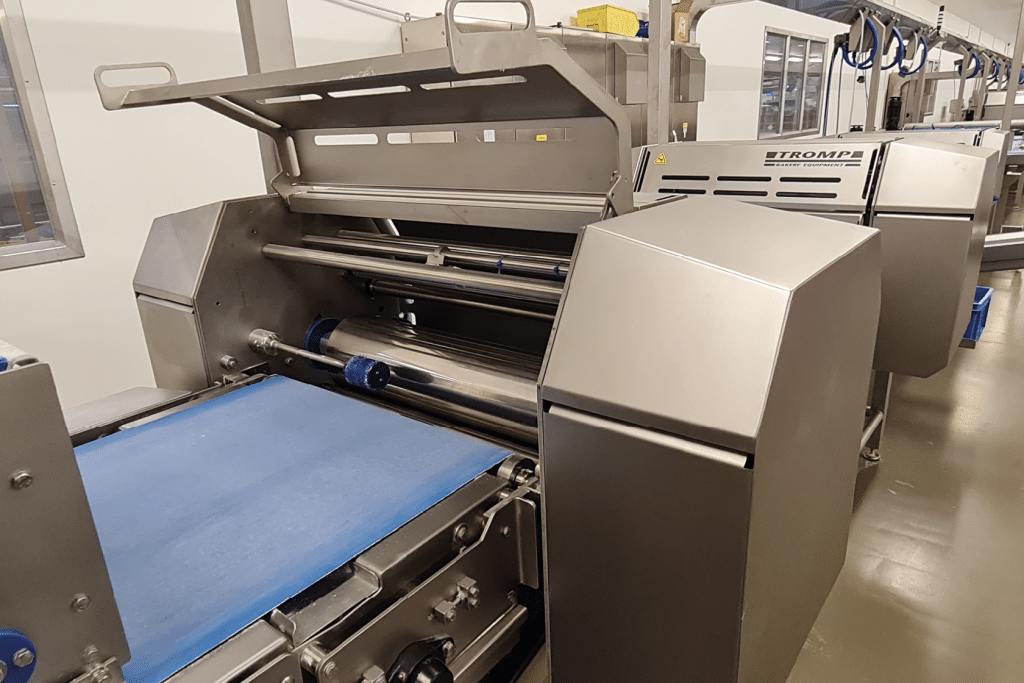

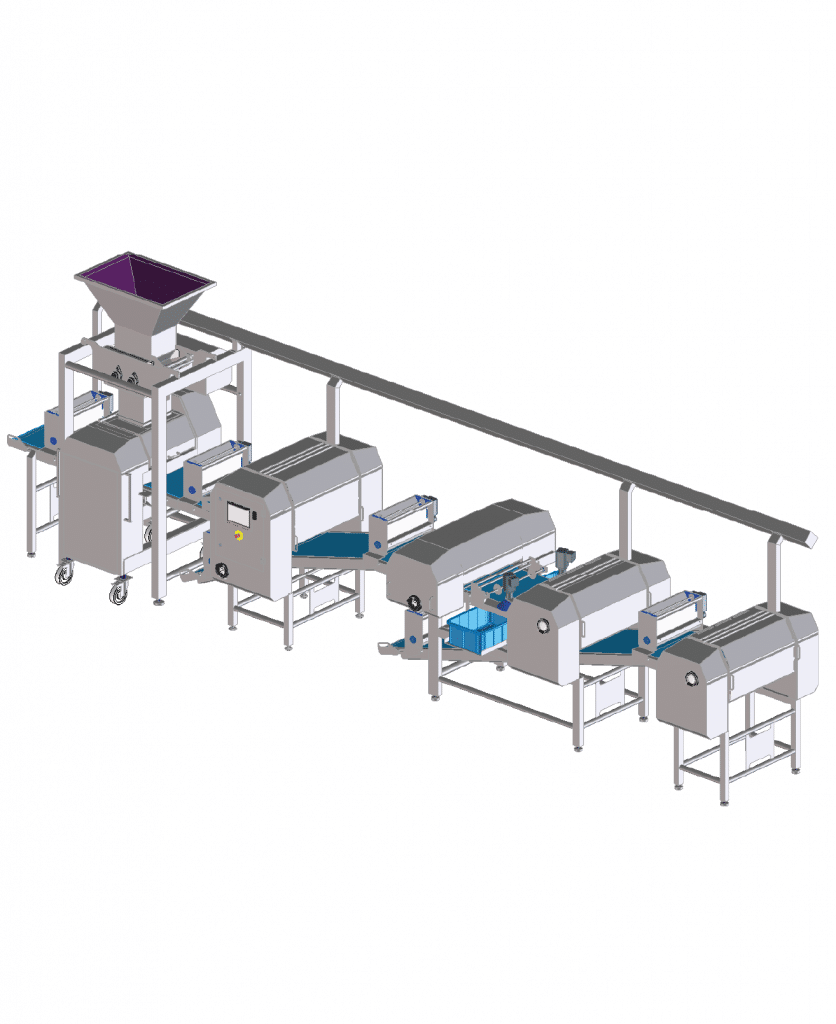

AMF Tromp Extrusion Sheeting line

for green or straight dough extrusion and reduction

If your products do not require extensive fermentation before the dough is processed, an extrusion & sheeting system might be what you need in your bakery. Chunks of dough are rapidly processed into a sheet for make-up and creating final products on this production line.

Key benefits

- Multi-functional sheeting solution for many dough types

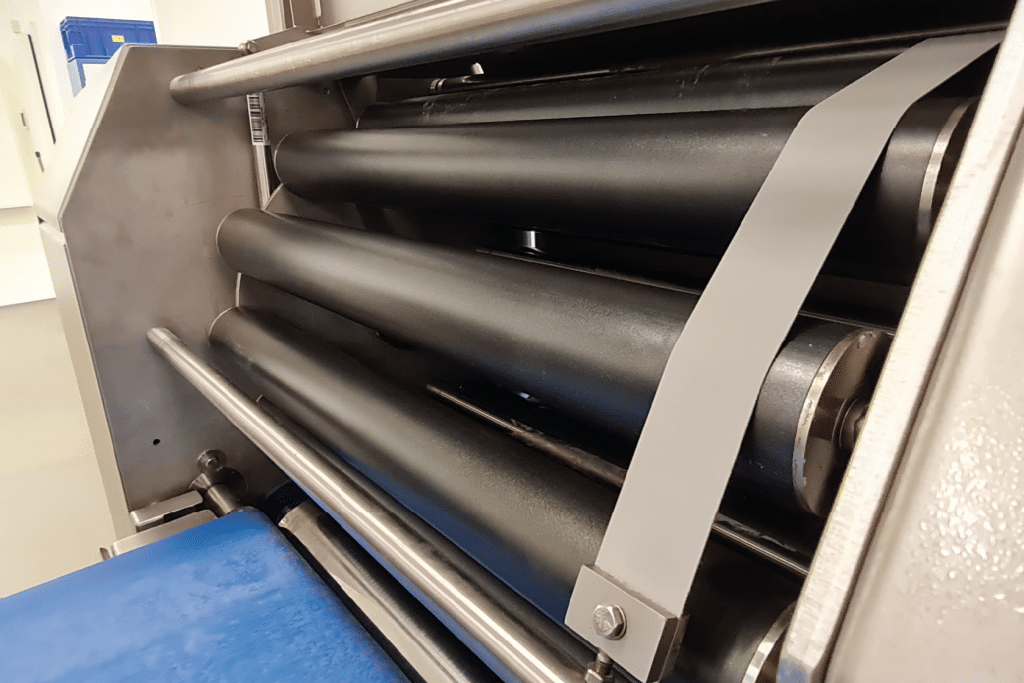

- Gentle extrusion of dough to keep dough properties intact

- Entry-level sheeting solution that offers excellent value for investment

- Up to 3-4 mm standard dough thickness

- Extra reduction station can be added to achieve 2-3 mm end thickness

- Scrap dough reworked in extrusion process for enhanced sustainability

Product Applications

Typical applications for Tromp extrusion sheeting systems include:

- Pizza Dough

- Par-baked Pizza Base

- Scones

- Pitas

- Naan

- Sheeted Bread

- Biscuit Dough

Equipment Specifications

Working Widths

Minimum of 600 mm

Maximum of 1,200 mm (in steps of 200 mm).

Max belt speed last section

20 mtr/minute

Kilos per hour

3 tons at 600 mm width with minimum end thickness of 4 mm.

6 tons at 1,200 mm width with minimum end thickness of 4 mm.

Access the Tromp EX Sheeting Line Brochure

Request More Information About the Tromp Extrusion Sheeting Line

At AMF Tromp, we’re committed to supporting bakeries around the world with the highest quality equipment to optimize operations, improve product quality, and grow your bakery. Fill out this form to connect with an AMF Tromp specialist.