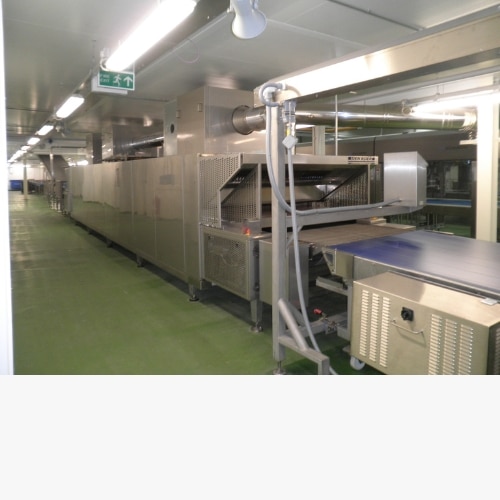

AMF Den Boer Multibake HT

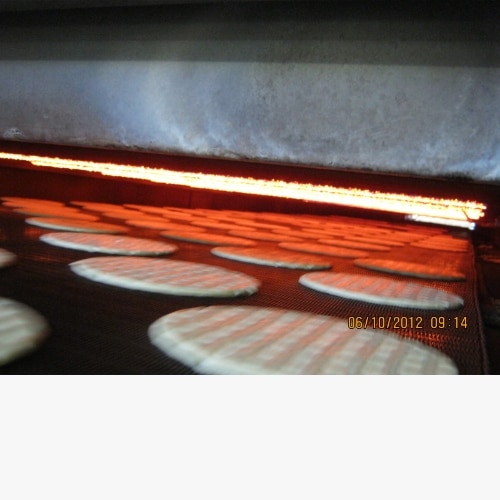

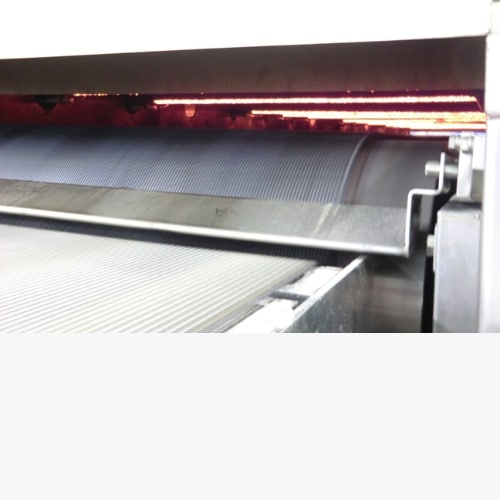

The Multibake® HT Tunnel Oven by AMF Den Boer is a high-temperature oven which reaches maximum of 500 °C or 932°F. Even under tough, confined operational conditions with the burner surface heated up to 1050°C, no flashback occurs. Because of the large opening angle of the burner, infrared radiation is evenly dispersed throughout the zone. This oven is commonly used to produce pre-baked products for foodservice and supermarkets, such as pizza, frozen pizza, flatbread, naan, pita, and more.

Multibake® HT is a typical tunnel oven solution for many applications in the food industry in which extremely high temperatures are needed in the baking process. This high-temperature tunnel oven offers the ability to bake at high temperatures in a production belt oven at high speeds.

Key benefits

- Baking time is contact time (belt pre-heat)

- Process temperature up to 500 °C

- Direct gas fired (natural gas & propane)

- Sanitation & maintenance access under the oven

- Modulating design (100-500 kW/m2)

- Independent belt pre-heat

- Lower total cost of ownership compared to conventional ovens

- Excellent color control due to IR technology

- Flawless product takeover at infeed and outfeed

Product Applications

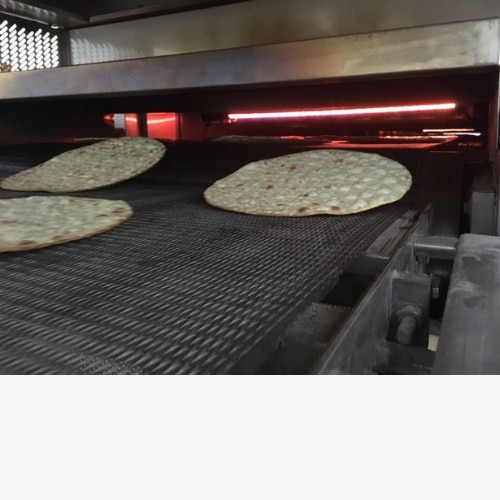

Perfect for Pizza Production

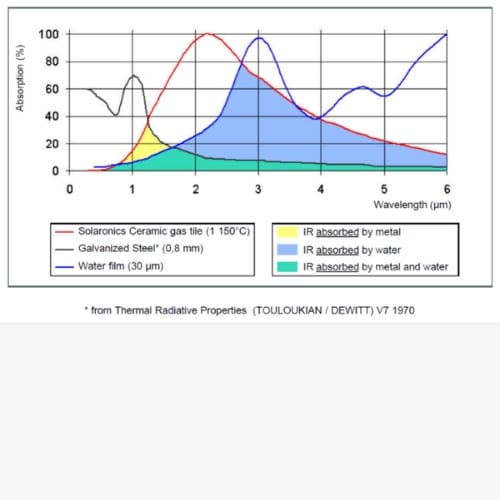

INFRARED RADIATION ADVANTAGES

- Direct transfer of energy from emitter to product

- High-power density

- Precise control and power modulation

- Advantages for process & industrial installation

- Local heating with energy savings

- Lower heating time

- Precise quantity of energy used

- Compactness (due to high-power density)

- Quality increase (in function of process type)

Optimal for creating a variety of products, including:

- Pizza

- Pizza Bases and Flatbreads

- Wraps

- Tortillas

- Thins

- Pita

- Lavash

- Taftoon

- Naan

- Roti

- Chapati

- Tunnbröd

- Barbari

- Sangak

- Focaccia

- Bagels

- Sandwich Thins

Request More Information About the Den Boer Multibake® HT Tunnel Oven

At AMF Den Boer, we’re committed to supporting bakeries around the world with the highest quality equipment to optimize operations, improve product quality and grow your bakery. Fill out this form to connect with an AMF Den Boer specialist.