AMF Tromp Powershot Depositor

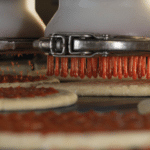

For Applying Tomato & White Sauces on Pizza, Focaccia, & Flatbreads

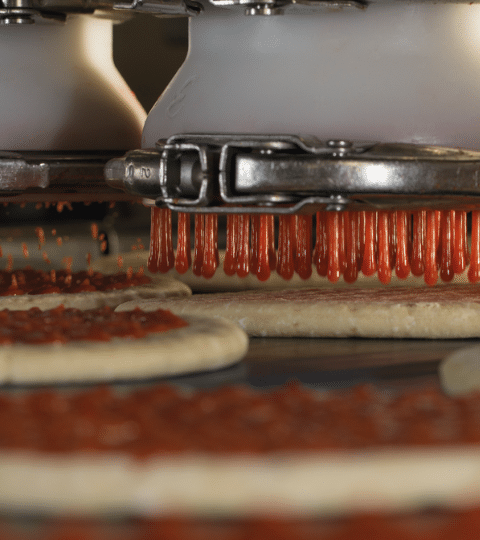

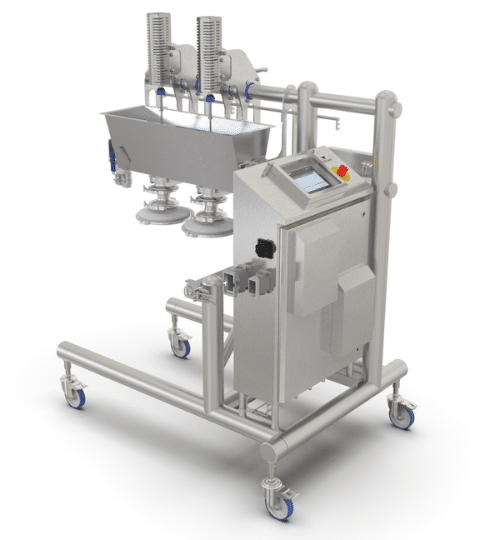

The Tromp Powershot Depositor dispenses targeted, smooth sauce on top of pizzas and empowers you to control sauce volume individually by lane for pre- and post-baking sauce application. Its “no product – no deposit” detection offers improved accuracy, even at high-speed production.

Key benefits

- “No product, no deposit” ensures accurate application and reduced ingredient waste.

- Independent lane control allows for recipe-based volume dispensing.

- Consistently centered and edge-free alignment of the deposit creates uniform products.

- Complete washdown capability aids in easy cleaning.

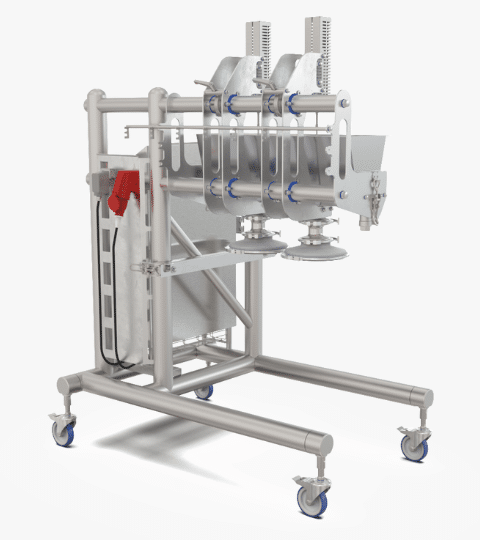

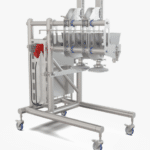

- Compact C-frame design allows for simple integration into existing production lines.

Product Applications

The AMF Tromp Powershot Depositor helps create various products and serves many applications in your bakery, including:

- Depositing tomato sauce

- Depositing pizza sauce

- Depositing crème sauces

- Pizza – regular sizes

- Focaccia

- Mini pizzas & pizza baguettes

Efficient & Sustainable Sauce Application

The Next Generation of Powershot Depositors

In alignment with AMF Bakery System’s quest for continuous improvement, AMF Tromp introduces the high-performing Powershot Depositor with elevated functionality and new features. Among the enhancements were:

- reduced cost of ownership, CO2 emissions, and noise

- no air consumption and mechanical wear due to air gap

- increased suction speed control and washdown capabilities

HIT THE TARGET EVERY TIME WITH

SIMPLE, PRECISE DEPOSITING.

AMF Tromp depositing solutions are available in multiple configurations, offering the precision required to handle various sauces. With flexible tooling and programming possibilities, you can achieve consistent, high-quality sauce application every time.

Access the Tromp Powershot Depositor Brochure