AMF Den Boer Multibake R

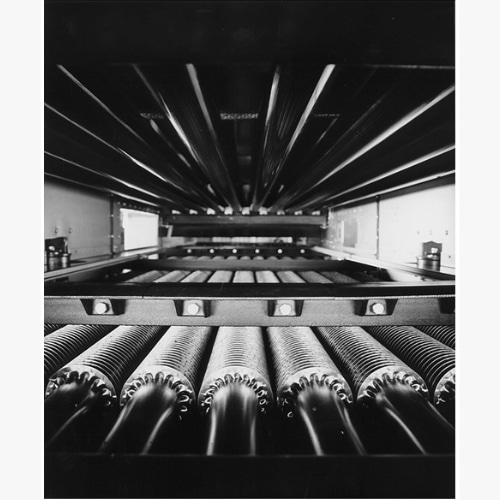

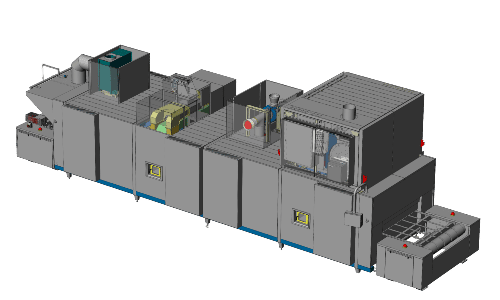

The Multibake® R Tunnel Oven by AMF Den Boer is an indirect heated oven (Radiation) for industrial bakeries. The required heat is generated outside the baking tunnel, preventing hot gases from coming into contact with the baking product. This heating system is also known as “Cyclotherm” or heat cycle.

The oven is divided into zones or sections. Within each zone, different temperature and humidity conditions are possible. This makes it possible for each zone to have a different function: rising, baking, and coloring of the products. Depending on the product to be baked, forced convection, either from the top or the bottom of the product, can be added to the execution.

This oven is also available with a Dual Fuel Option, featuring independent heating systems within the same oven.

Key benefits

- Hygienic design of the industrial tunnel oven with complete oven framework, including infeed/outfeed terminals, free from the bakery floor.

- Modular concept of pre-assembled modules and 100% electrical testing at AMF Den Boer prior to shipping ensures a very short installation and start-up.

- Optional top or bottom convection (even both in one zone) provides controllability of heat transfer to the product with more even baking and coloring of the products.

- Industrial Honeywell (Maxon) burners with a control ratio of 36:1 (300 kW) and 25:1 (600kW) give a wide span of operation and reliable control.

- Integrated temporary setpoint reduction in case of small gaps in the production flow.

- Several options are available for energy management and moisture measurement.

Product Applications

Request More Information About the Den Boer Multibake R Tunnel Oven

At AMF Tromp, we’re committed to supporting bakeries around the world with the highest quality equipment to optimize operations, improve product quality and grow your bakery. Fill out this form to connect with an AMF Tromp specialist.

Access the Den Boer Tunnel Oven Brochure