line

Offering high-speed, stress-free or extrusion laminating for the production of croissants, pastries, danish, and puff pastry products.

Tromp Stress-Free Sheeting Line

Offering high-speed, stress-free production of consistently moulded products.

Tromp DecoJet 2

Specially designed for cutting proofed dough by means of water.

Den Boer Multibake Tunnel Oven

Pre-assembled, modular Den Boer tunnel ovens designed with independent zone control for more precise temperature control.

Vesta Spiral Cooler

Custom-configured with the most sanitary, modular design elements for a variety of product applications.

A-Series Conveyor

Designed for high operating efficiency and low maintenance, the A-Series Conveyors are built with anodized aluminum beaded plates and rust-free materials.

Vesta Spiral Freezer

Custom-configured with the most sanitary, modular design elements for a variety of product applications.

Product Diverter

Separates pans and lids into two or three lines with up to 35 actions per minute.

HS40 Bulk Bun Packer

Flexible and easy changeover, designed with regrouping section, vacuum evacuation,and hot air side seal.

Bulk Bun Basket Loader

Smooth elevator package transfer with single and double stack capabilities for high-speed bulk products.

Basket Denester

Servo technology automatically separates cross-nested baskets after discharge from Bottom-Out Basket Unstacker up to 34 baskets per minute.

Single Tunnel Basket Washing & Drying System

Flexible layout continuous washing and drying for improved resource conservation.

Bottom-Out Basket Unstacker

Handles up to 40 nested or cross-nested baskets per minute with adjustable widths for easy changeover.

Dry Trash Removal System

Configurable for “S” style, horizontal, or vacuum for more efficient and complete pre-sanitation waste removal.