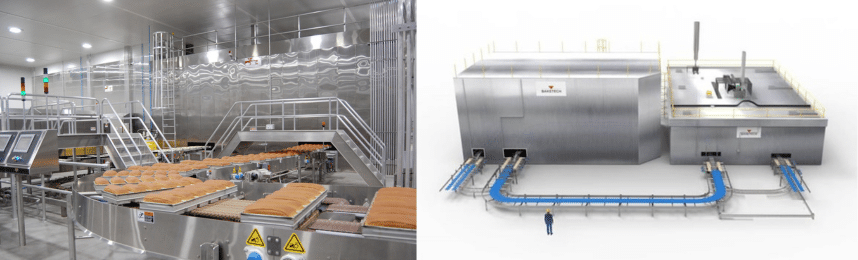

At AMF Bakery Systems, we provide exceptional system solutions for industrial bakeries worldwide. As part of our commitment to sustainability, we developed the first-ever industrial hydrogen oven, allowing our clients to minimize food and energy waste. Our team at AMF Sherbrooke specializes in creating custom-made machines for international customers, including mixers, conveyors, coolers, bread slicers, and baggers. We offer a dynamic work environment and exciting opportunities to join our team, including a position for a Drafter.

About The Role:

As a Mechanical Engineering team member, you will work under the supervision of the product group leader to design parts and assemblies and complete drawings of details corresponding to different bakery equipment. You will have to meet specific deadlines to meet our customers’ requirements. You will also collaborate with the product owner for estimating, planification, and manufacturing monitoring.

Primary Duties:

- Design and improve machines according to the instructions of the platform manager

- Develop and verify detailed drawings by 3D and 2D from preliminary concepts, sketches, engineering calculations, or other data

- Consult catalogs, different reference tools, and suppliers to select the components of the drawings

- Repairs sketches from surveys on machines for drawings

- Participate in solving technical issues on research and development projects and in product improvement

Knowledge:

- Solid Edge and Autocad software

- Engineering knowledge of materials properties as well as mechanical, pneumatic, and hydraulic bases

Required Skills:

- Interpersonal skills (colleagues and clients)

- Organized

- Creativeness

- Self-reliant

- Sense of priorities

- Quality oriented

- Write and speak advanced French and basic-level English

Experience:

- Mechanical engineering or industrial design technique with 2-5 years of experience

AMF Sherbrooke est le plus important fabricant de machines pour boulangeries industrielles en Amérique. L’usine de Sherbrooke conçoit et fabrique sur mesure des machines pour sa clientèle internationale. Elle innove et se développe constamment afin de demeurer le chef de file dans son secteur d’activité. AMF Canada emploie plus de 150 employés à Sherbrooke, offre un environnement de travail dynamique et vous offre la possibilité de faire partie de son équipe.

Raisons d’être du poste:

Sous la supervision votre superviseur immédiat comme membre de l’équipe. Vous êtes responsable de concevoir des équipements de boulangerie industrielle ainsi que de compléter des dessins de détails correspondants à différents équipements. Vous aurez à rencontrer des échéanciers précis. Vous aurez à collaborer avec le RP pour l’estimation, la planification et le suivi de fabrication.

Fonctions essentielles et principales tâches:

- Produire des dessins assistés par ordinateur 3D et 2D

- Concevoir et à l’améliorer les machines selon les instructions du responsable de plateforme

- Faire les corrections aux dessins selon les demandes du responsable

- Effectuer des esquisses à partir de relevés sur les machines

- Participer à la résolution de certains problèmes techniques liés aux dessins

- Effectuer les inspections des machines en production afin de valider la conformité des plans

Connaissances:

- Conception assistée par ordinateur (Solid Edge et Autocad) solid work ok-logiciel 3d

- Connaissance des techniques de fabrication des propriétés de matériaux ainsi que des bases en mécanique, pneumatique et hydraulique (Atout important)

Habiletés:

- Autonomie, Sens des priorités

- Créativité, organisé

- Rigoureux et soucieux de la qualité

- Avoir l’esprit d’équipe

Aptitudes/Attitudes:

Langues écrites : Français avancé et anglais intermédiaire (atout)

Langues parlées : Français avancé et anglais intermédiaire (atout)

Qualifications:

- Technique génie mécanique ou Dep en dessin industriel

- 2- 5 ans minimum d’expérience

Avantages :

- Cotisation de l’employeur à un RPDB de 4% annuellement

- Banque d’heures de maladie qui s’accumule à tous les mois de 3.33 heures pour un total de 40 heures après une année de service, maladie accumulable sur 2 ans jusqu’à un maximum de 80 heures

- 3 semaines de vacances à 6% + semaine à noël payée après 1 an

- Prime de 500 $ avec notre programme de référencement

- Assurances collectives (assurance invalidité de courte et longue durée, frais médicaux 80%, paramédicaux 100%, assurance voyage, assurance vie)

- Remboursement des cotisations à une association professionnelle

- Environnement ergonomique

- 12 jours fériés par année

- Affichage interne et possibilité d’avancement