AMF supports bakeries in meeting seasonal demand fluctuations on multiple fronts. First, AMF collaborates with bakeries to tailor equipment solutions for managing seasonal demand fluctuations,…

Scaling Commercial Baking Production for Bakery Growth

In the dynamic world of commercial baking, maintaining quality and consistency while scaling production for bakery growth presents a significant challenge. In response to that challenge, AMF Bakery Systems offers innovative technological and customer care-driven solutions to help bakeries manage production changes while ensuring equipment runs at optimal levels for increased productivity and longevity.

Innovation that Aids In Scaling Commercial Baking Production and Bakery Growth

AMF-UX and Streamlined Data Eases Bakery Growth

AMF’s globally standardized operator interface significantly enhances the user experience across integrated bakery systems. This interface simplifies managing and scaling production, which directly contributes to bakery growth by making it easier for operators to monitor and adjust production processes as needed.

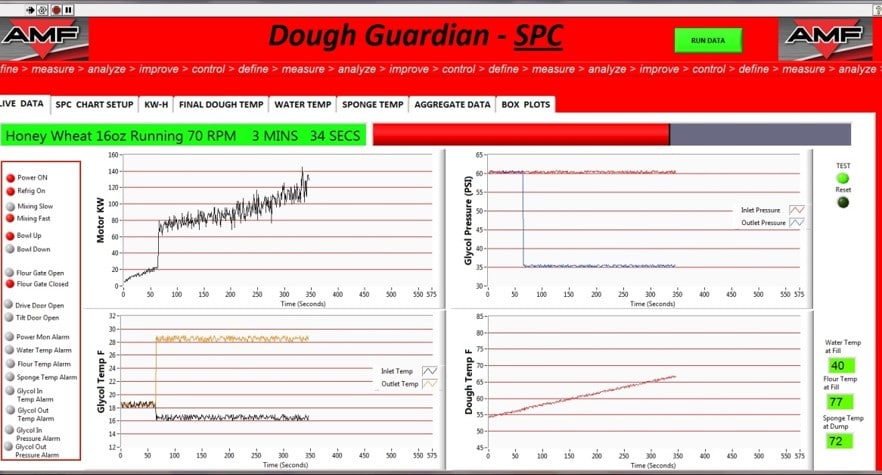

Real-time Data Allows Bakeries to Make Decisions and Scale with Ease

In addition to an easy-to-use interface, AMF also provides bakeries with enhanced bakery system data through AMFConnect, which gives bakery equipment operators real-time bakery system data and unit equipment information to make informed operation and maintenance decisions faster. The tool also connects bakery teams to further streamline operations and pave the way for future scalability and growth.

Lights Out Bakery: The Future of Baking and Bakery Growth

AMF Bakery Systems envisions the “lights-out bakery” as a revolutionary concept aimed at enhancing both quality and sustainability by significantly reducing the need for manual intervention during the baking process. This forward-thinking approach leverages AMF’s Bakery Intelligence technologies to automate critical aspects of bakery operation. By integrating data-driven insights and automation, bakeries can achieve remarkable consistency and efficiency, even as they scale production. This autonomous bakery model not only supports bakery growth by ensuring that bakeries can adeptly manage demand fluctuations but also aligns with sustainability goals through smarter energy usage and reduced waste. AMF’s commitment to innovation is paving the way for bakeries to transition towards more sustainable, efficient, and profitable production methodologies, marking a significant leap in how the baking industry approaches growth and operational excellence.

Smart Bakery Equipment for Predictive Maintenance

Traditionally, bakeries would postpone preventive maintenance until after high-demand seasons, like the summer bun season for bakeries producing soft bread and buns. However, this practice of delaying maintenance risks unexpected downtime, which is costly for bakeries. To combat this trend, AMF’s smart bakery equipment utilizes machine data monitoring to preemptively identify when specific parts deviate from their optimal range or are not running as efficiently as possible. When AMF’s predictive maintenance sensors identify issues, operators are notified and can begin working on a solution to avoid lengthened or unexpected downtime. This approach not only safeguards bakeries from having to pause production, but also enhances the longevity of the equipment.

Lifecycle Support for Growing Bakeries

Even before an equipment order is ever placed, AMF works with industrial bakeries to determine their production needs both now and in the future. This ensures that the systems ordered are designed, programmed, and onboarded to meet current and future production needs – during busy seasons as well as slower production times.

After a bakery places an order with AMF, our team methodically onboards the bakery if they are a new partner and installs the new equipment, ensuring it is functioning properly and operators are well-equipped to manage the new units and systems. Beyond the initial onboarding phase, AMF’s Customer Care team provides ongoing support to bakeries through our Maintenance Partnership Program to ensure that bakery equipment continues running optimally. Through various service-level agreements and AMFMethod™, bakeries have access to comprehensive lifecycle support. This Customer Care commitment helps bakeries remain at peak operational efficiency, fostering an environment conducive to bakery growth and scalability.

The Role of AMF Flex in Commercial Bakery Growth

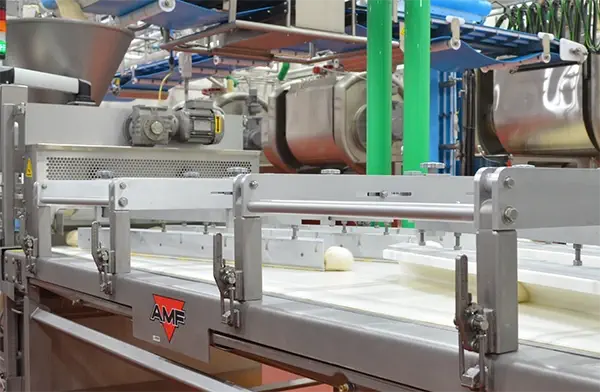

The precision of AMF Flex systems, operating within about 1% standard deviation of target weight consistently, ensures accuracy, efficiency, and quality as bakeries scale their production. This level of accuracy also increases savings on ingredients and energy, which drive down long-term operational costs.

AMF Flex: A Closer Look

AMF Flex’s core capabilities, including dividing, rounding, moulding, and intermediate proofing, are designed for unparalleled accuracy. This precision ensures that bakery items not only bake more evenly but also fit more seamlessly into packaging, streamlining the production line and reducing waste.

The user-friendly, recipe-driven technology enables quick and easy recipe changes, allowing bakeries to switch from one bakery output to another with as little as a few keystrokes so bakeries can easily go from producing hamburger buns to hot dog buns, for example. This ability to quickly change recipes demonstrates the system’s ability to adapt to bakery production requirements influenced by consumer .

Scaling Commercial Baking Production with AMF

AMF’s solutions are engineered to provide consistent quality across the entire system and between shifts, a cornerstone for achieving sustainable bakery growth. By utilizing AMF’s advanced technologies and comprehensive support, bakeries can confidently scale their production to meet market demands without compromising on quality or efficiency. Talk to an AMF representative today to learn more about how our solutions can help your bakery achieve the success you’re looking for.

FAQs

Q: How can AMF help my bakery scale production while maintaining quality?

AMF solutions are designed to help bakeries grow to meet increases in consumer demand, all while ensuring quality consistency. One of the key features that…

Q: What does the ordering process for new equipment look like?

Interested in scaling your bakery operations, but not sure where to start? A great way to kick things off is to contact us via our online…

Q: What does the modern commercial method of bread making entail? And how is it different from traditional bakery systems of the past?

There are several notable differences between modern commercial baking systems and those of the past, including: Speed and Efficiency: The production of baked goods has…

Q: I’m looking to scale my baking operations. How much does entry-level commercial bakery equipment cost?

Commercial baking equipment can vary widely in price depending on the type, size, and complexity of the equipment. For entry-level bread and bun production, AMF…

Q: Why should automation be implemented within a traditional bakery system?

Automation should be implemented within commercial bakery systems in order to increase efficiency, reduce labor costs, and improve accuracy. Automation can streamline time-consuming, repetitive tasks,…

Q: How do I know when it’s time to scale my bakery operations?

To know when it is time to scale your bakery operations, start by assessing the current demand for your products. Consider the following factors: Sales…