Decorating and Topping Solutions for Pizza Production

Pizza bakers work endlessly to meet growing consumer demand regarding convenience, indulgence, and healthy food trends. As pizza popularity grows worldwide, pizza producers look to automated technology to minimize labor and increase production capacity while maintaining the flexibility needed to make a wide variety of pizza and flatbread products.

AMF Tromp: Pioneers in Automated Pizza Make-Up Solutions

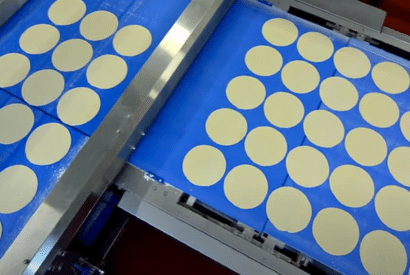

AMF Tromp, an AMF Bakery Systems brand, engineers automated pizza make-up solutions, including sheeting, decorating, depositing, and topping, so that bakers can produce the pizza or flatbread products consumers demand today with the flexibility and modularity needed for future portfolio growth. Read more to explore the benefits and possible solutions for your pizza topping or decorating process.

Benefits of Automating Pizza Topping and Decorating

Commercial pizza producers realize many benefits by automating their pizza topping or decorating process, including:

- Efficiency: automated pizza decorating solutions save time and increase production line efficiency

- Consistency: with the latest targeted topping solutions and digital solutions that utilize artificial intelligence to improve the process, achieving maximum product consistency in your pizza topping process has never been easier

- Cost Savings: reduce labor costs by automating repetitive topping processes as you scale bakery operations

- Variety: recipe-management software makes it simple to pre-program selections for a wide range of pizza products ensuring simple product changeover for your growing pizza portfolio

Without accuracy and calculated application, the topping portion of the pizza production process can be filled with time lost, product waste, and a diminished ROI.

Automated Pizza Productions Solutions

Many automated production solutions exist for commercial pizza producers looking to automate their decorating process, including:

- Conveyor-based Units: with simplicity and cost savings in mind, conveyor-based topping systems use one or more conveyor belts to transport pizzas under various topping dispenser units. They are best suited for high-volume pizza production.

- Tomato Sauce Enrober by AMF Tromp delivers even sauce distribution for any sauced-based baked pizza or flatbread across the entirety of the product base for optimal product quality.

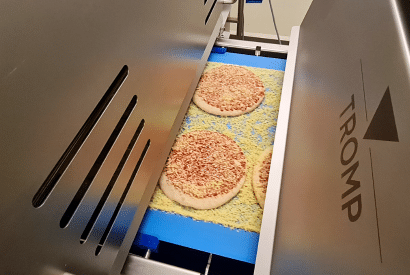

- Waterfall Applicator by AMF Tromp strews a smooth bed of food particles, including cheese, vegetables, and proteins. It utilizes a conveyor-based recirculation system to reduce product waste and a dispersing rake to provide independent quantity adjustments per ingredient.

- Target Applicator by AMF Tromp offers a higher degree of accuracy with a specially designed manifold to strew materials more accurately across each product with adjustability for each topping.

- Dosing Units: improve accuracy in pizza topping using digital, computer-controlled dispensing to apply precise amounts of sauce, cheese, vegetables, or proteins onto your pizza base. These units are easily customized and suited for high-volume production.

- Powershot Depositor by AMF Tromp is engineered with no product, no deposit detection that improves depositing accuracy and individually controls sauce volume by each lane. In addition, center depositing control ensures sauce is always properly centered on the dough, up to 200 strokes per minute in each lane.

- Topping Applicator Units: provide accurate, targeted computer-based topping distribution. These units are ideal when the accuracy of decorating is of significant concern, as with higher-cost ingredients. If the sauce, cheese, and toppings are not added evenly, and at the right weight, waste and inconsistency in the product can quickly arise. Due to the high cost of ingredients, pizza equipment manufacturers like AMF Tromp are using advancements in artificial intelligence, connectivity, and data processing to make pizza production more autonomous.

- Smart Applicator Solution by AMF Tromp automates manual operator weighing checks during the pizza topping process to keep ingredient applications within specifications. The Smart Applicator visually inspects each product and ensures the right amount of topping is applied without operator handling.

Seamless Integration with AMF Tromp Complete System Solutions

AMF Tromp decorating and topping solutions for pizza production integrate seamlessly with our complete system solutions to produce premium pizza products from mixer to marketplace. We build our AMF Tromp topping and decorating solutions so pizza makers can focus on consistent product quality, efficient production processes, and meet their bottom-line costs. We support modern bakeries by merging the virtual and physical worlds to drive optimization continuously. Through our expert baking experience, we are making equipment smarter, integrating processes, and improving bakery operations worldwide.

Explore Our Pizza Topping Solutions

Ready to automate your pizza topping and decorating processes? Explore AMF Tromp’s innovative solutions to enhance efficiency, consistency, and cost savings in your pizza production. Contact us to discuss your pizza project.