AMF Den Boer Multibake IR

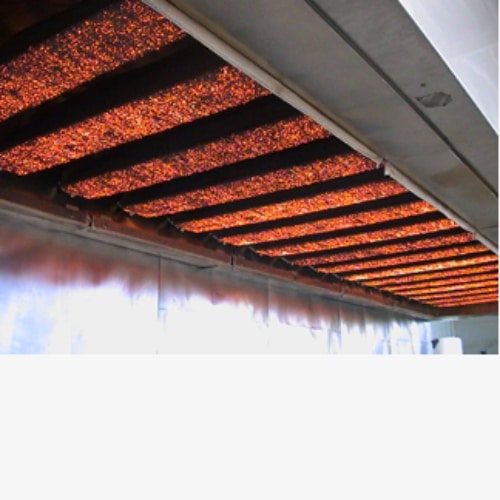

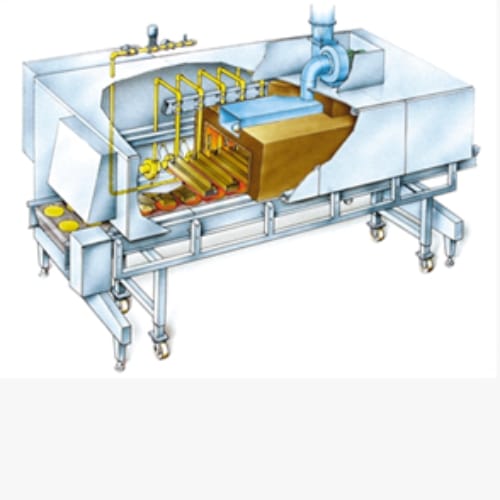

The Multibake® IR Tunnel Oven by AMF Den Boer is an infrared melter, dryer, and toaster for a variety of products. For drying, toasting, fixating, or melting products on one side, the infrared (IR) oven is optimal with low-end execution. The product surface will be intensely heated by means of infrared radiant burners, fitted to a fixed frame positioned above a conveyor. The conveyor underneath the C-frame is mobile for optimal cleaning purposes.

Note: The operational side is set at the right-hand side, seen in the moving direction of the products. The conveyor must be taken out at the opposite side of the operational side for washdown execution. The operational side must be clear before design freeze date.

Key benefits

- Very short dwell times

- Quick heating & cooling times

- Mobile frame

- Modulating burners

- Pizza cheese melting

- Browning/drying

- Total washdown

Product Applications

Intense Heat for Short Dwell Times

HEAT TRANSFER CONTROL

The heat transfer to the product can be varied in two ways. The first method is to regulate the air/gas supply to the burners by means of a central burner air ventilator. The Honeywell (combined valve, ignition, gas zero-pressure regulator) performs all the functions required for safe ignition, flame supervision, and pressure regulation. The gas/air mixing and regulating the gas/air flow to the burner is executed by means of a burner-air valve motor in combination with an AMF Den Boer burner air/gas mixing device. Each burner has its own Honeywell system. Modulation is always obtained by changing the amount of airflow; the gas flow will follow the airflow in the pre-determined ratio. The Honeywell burner control units can be operated from the control panel.

The second possibility is to regulate the speed of the conveyor. The slower the conveyor, the longer the radiation time and, thus, the amount of energy transferred to the product. Changing the speed of the conveyor means also changing of the production capacity of the IR tunnel. Note: If the speed will be set higher than the supply conveyor, the pattern of products might be disturbed.

With the Multibake IR tunnel oven, you can produce:

- Toast Bread

- Sandwich Bread

- Flatbreads

- Pizzas

- Meringue Browning

- Croque Monsieur

Request More Information About the Multibake IR Tunnel Oven

At AMF Den Boer, we’re committed to supporting bakeries around the world with the highest quality equipment to optimize operations, improve product quality, and grow your bakery. Fill out this form to connect with an AMF Den Boer specialist.