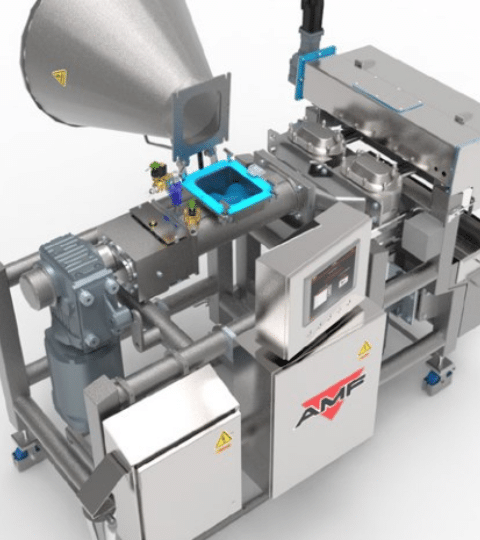

AMF Flex Dividers & Rounders

For Pizza Doughball Production

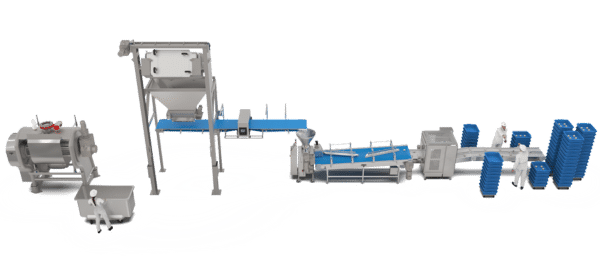

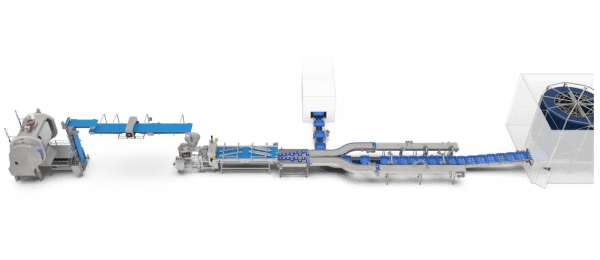

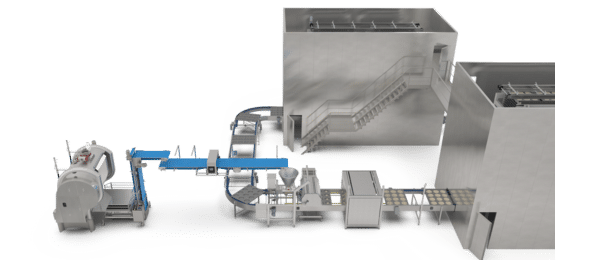

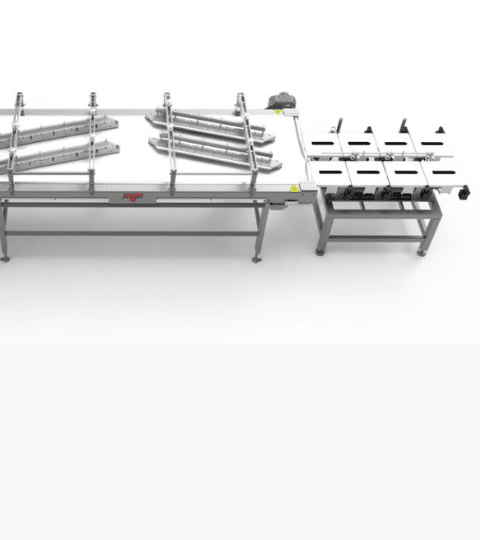

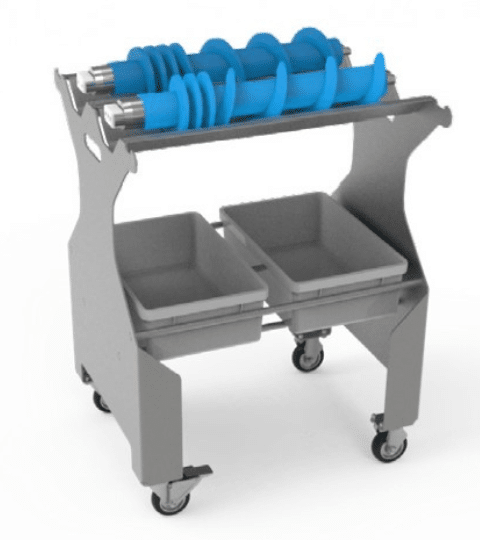

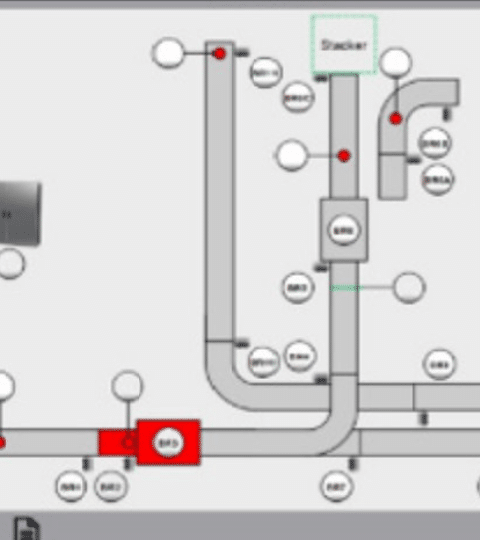

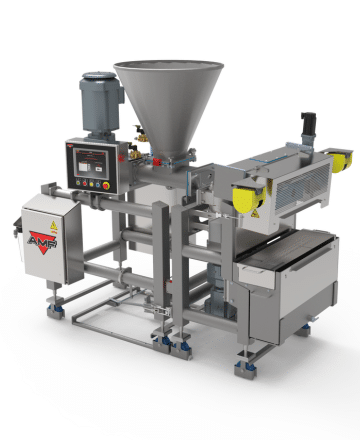

In the world of pizza-making, precision is the secret ingredient to crafting the perfect pie. AMF Flex offers compact extrusion dividing and rounding solutions for improved product consistency and scaling accuracy to scale doughball production for thin or American-style pizzas. AMF Flex doughball dividing systems are easily integrated with manual tray loading stations or with distribution to AMF’s Step Proofers or Spiral Freezers.

Key benefits

- Profitability: Increase profitability and reduce waste with unparalleled scaling accuracy, even at higher throughputs, catering to a wide range of dough types and pizza applications.

- Lower Operating Costs: Streamline your processes with intuitive, user-friendly HMIs and recipe management systems that reduce operating costs.

- Consistency: Achieve consistent results with repeatable product changeovers, including automated port speed settings.

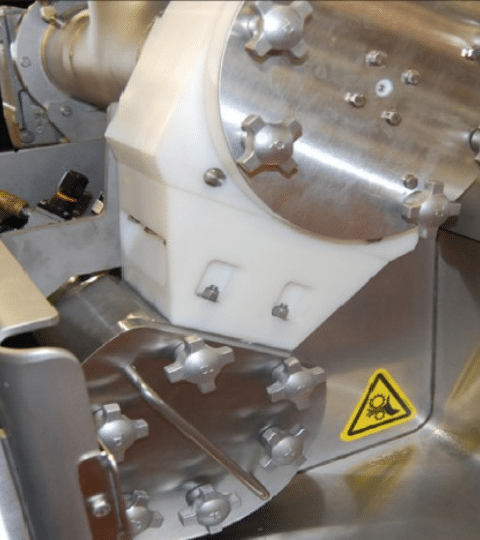

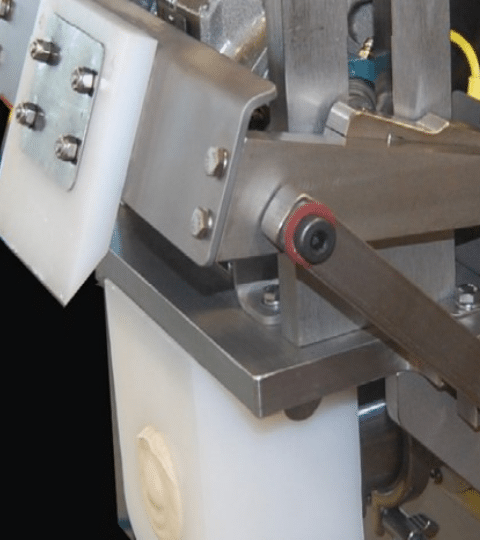

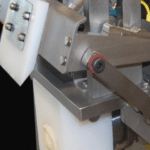

- Sustainability: Improve sustainability by embracing toolless sanitation procedures with easy access frame designs, eliminating the need for dusting flour or divider oil.

- Reduced Downtime: Experience reduced downtime and unparalleled support from our localized customer care team, ensuring your operations run smoothly.

Scale Pizza Doughball Production

Accuracy Meets Efficiency

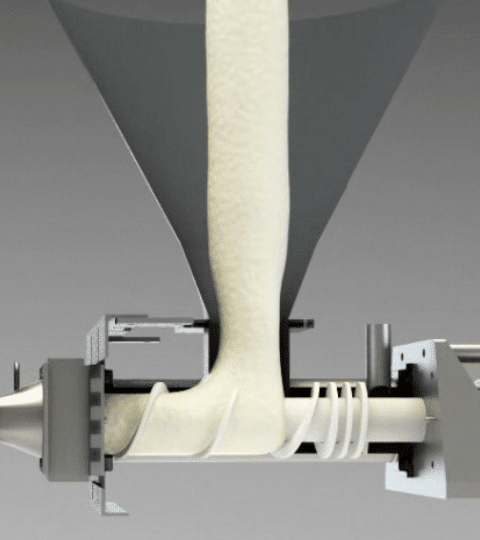

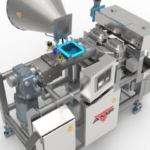

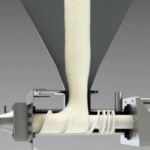

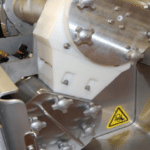

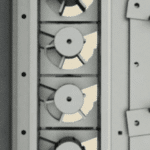

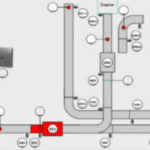

In our doughball production process, dough is divided into individual portions using a rotary cut-off knife and rounded by a sanitary belt rounder, resulting in perfectly portioned doughballs. For those seeking direct deposit solutions for pressed pizza applications, we offer options without rounding for distribution directly into trays.

What’s New at AMF Flex

Article

Article

Article

Access the Flex Pizza Doughball Systems Brochure

Request More Information About AMF Flex’s Pizza Doughball Production Equipment

At AMF Flex, we’re committed to supporting bakeries around the world with the highest quality equipment to optimize operations, improve product quality and grow your bakery. Fill out this form to connect with an AMF Flex specialist.